Automobile battery box lower cover weld joint gas leakage position detection device and method

An automotive battery and testing device technology, applied in the field of machinery, can solve the problems of uneven distribution of welding seams on the lower cover of the battery box, difficult airtightness detection of airtight spaces, and high loss costs, so as to reduce the scrap rate, quickly detect and increase costs. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

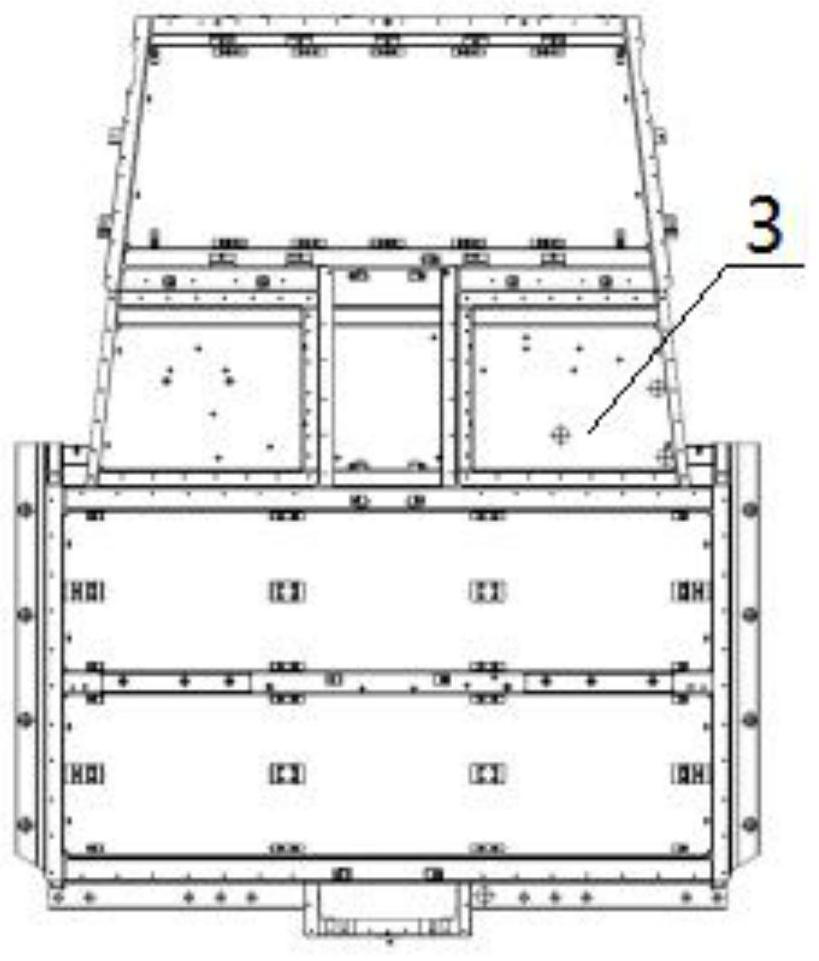

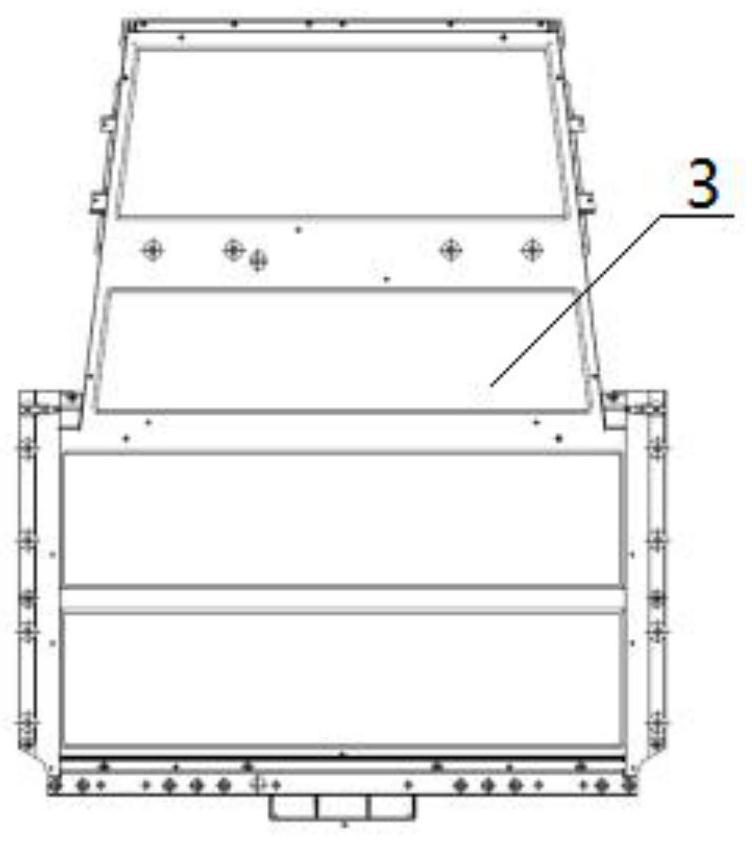

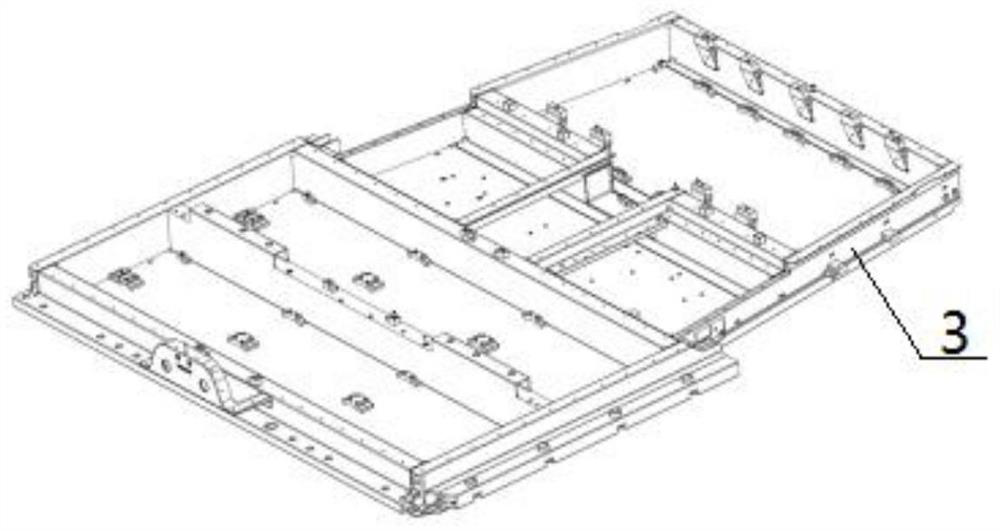

[0026] The invention provides a device for detecting the air leakage position of the welding seam of the lower cover of an automobile battery box, comprising a frame 1, on which an inflatable mechanism 2 is arranged, and the inflatable mechanism 2 is fixed on the frame 1 in a well-known manner, such as sticking Knotting, welding, buckle connection, etc., the battery box lower cover 3 is placed in the inflation mechanism 2, and the battery box lower cover 3 is completely embedded in the inflation mechanism 2, so as to realize the function of inflating and sealing the periphery of the battery box lower cover 3; The upper part of the inflatable mechanism 2 is provided with a sealing cover 4 that cooperates with it, and the sealing cover 4 forms a sealed cavity together with the lower cover of the battery box 3 and the inflating mechanism 2, so as to realize the function of leakage of all welds to be checked; Wherein, the gas inlet 5 is provided on the inflation mechanism 2, and th...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that this embodiment also includes a quick clamping mechanism 7, specifically, a quick clamping mechanism 7 is provided between the inflation mechanism 2 and the sealing cover plate 4, and the quick clamping mechanism 7 is Multiple, quick-clamp mechanism 7 is further used to fully press the sealing cover plate 4 with the inflation mechanism 2 and the battery box lower cover 3 to form a sealed cavity, and realize the function of detecting from the periphery of the battery box lower cover 3 to the inside .

Embodiment 3

[0032] This embodiment provides a method for detecting the air leakage position of the welding seam of the lower cover of the automobile battery box, and the steps are as follows:

[0033] S1: Put the lower cover 3 of the battery box into the inflatable mechanism 2; the lower cover 3 of the battery box is completely embedded in the inflatable mechanism 2;

[0034] S2: Install the sealing cover plate 4 on the upper part of the inflatable mechanism 2 to form a sealed cavity; preferably, the sealing cover plate 4 is quickly positioned with the positioning pin of the inflatable mechanism 2, and placed on the inflatable mechanism 2 and the lower cover of the battery box 3 above;

[0035] S3: Through the gas inlet 5, hydrogen gas with a concentration of 5% is passed into the sealed cavity;

[0036] S4: After a fixed period of time, use the leak detector to detect the weld; when the leak detector gives an alarm, it means that there is a gas leak at this position, which is the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com