Passivation method of battery piece

A technology of battery sheet and potassium hydroxide, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as battery efficiency decline, and achieve the effect of improving battery sheet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It can be seen from the background art that the efficiency of the cut battery sheet in the prior art needs to be improved.

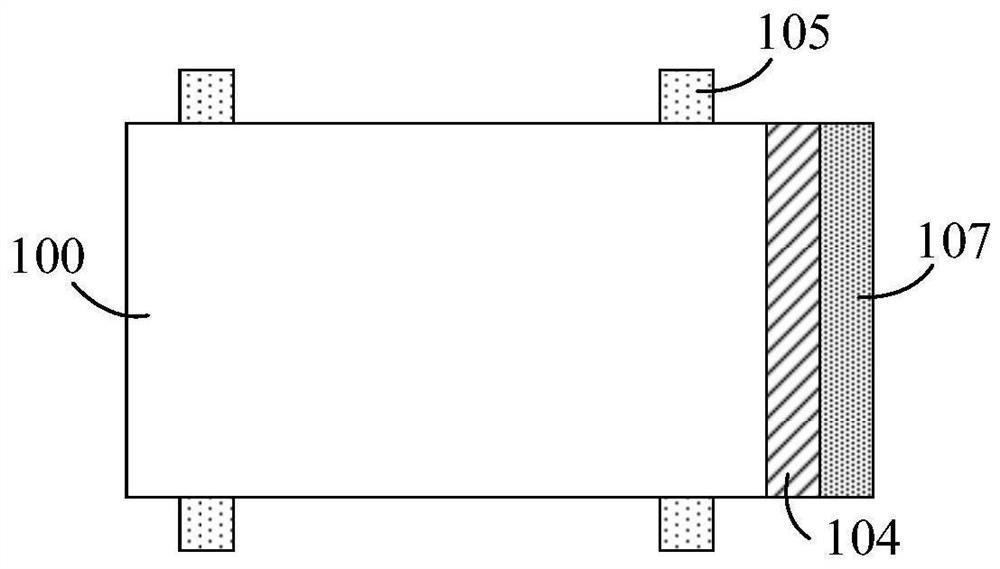

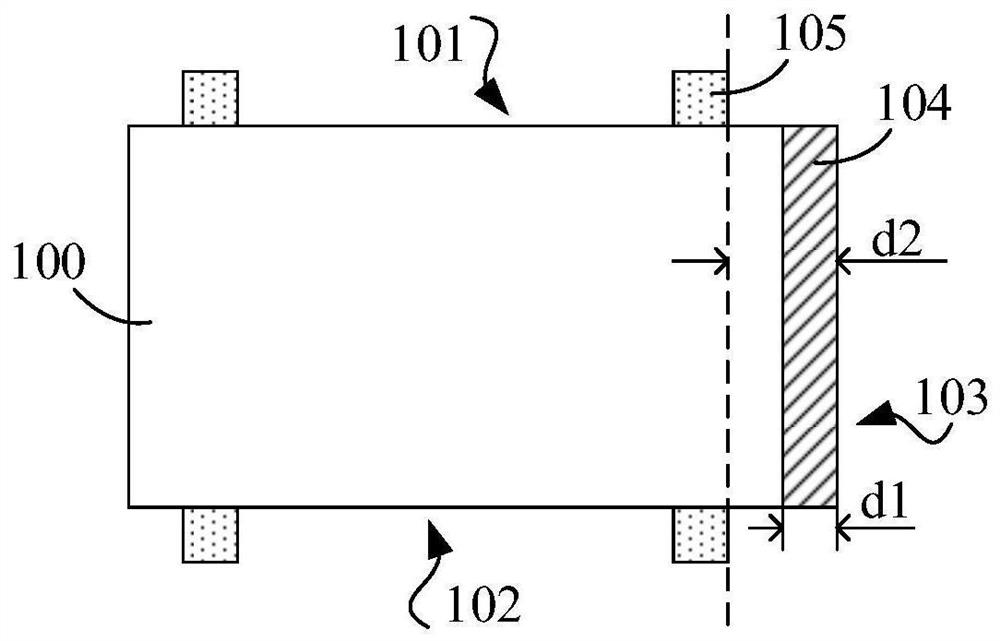

[0022] refer to figure 1 , a structure of a cut passivated battery sheet includes: a battery sheet 100 , a cutting damage area 104 , an electrode 105 and a passivation layer 107 .

[0023] The battery sheet 100 includes a cutting damage area 104, dangling bonds are formed on the cutting surface, and a passivation layer 107 is directly formed on the cutting surface, which will cause the electron-hole recombination center formed by the dangling bonds to be located in the cutting damage area 104, and the electrons and The holes recombine in the cutting damage region 104 , the efficiency of the battery sheet 100 decreases, and the passivation layer 107 does not play a passivation effect.

[0024] In order to solve the above problems, the present invention provides a cell passivation method, which removes the cutting damage area, electrons and holes r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com