Motor, camera module and terminal equipment

A camera module and motor technology, applied in the field of camera modules, terminal equipment, and motors, can solve problems such as difficult implementation and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

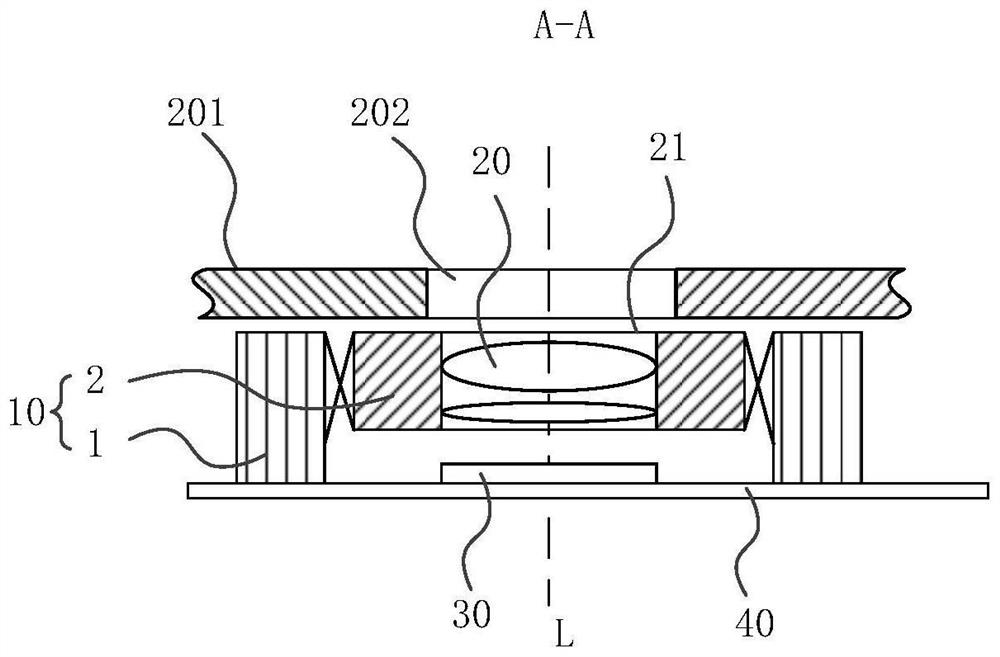

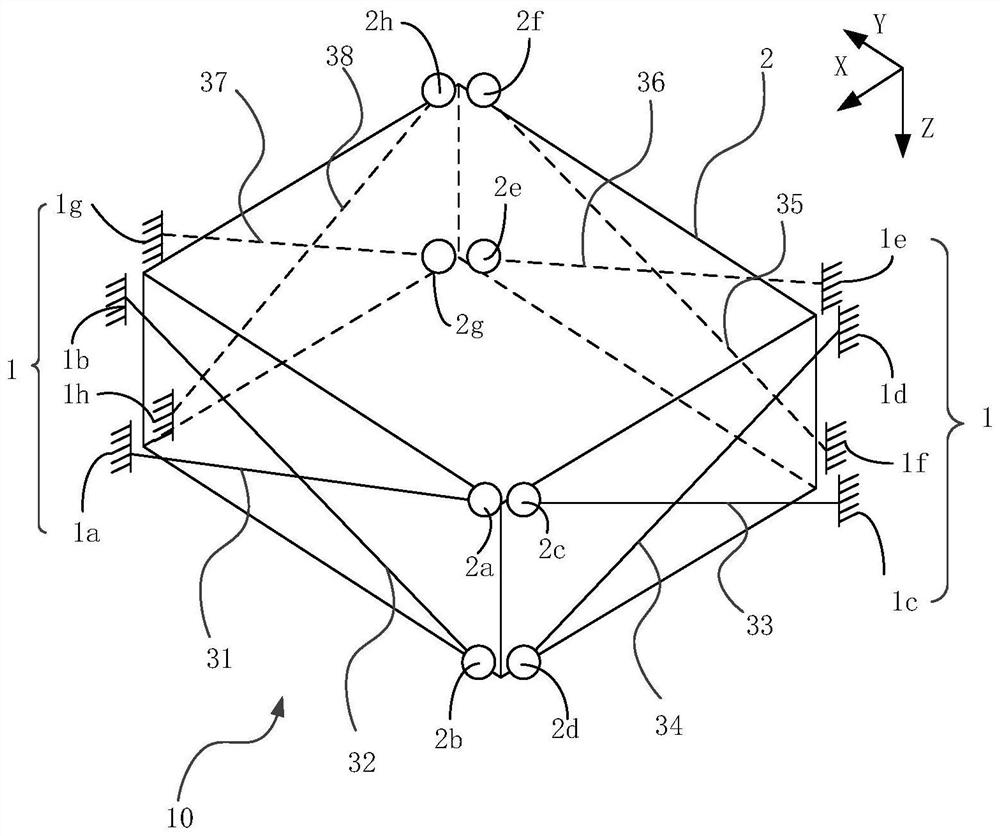

[0094] Before describing the embodiments of the present application, for the convenience of understanding, first explain the terms involved in the embodiments of the present application:

[0095] Shape memory alloy wire: An actuation wire formed of a material that has a shape memory effect through thermoelasticity and martensitic transformation and its inversion. The SMA actuation wire can undergo a phase change when the temperature changes, whereby the stress state also changes. At low temperature, the SMA actuating wire is in the martensite phase state; when the temperature rises, the SMA actuating wire transforms from the martensite phase to the austenite phase, and deforms and shrinks. Therefore, an electric current can be passed through the SMA actuating wire, and the heating effect of the current can be used to heat up the SMA actuating wire, so as to realize shrinkage deformation of the SMA actuating wire. When no current is passed through the SMA actuating wire, the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com