Transparency film, optical material comprising same, and display device comprising same

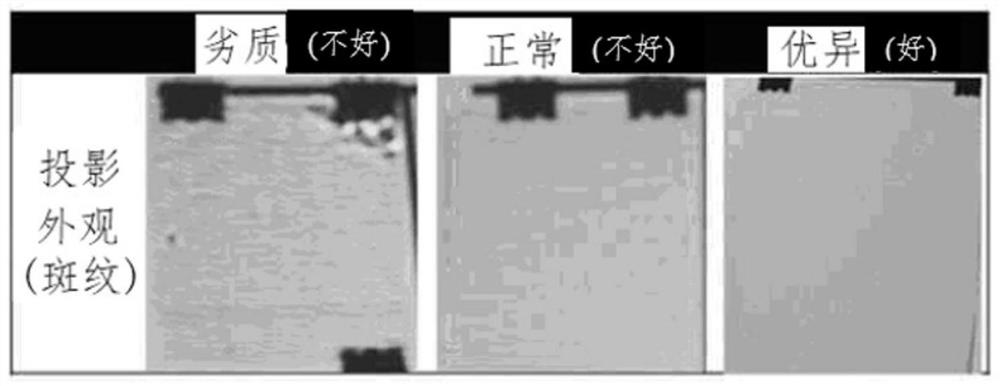

A transparent film and light-transmitting technology, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of reduced visual clarity of displays, poor visibility of polymer films, and image distortion of display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

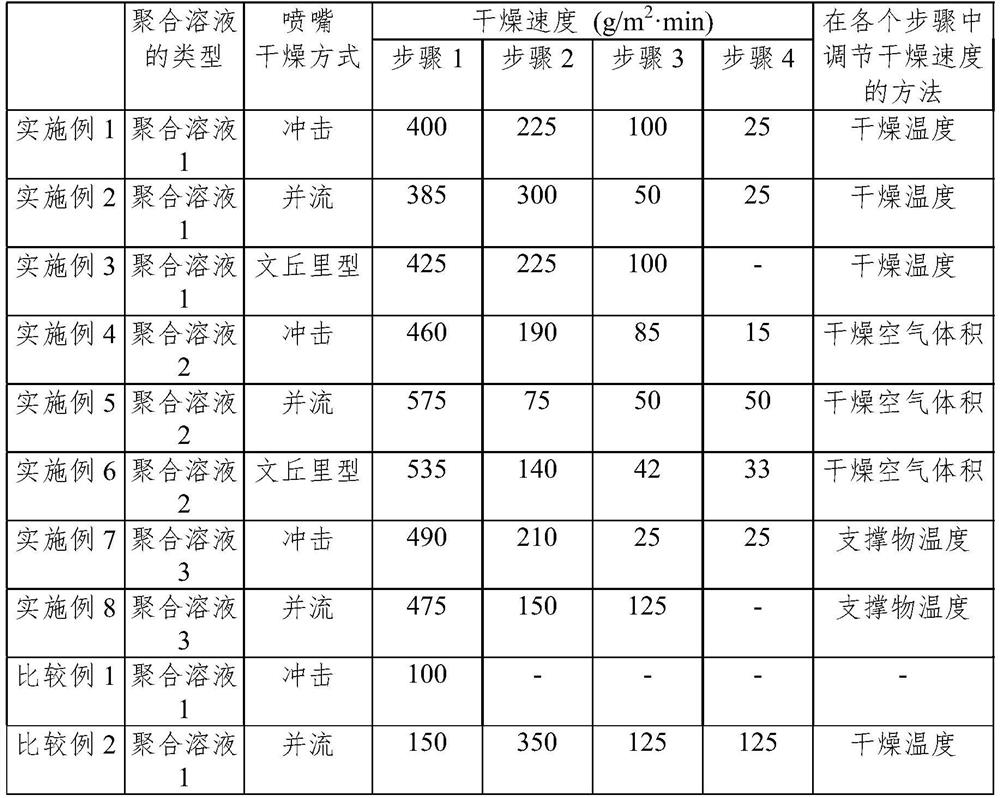

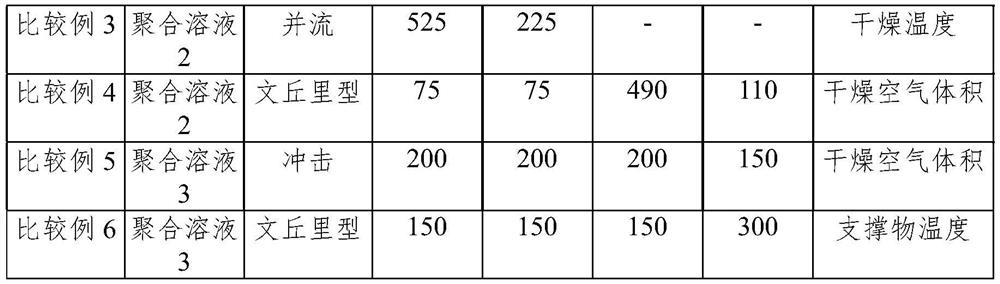

Examples

preparation example 1

[0118] [Molar ratio of TFMB:6FDA:TPC=100:14:86]

[0119] Dimethylacetamide (DMAc) and 2,2'-bis(trifluoromethyl)benzidine (TFMB) were added to the reactor under a nitrogen atmosphere and stirred well, and then 4,4'-hexa Fluoroisopropylidene diphthalic anhydride (6FDA) and stir well until dissolved. After that, terephthaloyl chloride (TPC) was added thereto, and the mixture was dissolved and reacted by stirring for 6 hours to prepare a polyamic acid resin composition. Here, the amount of each monomer was found to be the molar ratio of TFMB:6FDA:TPC=100:14:86, and the temperature of the reactor was maintained at 30°C. The finally obtained polyamic acid resin composition had a viscosity of 33000 cps. Then, pyridine and acetic anhydride were added to the polyamic acid resin composition at 2.5 times mole of the total amount of dianhydride added, and stirred at 60° C. for 1 hour to prepare a polymerization solution 1 .

[0120] Thereafter, the polymerization solution 1 was precipi...

preparation example 2

[0122] [Molar ratio of TFMB:CBDA:IPC=100:60:40]

[0123] Dimethylacetamide (DMAc) and 2,2'-bis(trifluoromethyl)benzidine (TFMB) were added to the reactor under nitrogen atmosphere and stirred well, then 4,4'-cyclo butanetetracarboxylic dianhydride (CBDA), and stir well until dissolved. Thereafter, isophthaloyl chloride (IPC) was added thereto, and the mixture was dissolved and reacted by stirring for 6 hours to prepare a polyamic acid resin composition. Here, the amount of each monomer was obtained as the molar ratio of TFMB:CBDA:IPC=100:60:40, and the temperature of the reactor was maintained at 30°C. The finally obtained polyamic acid resin composition had a viscosity of 90,000 cps. Then, pyridine and acetic anhydride were added to the polyamic acid resin composition in moles of 2.5 times the total amount of dianhydride added, and stirred at 60° C. for 1 hour to prepare a polymerization solution 2 .

[0124] Thereafter, the polymerization solution 2 was precipitated in ex...

preparation example 3

[0126][Molar ratio of TFMB:CBDA:IPC=100:40:60]

[0127] Dimethylacetamide (DMAc) and 2,2'-bis(trifluoromethyl)benzidine (TFMB) were added to the reactor under nitrogen atmosphere and stirred well, then 4,4'-cyclo butanetetracarboxylic dianhydride (CBDA), and stir well until dissolved. Thereafter, isophthaloyl chloride (IPC) was added thereto, and the mixture was dissolved and reacted by stirring for 6 hours to prepare a polyamic acid resin composition. Here, the amount of each monomer was found to be the molar ratio of TFMB:CBDA:IPC=100:40:60, and the temperature of the reactor was kept at 30°C. The finally obtained polyamic acid resin composition had a viscosity of 68000 cps. Then, pyridine and acetic anhydride were added to the polyamic acid resin composition at 2.5 times the mole of the total amount of dianhydride added, and stirred at 60° C. for 1 hour to prepare a polymerization solution 3 .

[0128] Thereafter, the polymerization solution 3 was precipitated in excess ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap