Chemical instrument cleaning device

A technology for chemical instruments and cleaning devices, which is applied to chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc. It can solve problems such as difficult drying, manual water injection, and unsafe cleaning methods, so as to avoid contamination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

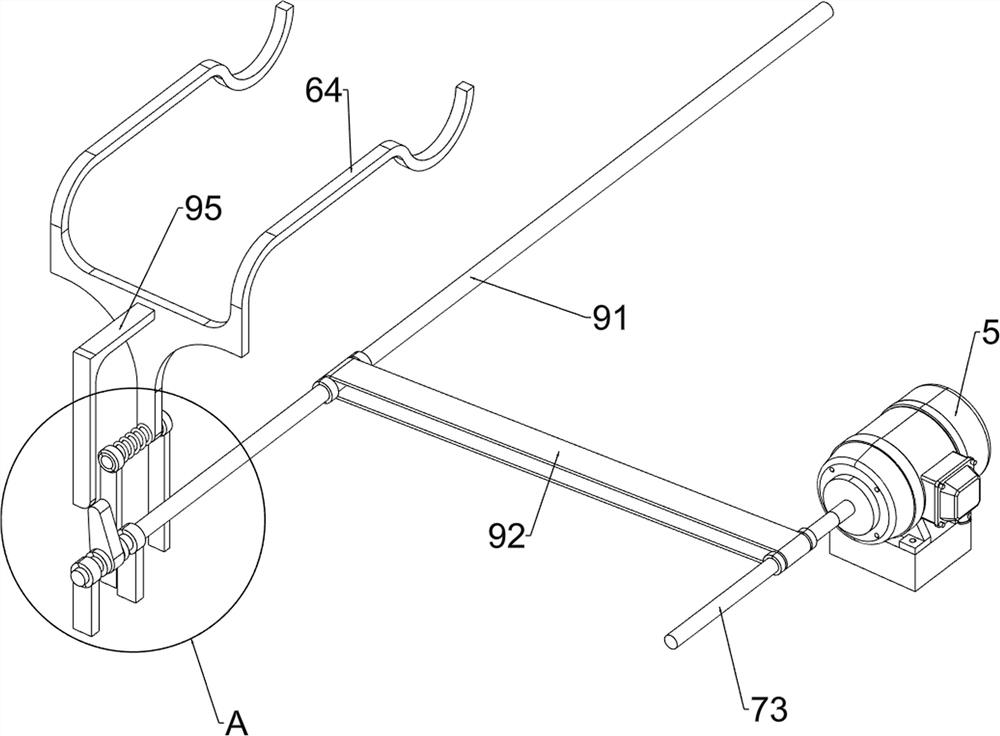

[0027] A chemical instrument cleaning device, such as figure 1 As shown, it includes workbench 1, fixed support 2, cleaning box 3, filter screen 4, motor 5, fixed mechanism 6 and material brushing mechanism 7, and the front and rear sides on the workbench 1 are all left and right symmetrically provided with fixed support 2, four A cleaning box 3 is arranged between the tops of the two fixed brackets, the top of the cleaning box 3 is provided with a filter screen 4, the middle part of the front side of the workbench 1 is equipped with a motor 5, and the left and right sides of the upper rear part of the workbench 1 are provided with a fixing mechanism 6. A material brushing mechanism 7 is provided on the left and right sides of the upper front part of the platform 1, and the material brushing mechanism 7 is connected with the motor 5.

[0028] When people need to clean the chemical instruments after the chemical experiment, this chemical instrument cleaning device can be used. ...

Embodiment 2

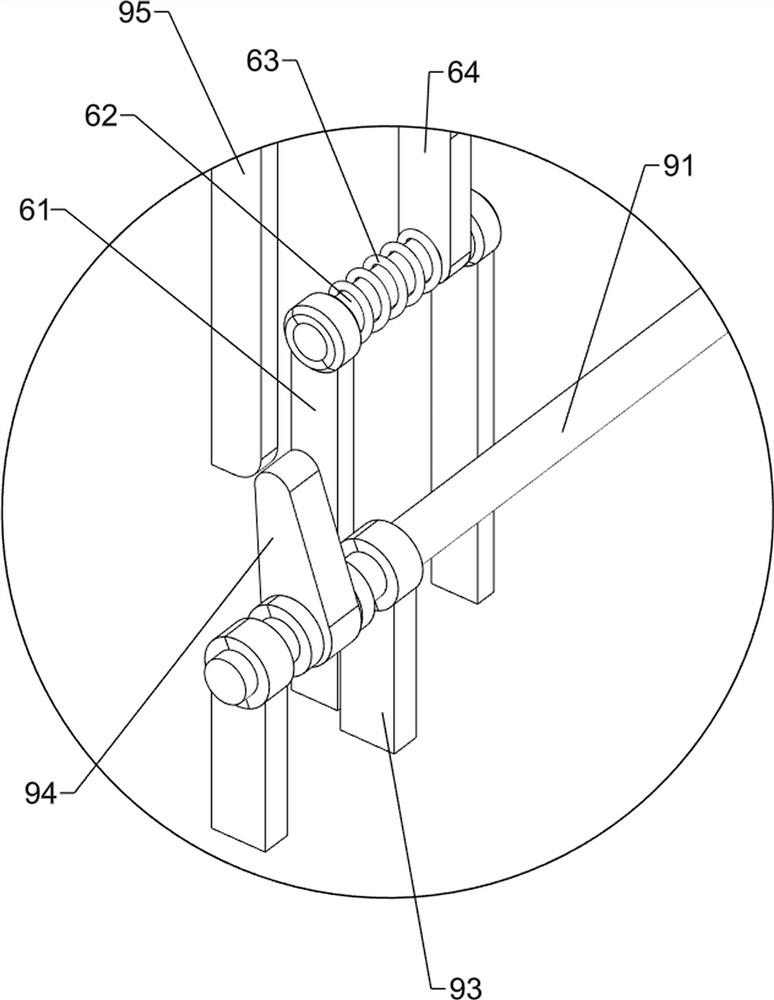

[0030] On the basis of Example 1, such as figure 2 and image 3 As shown, the fixing mechanism 6 includes a first bearing column 61, a first rotating shaft 62, a torsion spring 63 and a support frame 64, and two first bearing columns 61 are arranged on the left and right sides of the upper rear part of the workbench 1, and the left and right sides A first rotating shaft 62 is rotationally connected between the upper parts of the two first bearing columns 61, and a support frame 64 is arranged symmetrically on the inner side of the two first rotating shafts 62, and a torsion spring 63 is wound around the middle of the two first rotating shafts 62, The inner ends of the two torsion springs 63 are connected to the adjacent support frame 64 , and the outer ends of the two torsion springs 63 are connected to the first bearing column 61 on the outside.

[0031] People put the two chemical instruments to be cleaned into a small amount of water and place them flat on the top of the ...

Embodiment 3

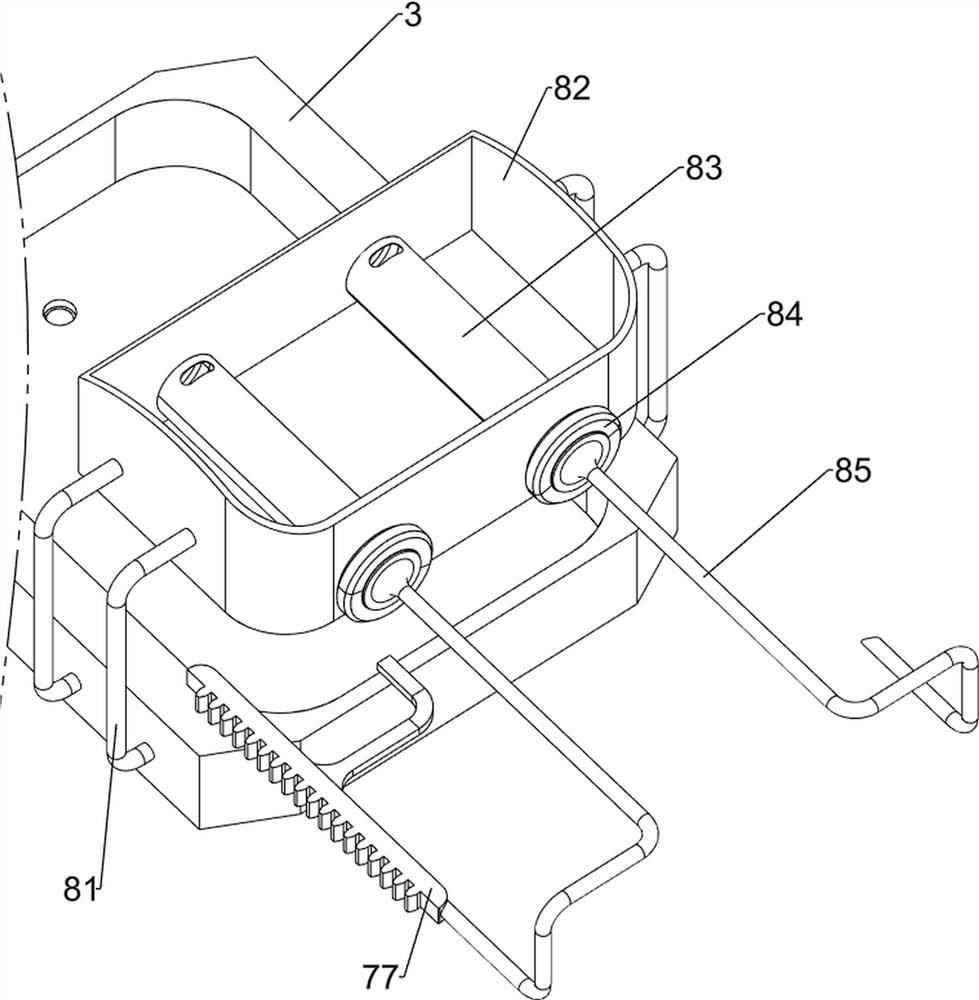

[0035] On the basis of Example 2, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Shown, also comprise water spraying mechanism 8, cleaning box 3 upper front portion is provided with water spraying mechanism 8, and water spraying mechanism 8 includes fixed rod 81, water tank 82, pressure water pipe 83, push plate 84, connecting rod 85 and outlet Water pipe 86, cleaning box 3 front left and right sides walls are all provided with two fixed rods 81, are provided with water tank 82 between four fixed rods 81 tops, are connected with two pressure water pipes 83 between the front and rear sides of water tank 82 interiors, two The front ends of each rack 77 are provided with connecting rods 85, and the rear ends of the two connecting rods 85 are provided with push plates 84. Both ends are provided with outlet pipes 86.

[0036] People put the tail end of the water outlet pipe 86 into the chemical instrument, and pour the clear water for cleaning the chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com