Sugarcane agricultural and sideline product smashing and juicing equipment

A technology for agricultural and sideline products and sugarcane, which is applied in the field of crushing and juicing equipment for sugarcane agricultural and sideline products, which can solve the problems of low extraction rate of sugarcane liquid, inconvenient removal, and easy scratching of human hands by the crushing knife.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

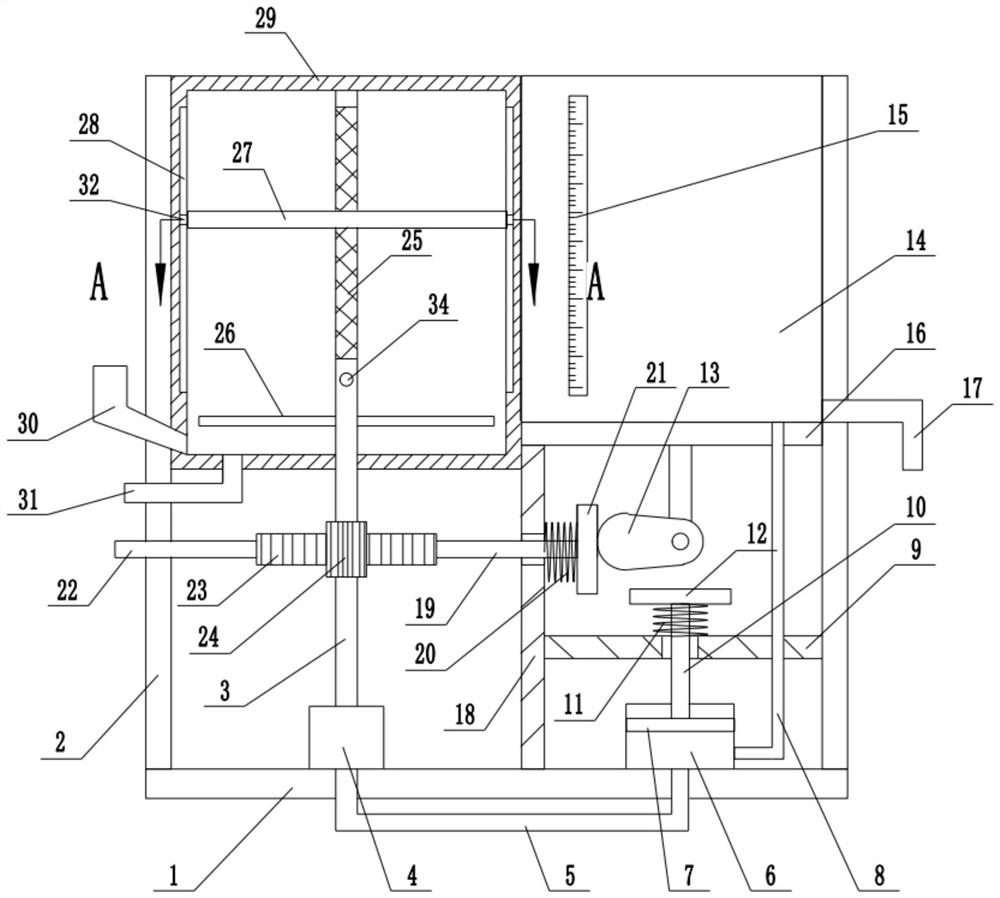

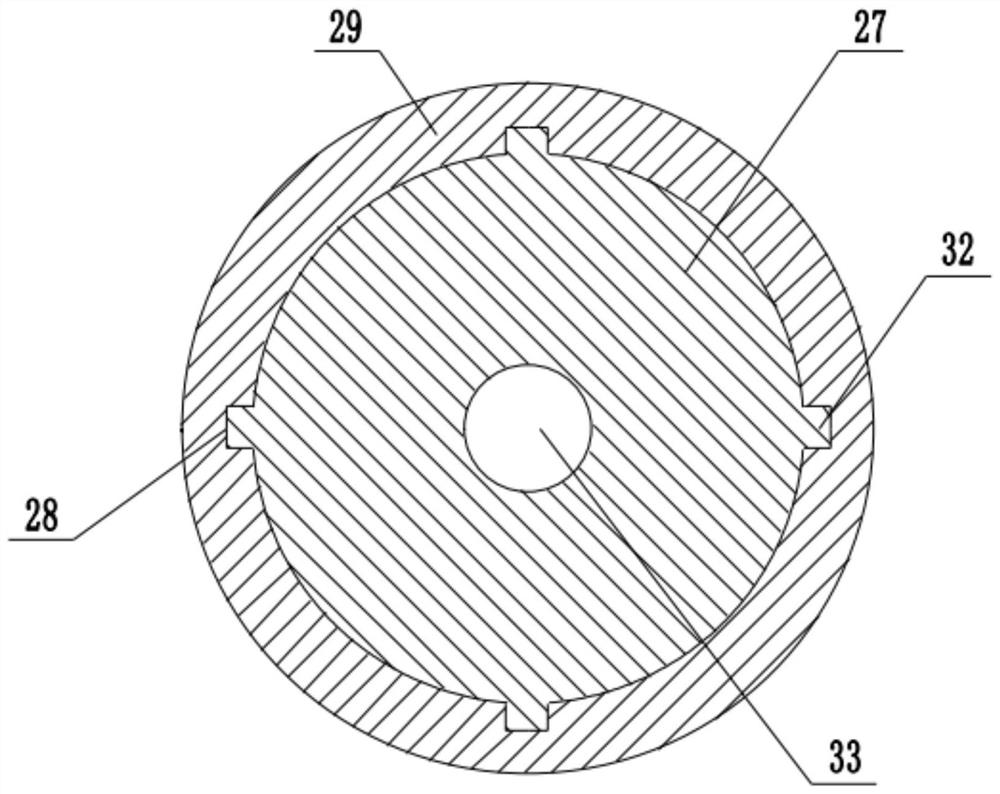

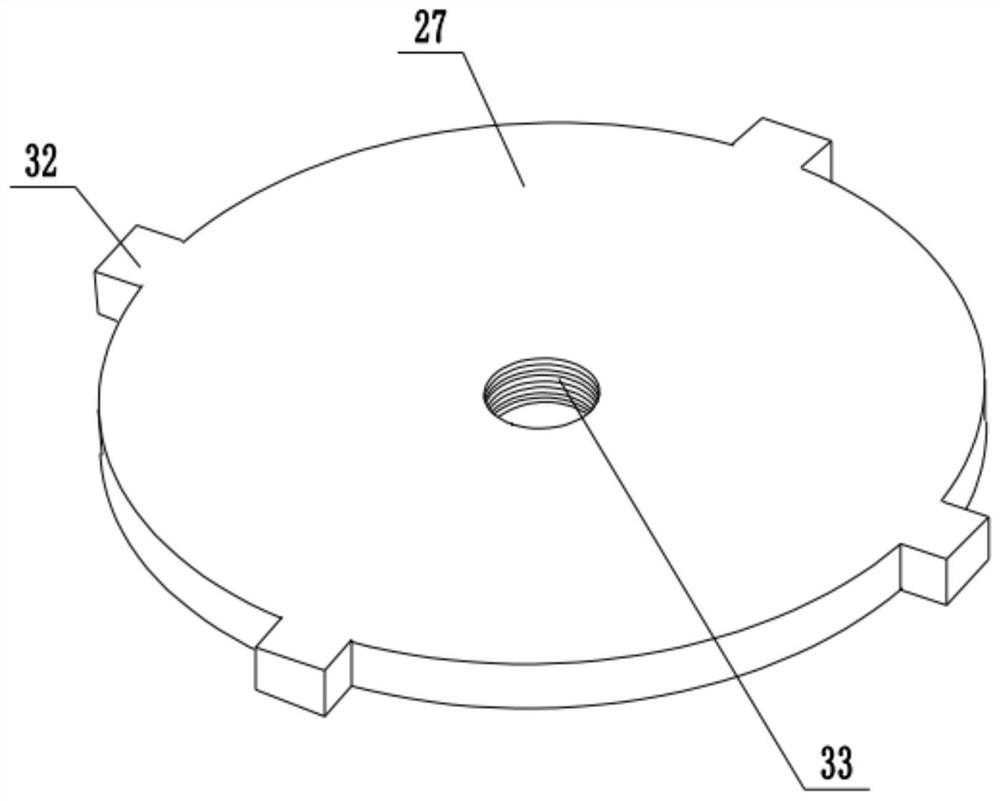

[0031] refer to Figure 1~3 , in an embodiment of the present invention, a sugarcane agricultural and sideline product crushing and juicing equipment includes a fixed base plate 1, and support frames 2 are installed on both sides of the upper end of the fixed base plate 1, and a limit frame 18 is installed in the middle of the upper end of the fixed base plate 1, and the limit frame 18 A truss 16 is installed between the top and the right side support frame 2, and a cam 13 is installed in the middle part of the lower end of the truss 16. The lower end of the cam 13 is in contact with the lower pressing plate 12, and the lower middle part of the lower pressing plate 12 is equipped with a juice-inducing rod 10, and the lower end of the juice-inducing rod 10 is worn A juice suction plate 7 is connected to the baffle plate 9 fixed between the limit frame 18 and the middle part of the right support frame 2, and a juice suction box 6 is installed outside the bottom end of the juice s...

Embodiment 2

[0033] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that, wherein, one-way valves are respectively installed inside the juice suction pipe 5 and the juice outlet pipe 8 to ensure the one-way circulation of the sugarcane juice, After the orderly flow of the juice into the juice storage tank 14 is realized.

[0034] In the present invention, firstly, the sugarcane that needs to be squeezed is introduced into the inside of the juicer box 29 through the feed hopper 30, and then the motor connected to the cam 13 is started to make the cam 13 rotate, thereby ensuring that the protruding parts of the cam 13 contact the upper platen 21 respectively and the lower pressing plate 12, so that the rotating shaft 3 rotates clockwise and counterclockwise, and the juice introduction box 6 works at the same time, and the sugarcane juice inside the juice squeezing box 29 is introduced into the inside of the juice sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com