A spray tower for feed protein peptide

A feed protein and spray tower technology, which is applied in the field of feed protein peptide spray tower, can solve problems such as spray head failure and protein powder accumulation, and achieve the effect of reducing adhesion, reducing adhesion, and improving output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

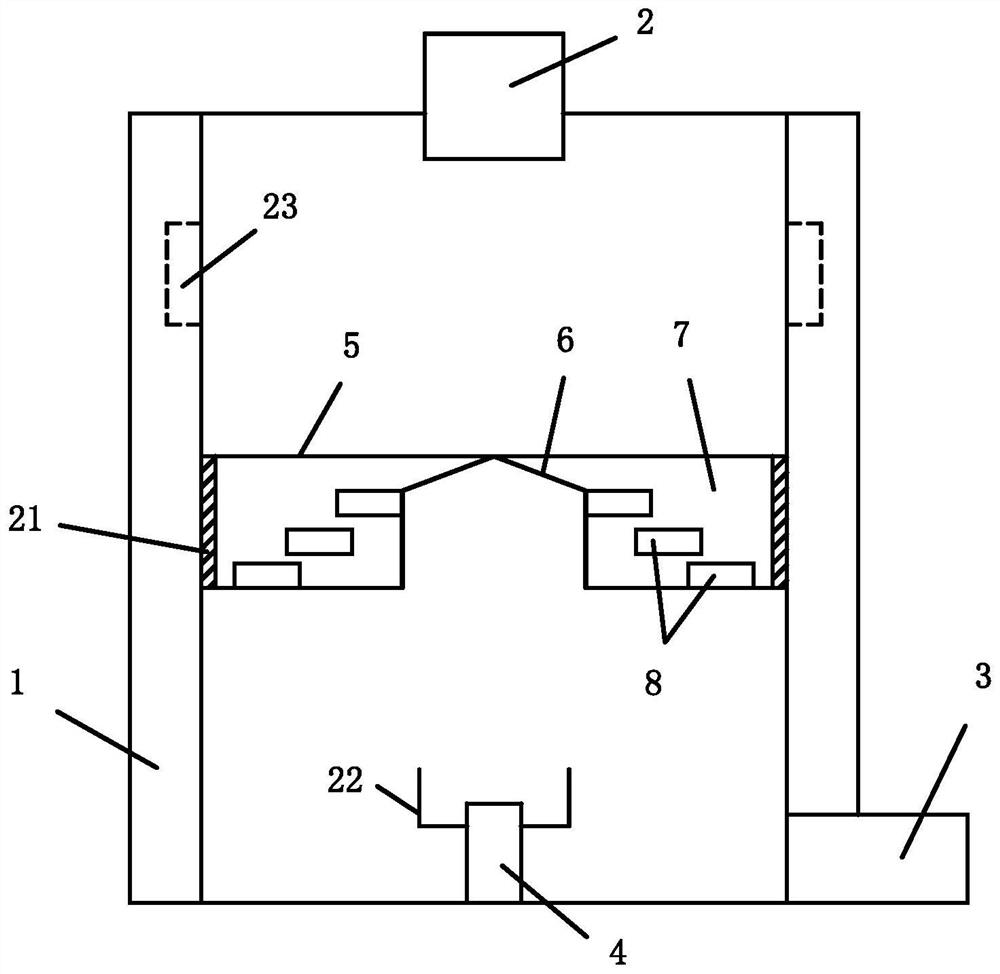

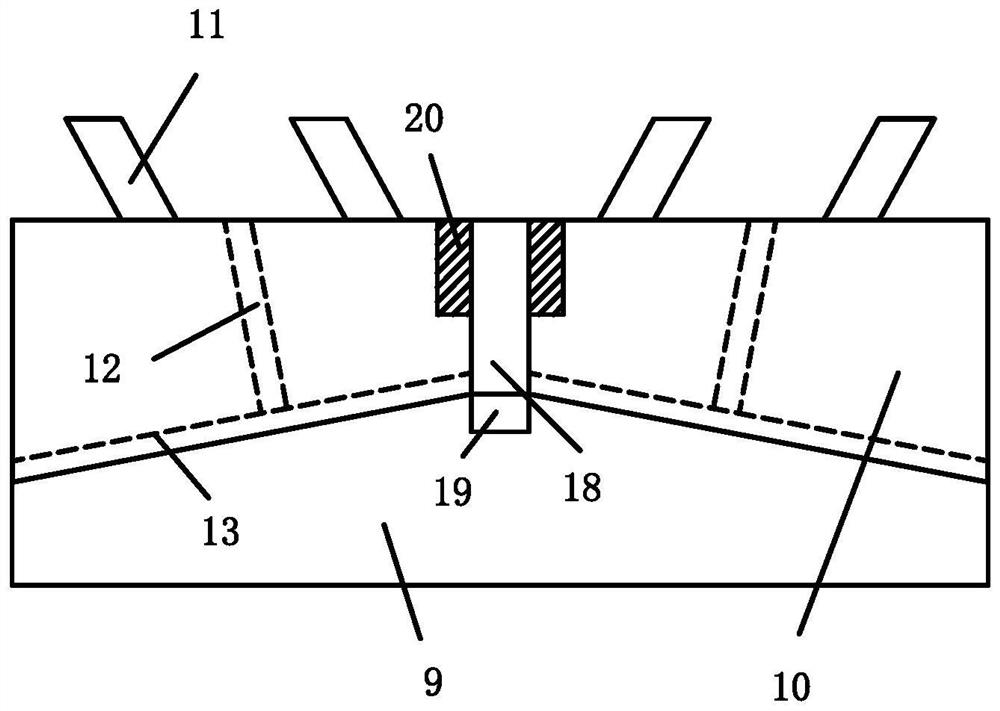

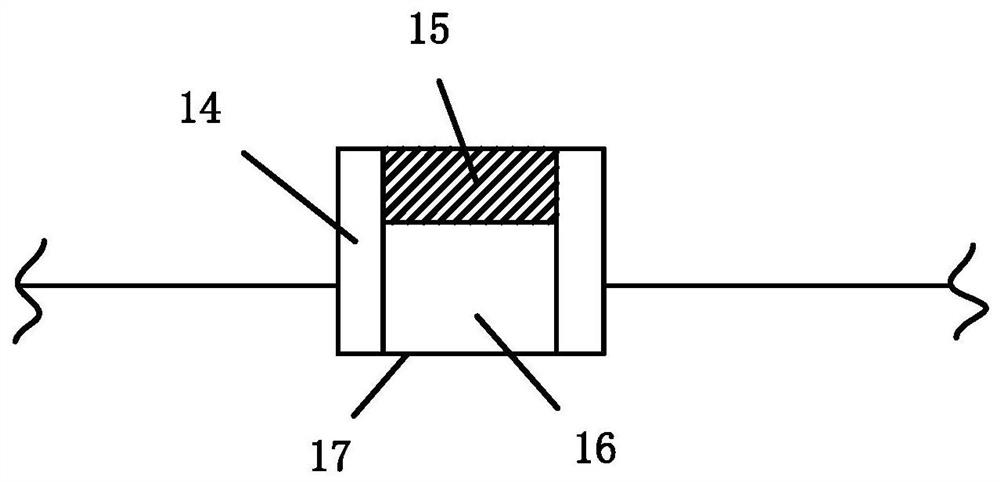

[0014] refer to Figure 1-3 A specific embodiment of the present invention includes a tank body 1, a hot air intake pipe 2 is connected to the top of the tank body 1, a protein collection pipe 3 is connected to one side of the bottom of the tank body 1, and a material nozzle is installed vertically upward at the center of the bottom of the tank body 1 4. A material drying tray 5 is installed in the center of the tank body 1, and a conical baffle 6 is installed in the center of the top of the material drying tray 5. A metal mesh 7 is arranged on the outside of the conical baffle 6, and several metal meshes are arranged inside the metal mesh 7. Annular groove 8, the height of different annular grooves 8 gradually decreases from the inside to the outside, the lower grinding sheet 9 is fixed in the annular groove 8, the top center of the lower grinding sheet 9 is equipped with a connecting shaft 18 through a shaft sleeve 19, and a connecting shaft 18 is installed with The upper gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com