Impurity removal device for cheeses

A technology of cheese and air is applied in the field of impurity removal devices for cheese, which can solve the problems affecting the quality and consistency of the package of the cheese and the disorder of the end of the cheese, and achieve the effect of reliable removal and prevention of secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose and advantages of the present application clearer, the present application will be specifically described below in conjunction with the embodiments. It should be understood that the following words are only used to describe one or several specific implementation modes of the application, and do not strictly limit the scope of protection specifically requested by the application. The features in the examples can be combined with each other.

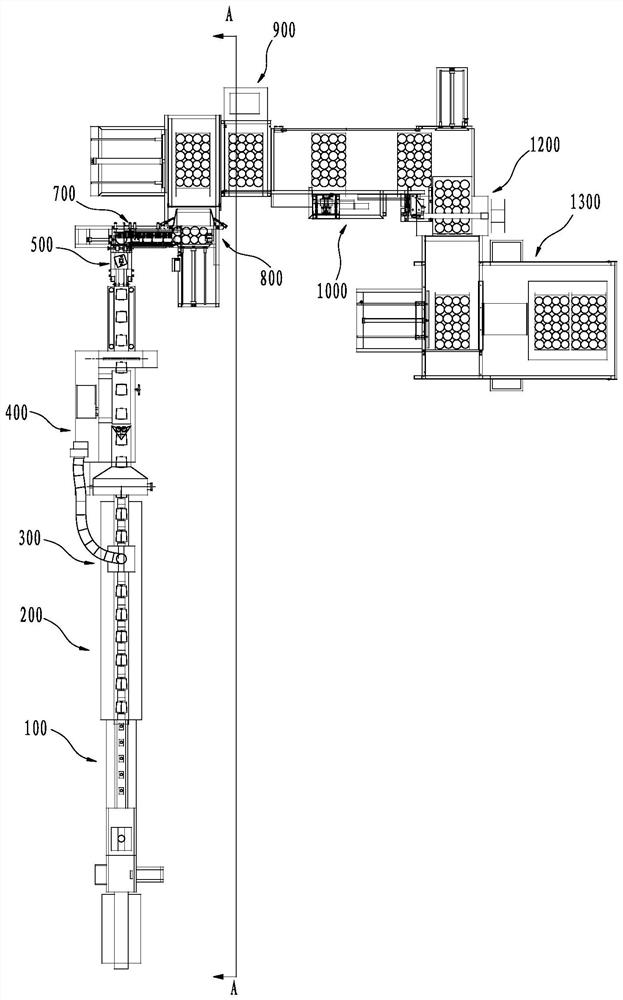

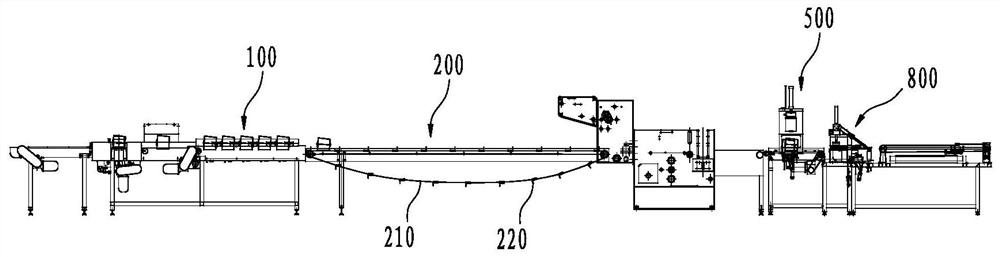

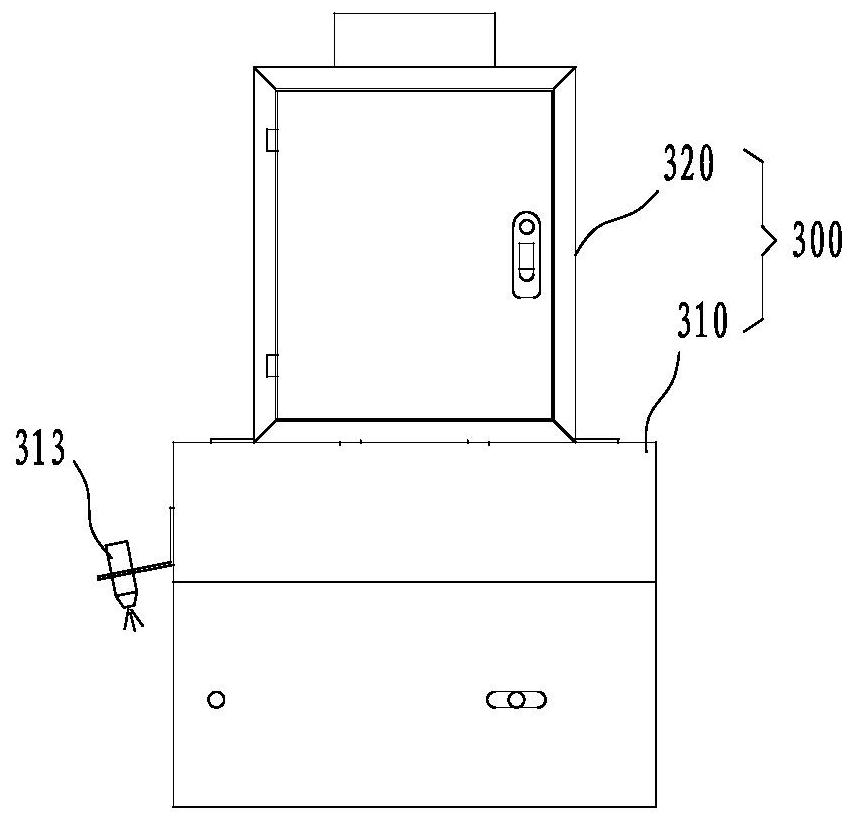

[0055] refer to Figure 1 to Figure 23 , this embodiment provides an automatic bagging and packaging equipment for cheeses, which aims to solve the technical problem that there is currently a lack of equipment for continuous automatic packaging of cheeses, resulting in low production efficiency.

[0056] The specific implementation scheme adopted in this embodiment is that the equipment includes a conveying line 200 for conveying the cheeses at intervals, a discharge unit 700 for arranging the cheeses u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com