A kind of fiber grating etalon based on closed cavity metal plate temperature control and using method

A fiber grating and metal plate technology, which is used in special recording/indicating devices, and uses optical devices to transmit sensing components, instruments, etc., can solve the problems of fiber grating signal detection equipment being easily disturbed and unstable by the external environment, and achieve Expand the ambient temperature range, light weight, reduce the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

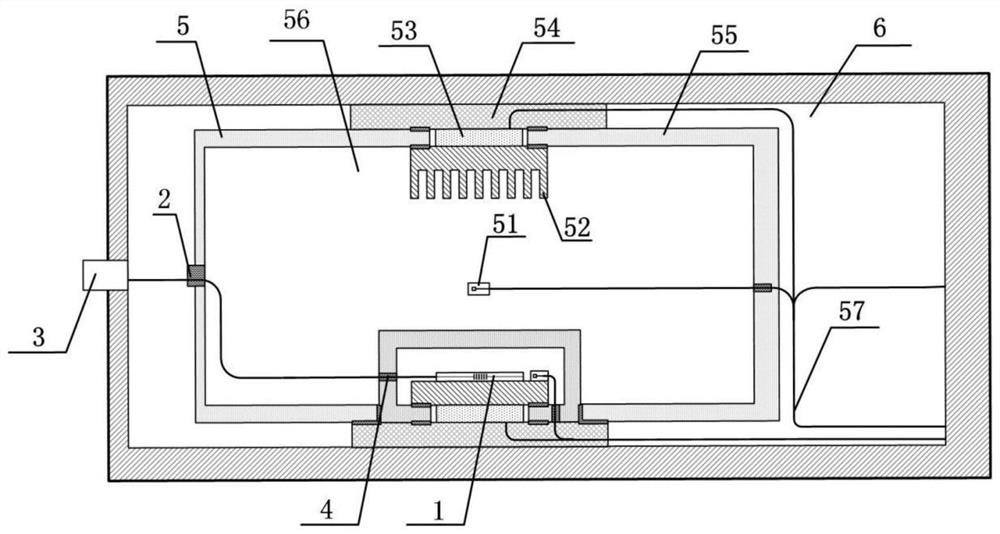

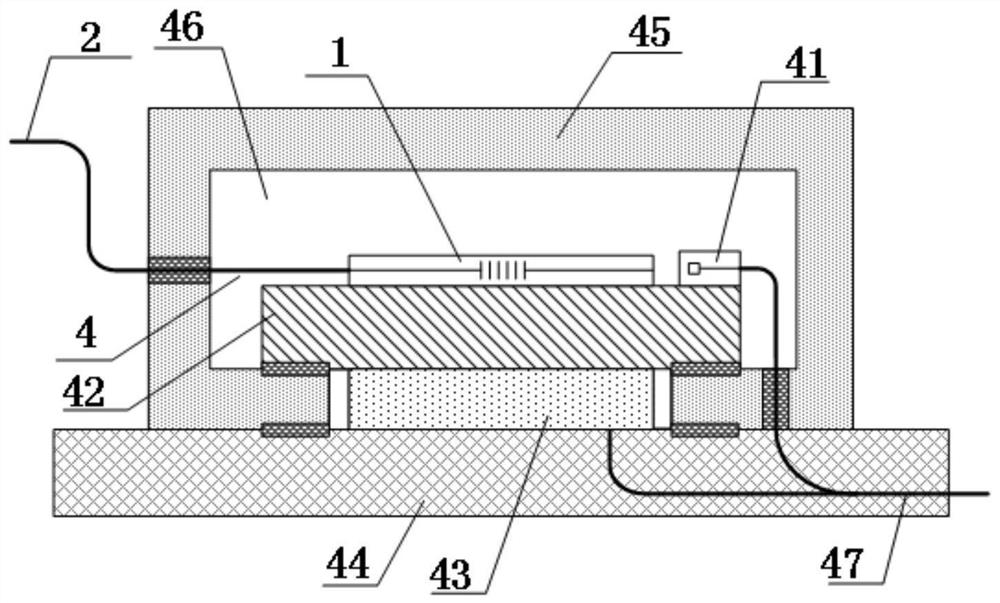

[0051] like Figure 1-2 As shown in the figure, a fiber grating etalon based on closed-cavity metal plate temperature control includes a sensitive element 1, an outgoing optical cable 2 and an optical fiber adapter 3 connected in sequence with the sensitive element 1, and a first heat preservation device connected with the sensitive element 1. 4, the second heat preservation device 5 arranged outside the first heat preservation device 4 and the case 6 outside the second heat preservation device 5, and the optical fiber adapter 3 is installed on the case 6;

[0052] The first heat preservation device 4 includes a stacked first temperature sensor 41, a first temperature control plate 42, a first refrigeration sheet 43 for heating and cooling, a first heat dissipation plate 44, a first heat preservation device outer frame 45, and a first heat preservation device. A sealed first heat preservation cavity 46 formed by the outer frame 45 of the device and the first refrigeration shee...

Embodiment 2

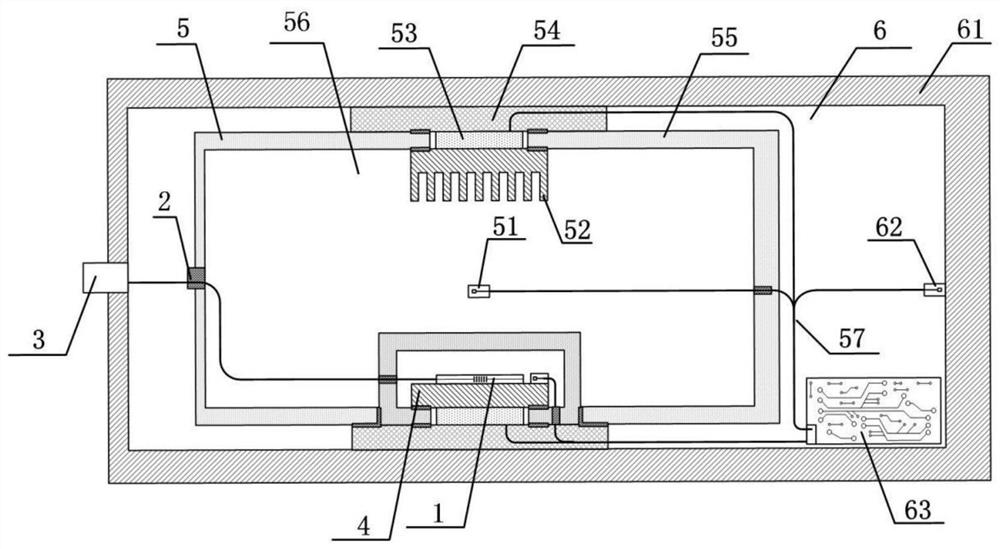

[0055] like Figure 2-3 As shown in the figure, a fiber grating etalon based on closed-cavity metal plate temperature control includes a sensitive element 1, an outgoing optical cable 2 and an optical fiber adapter 3 connected in sequence with the sensitive element 1, and a first heat preservation device connected with the sensitive element 1. 4, the second heat preservation device 5 arranged outside the first heat preservation device 4 and the case 6 outside the second heat preservation device 5, and the optical fiber adapter 3 is installed on the case 6;

[0056] The first heat preservation device 4 includes a stacked first temperature sensor 41, a first temperature control plate 42, a first refrigeration sheet 43 for heating and cooling, a first heat dissipation plate 44, a first heat preservation device outer frame 45, and a first heat preservation device. A sealed first heat preservation cavity 46 formed by the outer frame 45 of the device and the first refrigeration shee...

Embodiment 3

[0062] like figure 2 , 4 As shown in the figure, a fiber grating etalon based on closed-cavity metal plate temperature control includes a sensitive element 1, an outgoing optical cable 2 and an optical fiber adapter 3 connected in sequence with the sensitive element 1, and a first heat preservation device connected with the sensitive element 1. 4, the second heat preservation device 5 arranged outside the first heat preservation device 4 and the case 6 outside the second heat preservation device 5, and the optical fiber adapter 3 is installed on the case 6;

[0063] The first heat preservation device 4 includes a stacked first temperature sensor 41, a first temperature control plate 42, a first refrigeration sheet 43 for heating and cooling, a first heat dissipation plate 44, a first heat preservation device outer frame 45, and a first heat preservation device. A closed first heat preservation cavity 46 formed by the outer frame 45 of the device and the first refrigeration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com