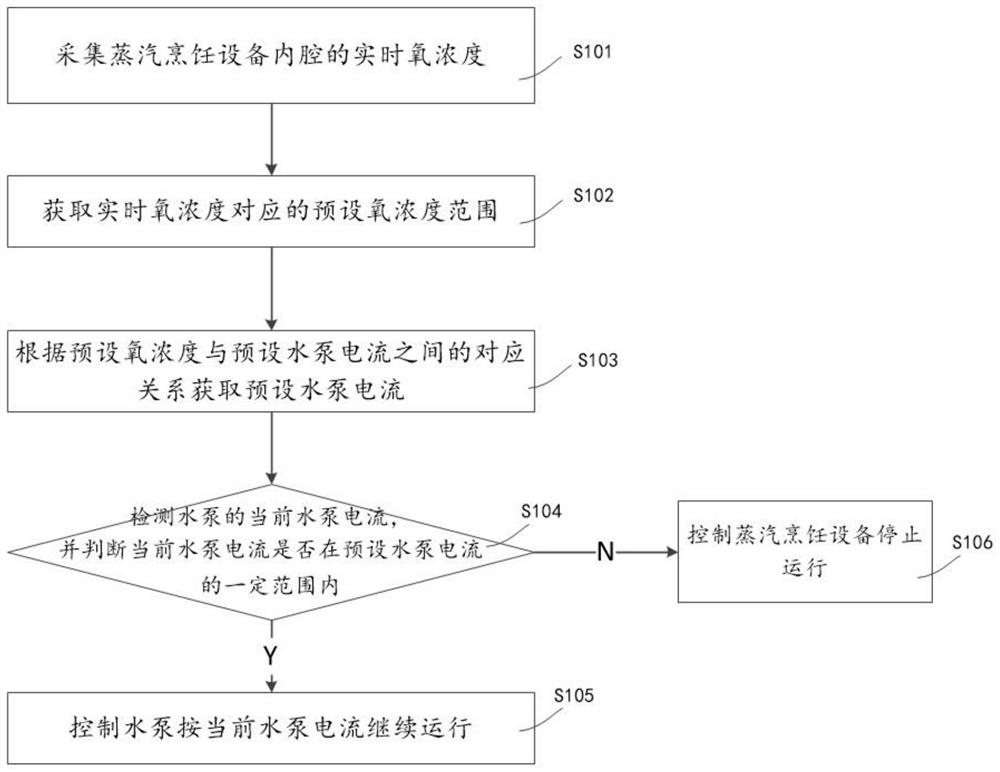

Control method of steam cooking equipment and steam cooking equipment

A technology of cooking equipment and control method, which is applied in the direction of steam cooking utensils, program control, computer control, etc. It can solve the problems of poor taste, long humidification time of the inner cavity, comprehensive control, etc., and achieve the effect of improving the taste of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

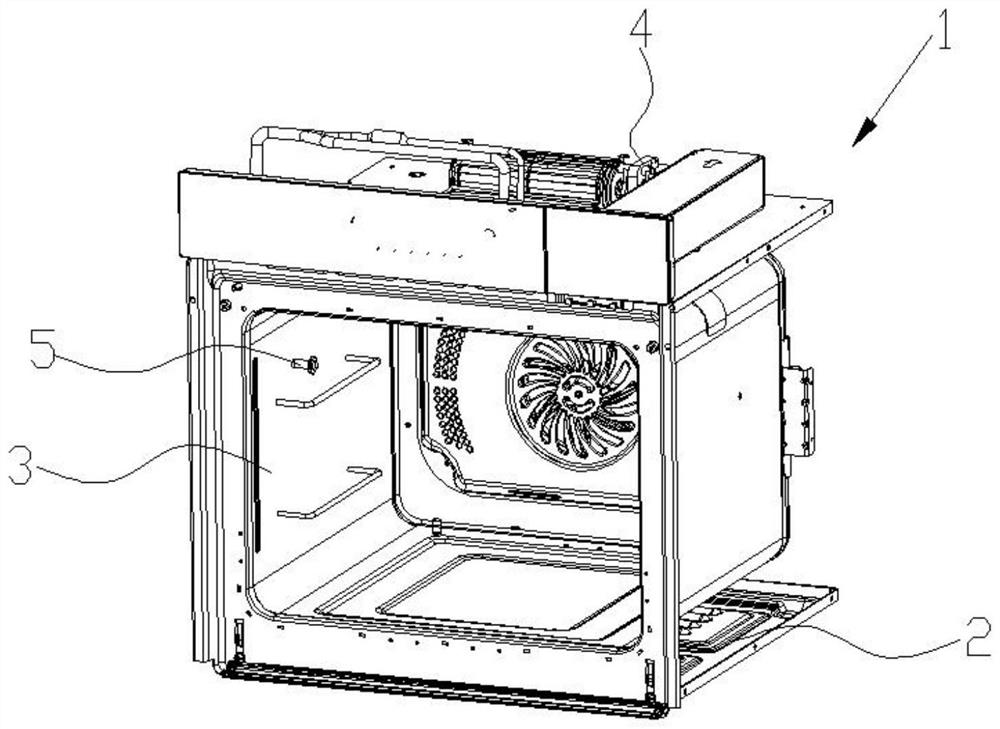

[0063] like figure 2 , a steam cooking device 1, comprising a housing 2, an inner tank 3, an oxygen sensor 5, a water pump 4, a current detection device and a controller, the oxygen sensor 5 is arranged on the side wall of the inner tank 3, the The water pump 4 is arranged between the inner tank 3 and the housing 2, the current detection device is used to detect the current flowing through the water pump 4, the controller and the oxygen sensor 5, the current detection device The device is electrically connected. By collecting the real-time oxygen concentration in the inner cavity of the steam cooking equipment, query which preset oxygen concentration range the real-time oxygen concentration falls into, and obtain the preset water pump 4 according to the relationship between the preset oxygen concentration and the current of the preset water pump 4 The current of the current water pump 4 is detected by the current detection device and judges whether the current of the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com