Explosion-proof storage cabinet for storing industrial chemicals

A chemical and storage cabinet technology, applied in the industrial field, can solve problems such as the increase of ammonium chloride concentration, difficult air circulation, and reduce the probability of accidents, so as to improve the efficiency of cleaning and increase the passing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

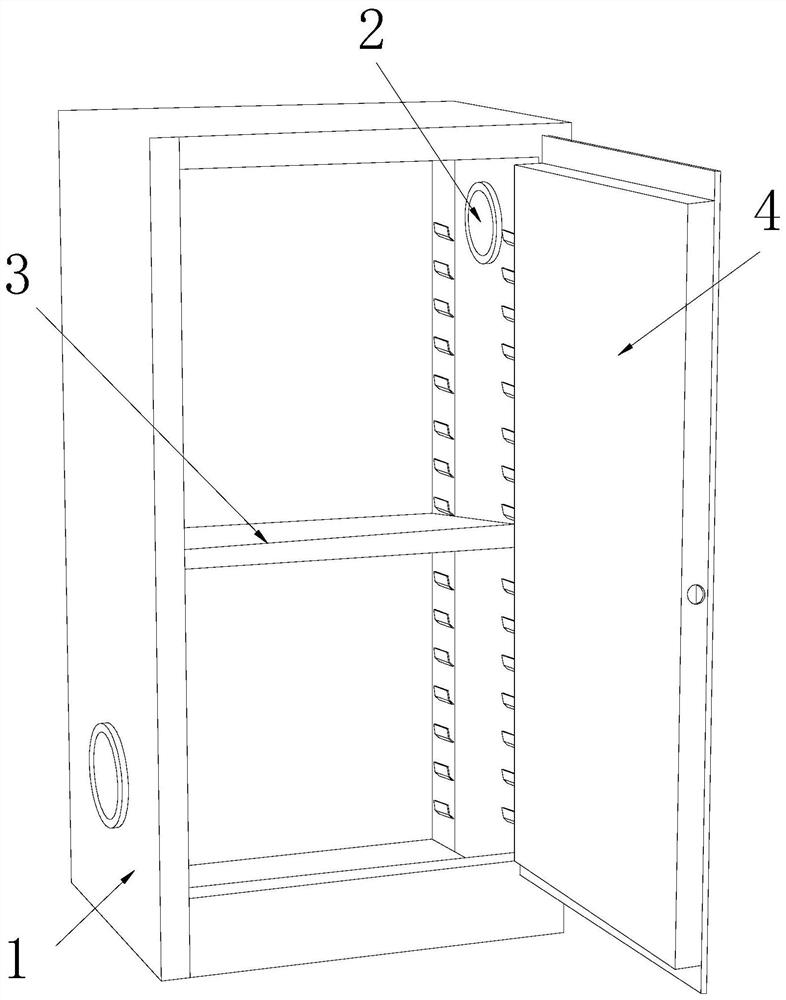

[0024] as attached figure 1 to attach Figure 5 Shown:

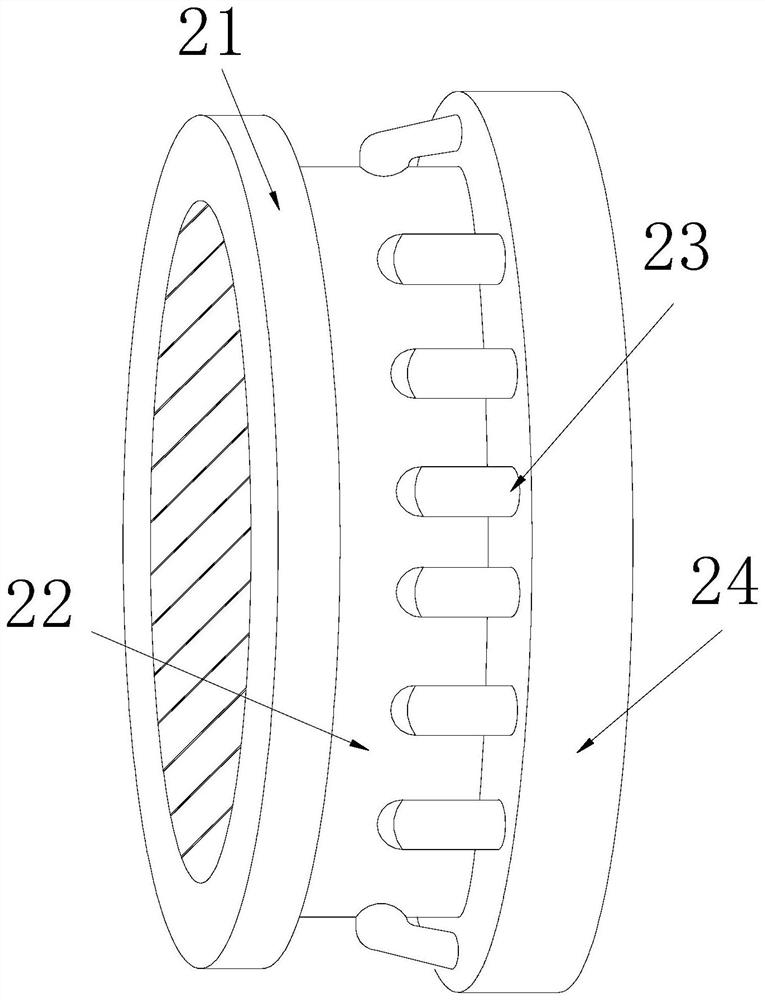

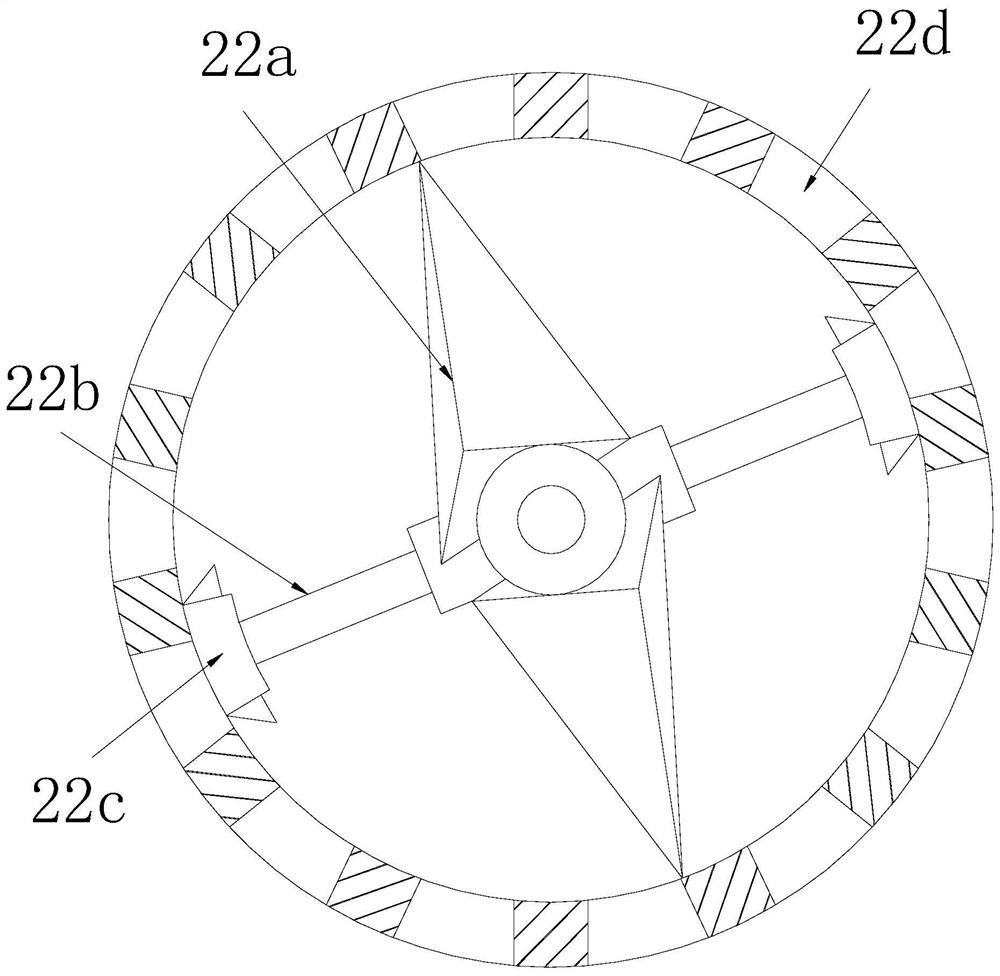

[0025] The invention provides a storage cabinet for storing explosion-proof industrial chemicals, the structure of which includes a cabinet body 1, a vent 2, a storage board 3, and a cabinet door 4. The outer side of the cabinet body 1 is embedded and connected to the outer side of the vent 2. The outer side of the storage board 3 is movably engaged with the inner side of the cabinet body 1, and the cabinet door 4 is hingedly connected to the front of the right end of the cabinet body 1. The vent 2 includes an inner snap ring 21, a passage layer 22, an outlet pipe 23, and an outer buckle ring 24 , the rear side of the inner snap ring 21 is attached to the inner side of the cabinet body 1, one end of the passing layer 22 is welded to the right side of the inner snap ring 21, and the other end is welded to the left side of the outer snap ring 24, and the outlet The tube 23 is connected between the outer side of the passi...

Embodiment 2

[0032] as attached Figure 6 to attach Figure 7 Shown:

[0033] Wherein, the layer wall 22d includes a ring body d11, a one-way block d2, a connecting rod d3, and a through hole d4. The inner shaft is connected, the connecting rod d3 is connected to the middle part of the one-way block d2, and the through hole d4 is embedded in the ring body d11. , the number of the one-way blocks d2 is four, and they are symmetrically distributed left and right, and are distributed in double layers, so that the crystals can pass downwards, but cannot pass upwards, preventing the extruded block c1 from falling backwards.

[0034] Wherein, the one-way block d2 includes an inclined layer d21, a forward groove d22, a support rod d23, and a rotating shaft d4. The upper end is embedded and connected, the support rod d23 is connected between the upper side of the rotating shaft d4 and the lower side of the upper end of the inclined layer d21, the rotating shaft d4 is embedded and connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com