Submersible pump machine facilitating control of motor power supply system

A technology of motor power supply and pump machine, which is applied to the components of the pumping device for elastic fluid, machine/engine, pump, etc. effect of time, faster air flow, faster evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 To attach Figure 5 Shown:

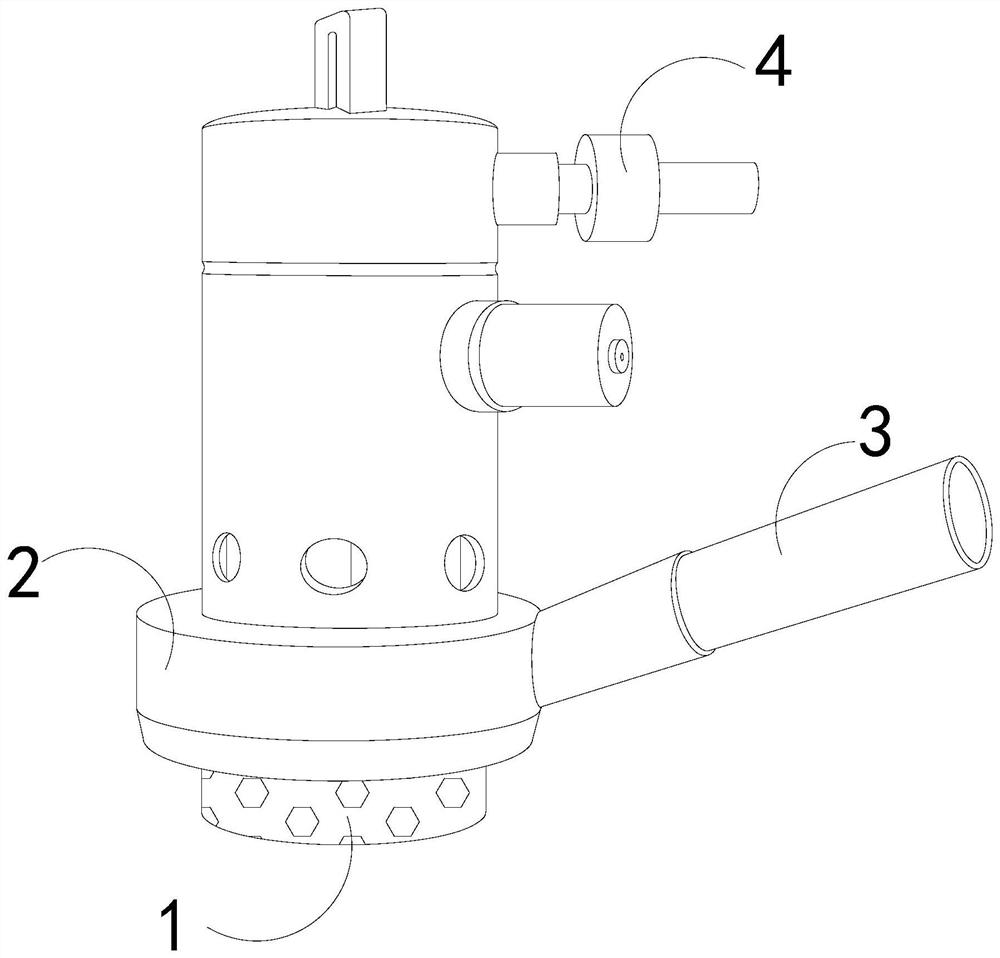

[0028] The present invention provides a submersible pump that is convenient to control the motor power supply system. Its structure includes a base 1, a pump body 2, a water inlet pipe 3, and a water outlet pipe 4. The pump body 2 is vertically welded on the top of the base 1, and the water inlet pipe 3 It is obliquely installed on the right side of the pump body 2, and the outlet pipe 4 is horizontally fixed on the right side of the top of the pump body 2.

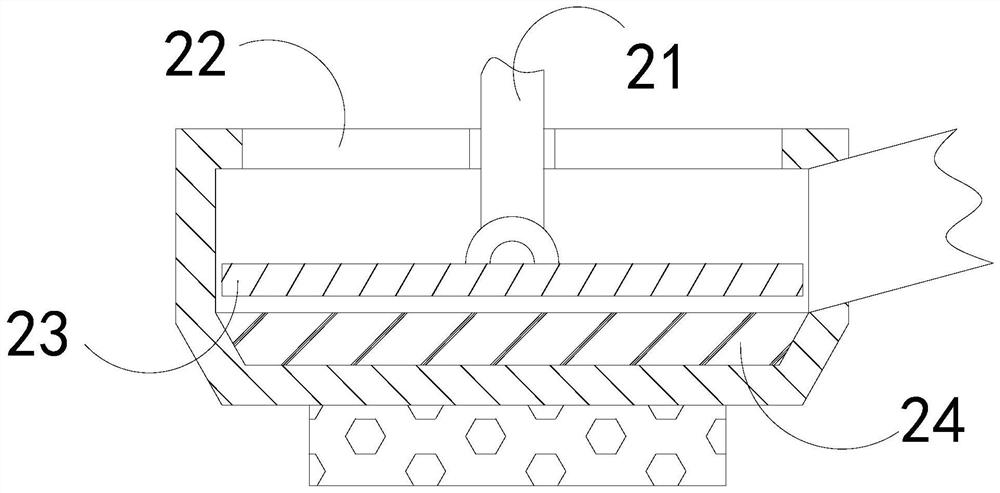

[0029] The pump body 2 is provided with a bearing 21, a water outlet 22, a blade 23, and a pushing mechanism 24. The bearing 21 runs through the center of the top of the pump body 2, and the water outlet 22 runs through the top surface of the pump body 2 and is located on both sides of the bearing 21. On the side, the vane 23 is fixed on the bottom of the bearing 21 , and the pushing mechanism 24 is sleeved on the inner bottom of the pump body 2 .

[0030] Wherei...

Embodiment 2

[0036] as attached Image 6 To attach Figure 8 Shown:

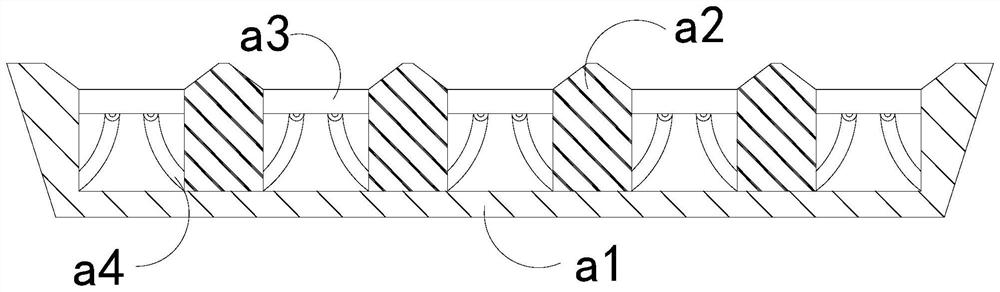

[0037] Wherein, the support block a2 is provided with a swing plate n1, a clamping block n2, an inner cavity n3, and a support bar n4, the swing plate n1 is located on both sides of the support block a2, and the clamp n2 is embedded and fixed on the inner surface of the swing plate n1 , the inner cavity n3 is located inside the support block a2, the support bar n4 is connected to the top of the swing plate n1, and the support bar n4 is made of rubber material with elasticity, which is conducive to pushing the swing plate n1 to both sides and speeding up the swing plate n1 is in active cooperation with the laminating plate s4, and the inner side of the oscillating plate n1 has an uneven surface, which is conducive to increasing the contact area with the gas in the inner cavity n3 and accelerating the diffusion of the gas in the inner cavity n3.

[0038]Wherein, the support bar n4 is provided with a swing rod r1, a reset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com