Optimization method of energy feedback device of energy feedback suspension

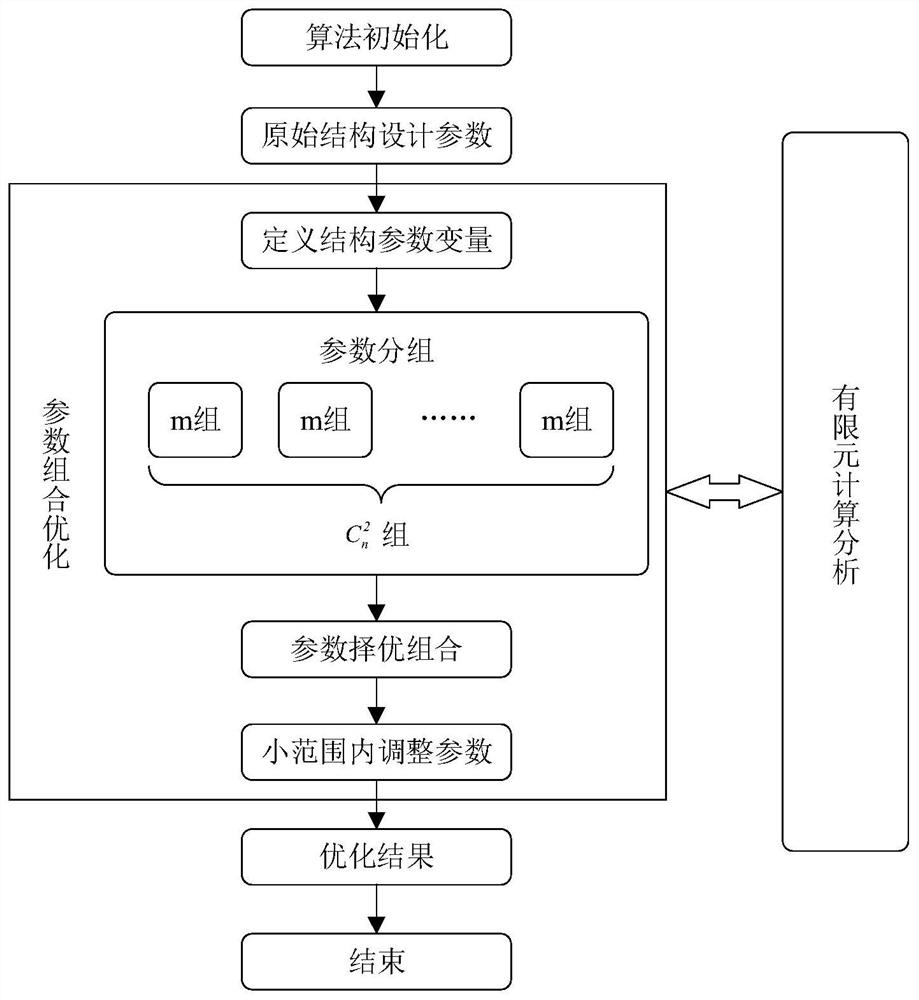

An optimization method and energy-feeding technology, applied in design optimization/simulation, constraint-based CAD, special data processing applications, etc., can solve problems such as difficult optimization, large amount of calculation, complex parameter optimization, etc. Optimize the effect and simplify the effect of the optimization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

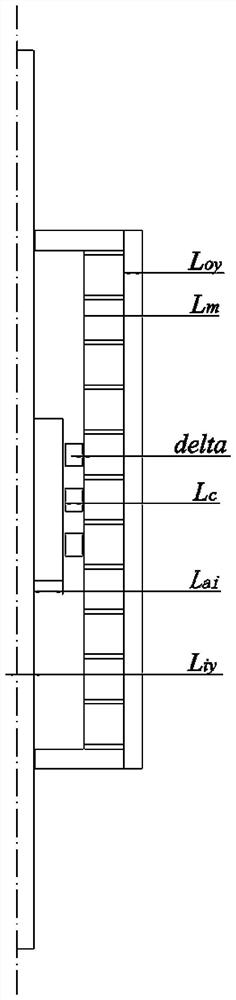

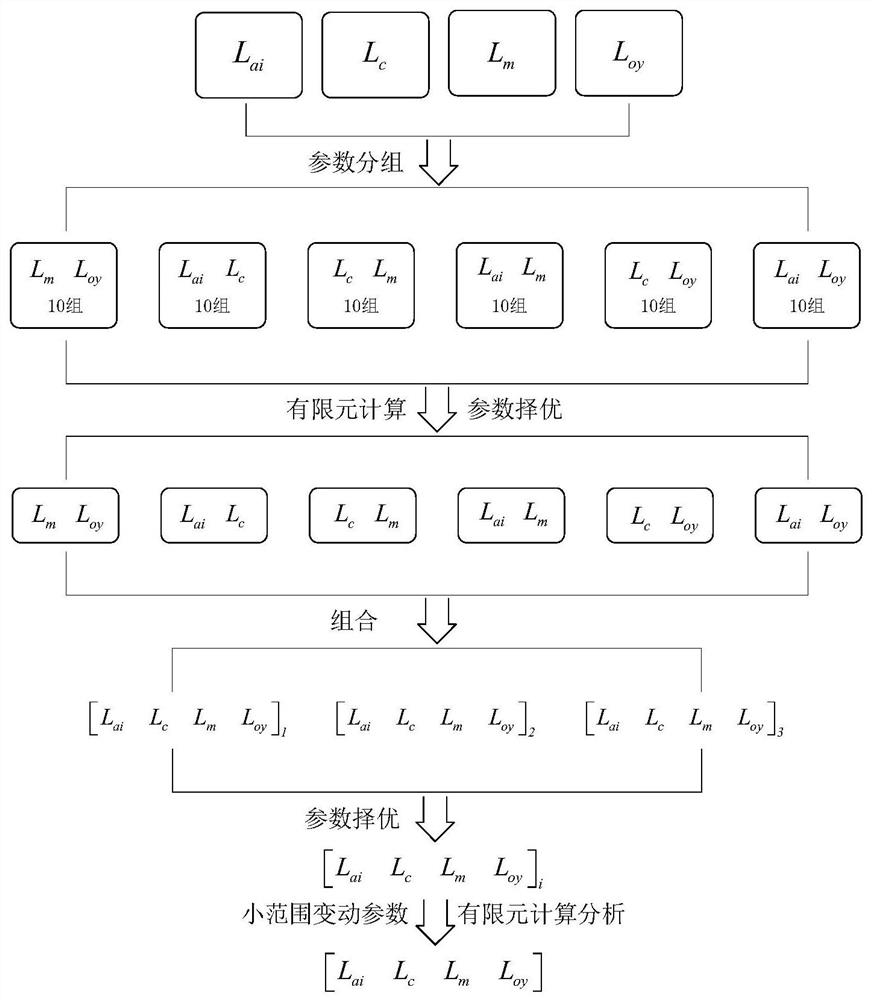

[0016] Taking Langxing 2017 manual comfort version as the research object, its front suspension is McPherson independent suspension, and an electromagnetic linear actuation-energy feeding device (ELA-ERD) is installed on the basis of it. According to the spring inner diameter of 98mm, it is determined The outer dimension of the feeder motor is 90mm, and then the internal structure is designed, and the preliminary design parameters are shown in the table.

[0017] Table 1 ELA-ERD Outline Dimensions

[0018]

[0019] The internal structure size is designed under the constraints of the external size. In order to maximize the efficiency of the feeder motor, the structural parameters are determined for the original design of the motor. The height of each part is determined according to the profile height and the suspension stroke, and they are all fixed values. Therefore, the radial dimensions of each internal structure are optimized to obtain higher motor feed power and motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com