Dynamic characteristic evaluation system and method for partitioned fixed balancing weight in narrow space

A small space, fixed counterweight technology, applied in special data processing applications, instruments, design optimization/simulation, etc., can solve problems such as inability to weld and reinforce, lack of guidance process methods, and lack of dynamic evaluation methods for welding mass blocks. To achieve the effect of high accuracy, clear method and comprehensive analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

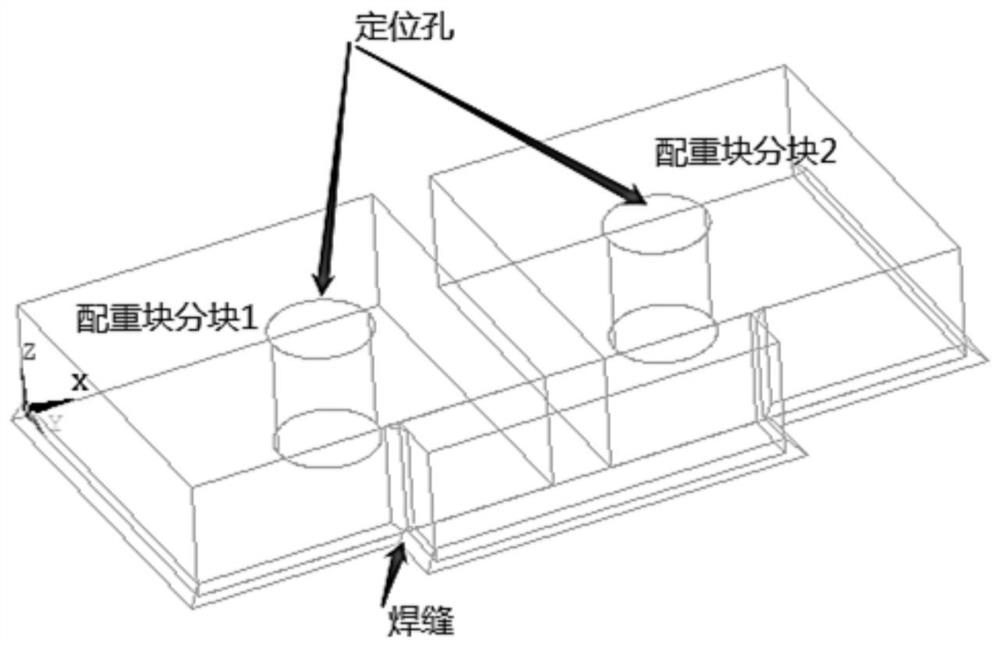

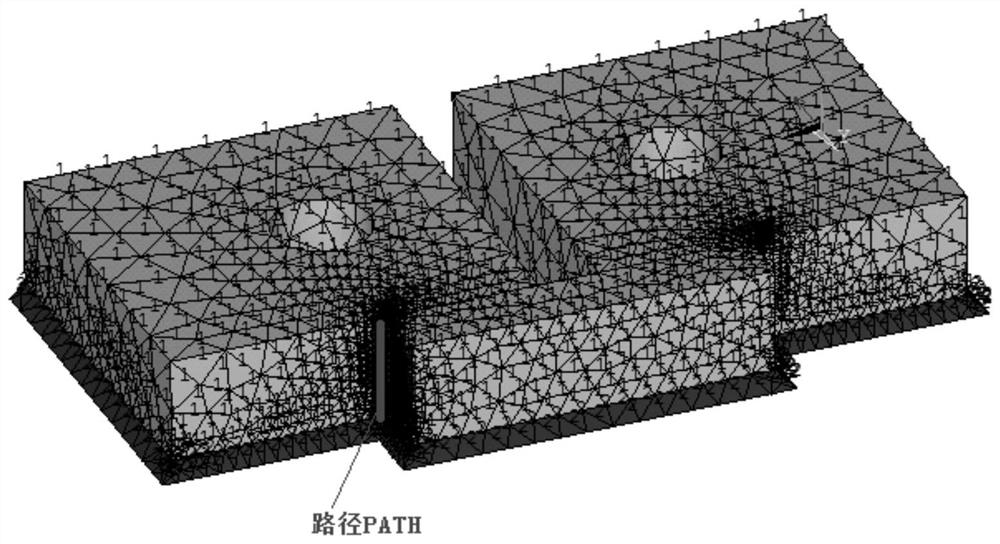

[0048] The system and method for evaluating the dynamic characteristics of the counterweight block of a vertical hydroelectric generator according to the present invention are composed of three-dimensional modeling software, finite element analysis software, a mechanical analysis unit, and a post-processing unit. Among them, the three-dimensional modeling software is responsible for establishing the geometric model of the counterweight and the weld; on the basis of this model, the finite element analysis software is imported to model the tested product, divide the grid, give boundary conditions, debug and calculate. Set the PATH for the weld in the post-processing module, then map the elements to the path, and use the curve to describe the response of the stress concentration.

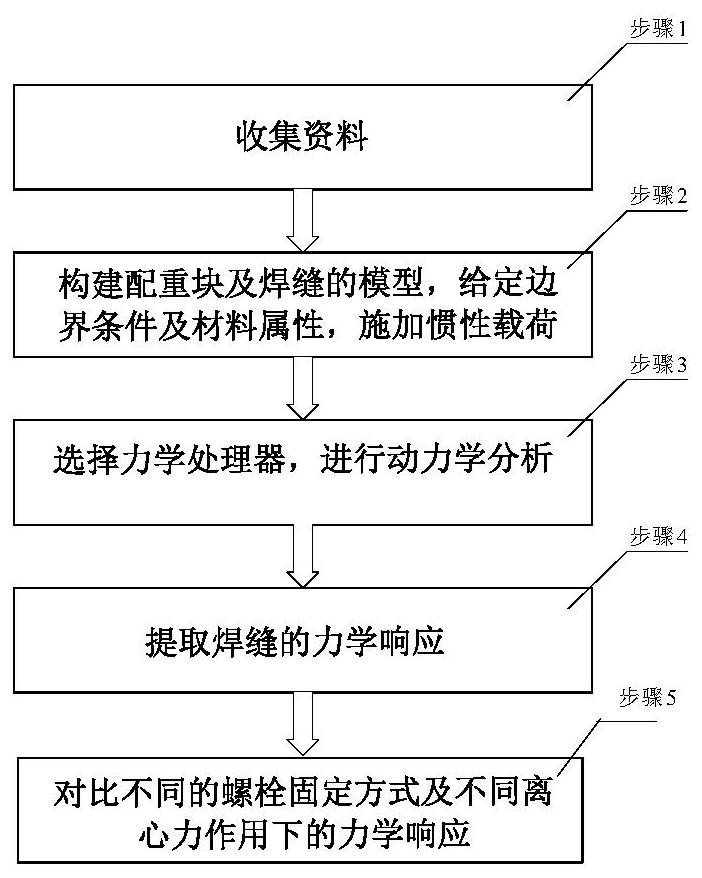

[0049] refer to figure 1 , combined with an example, the system and method for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com