Metal oxide arrester overvoltage detection method and system based on three-stage voltage division

A technology of three-stage voltage division and detection method, applied in the direction of measuring current/voltage, instruments, measuring devices, etc., can solve the problems of difficulty in determining the latent fault of the arrester, high sampling frequency and frequency response, and steep lightning overvoltage wave head. , to achieve the effect of good shock and steady-state response characteristics, short response time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the examples.

[0059] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The materials or equipment used are not indicated by the manufacturer, and they are all conventional products that can be obtained through purchase.

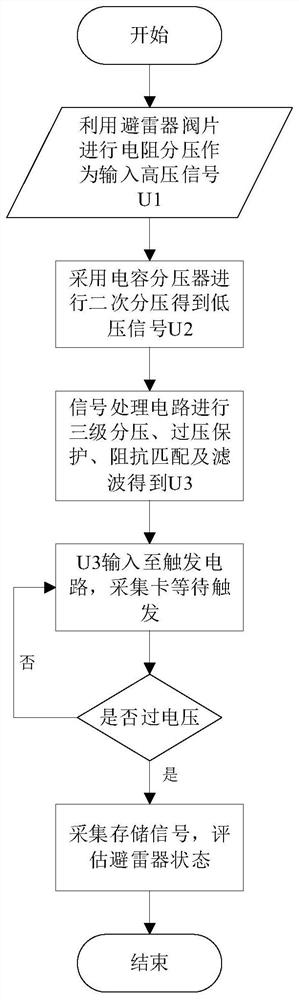

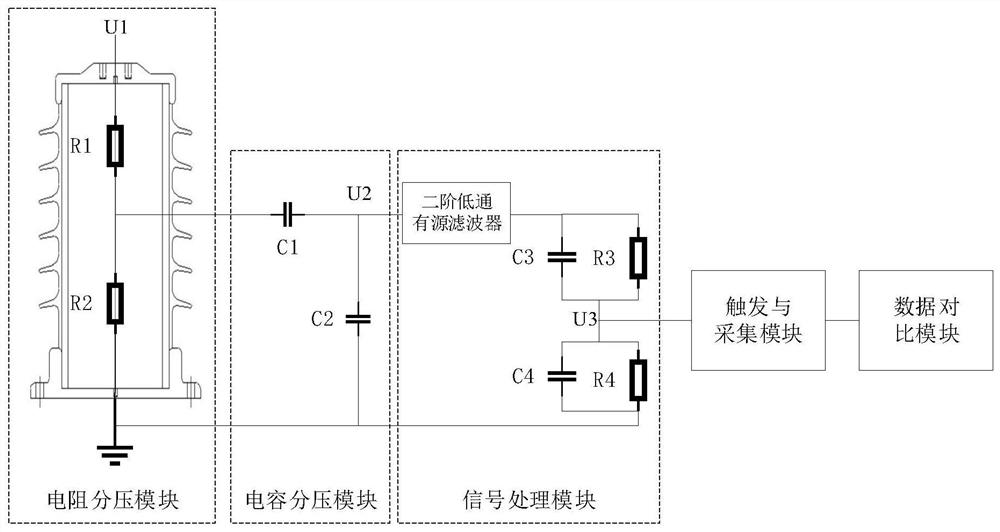

[0060] see figure 1 , a kind of metal oxide arrester overvoltage detection method based on three-stage voltage division of the present invention, specifically comprises the following steps:

[0061] Step 1, the detection system is connected in parallel to both sides of the last valve plate at the grounding end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com