Remediation method for contaminated site soil treatment

A technology of polluted soil and remediation method, which is applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of secondary soil pollution, etc., and achieves large processing capacity, wide application range, and improved utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

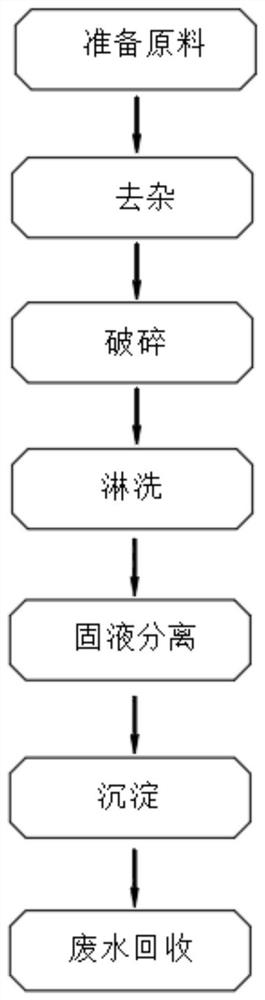

[0029] refer to figure 1 , a restoration method for soil treatment of contaminated sites, comprising the following steps:

[0030] S1: Prepare raw materials, polluted soil, leaching agent, flocculant, coagulant aid and alkali solution;

[0031] S2: Remove impurities, remove the garbage in the polluted soil;

[0032] S3: crushing, the contaminated soil after removal of impurities is crushed and pretreated by a soil crusher;

[0033] S4: Leaching. First, use water to perform heterotopic leaching on the contaminated soil, and then add leaching agent to perform ectopic rinsing on the soil to obtain a mixed solution;

[0034] S5: Solid-liquid separation, solid-liquid separation of the mixed solution, backfilling the soil qualified for leaching, and retaining the cleaning solution for subsequent processing;

[0035] S6: Precipitation, put the cleaning solution into the sedimentation tank for precipitation to obtain heavy metals and waste water;

[0036] S7: waste water recovery,...

Embodiment 2

[0041] refer to figure 1 , a restoration method for soil treatment of contaminated sites, comprising the following steps:

[0042] S1: Prepare raw materials, polluted soil, leaching agent, flocculant, coagulant aid and alkali solution;

[0043] S2: Remove impurities, remove the garbage in the polluted soil;

[0044] S3: crushing, the contaminated soil after removal of impurities is crushed and pretreated by a soil crusher;

[0045] S4: Leaching. First, use water to perform heterotopic leaching on the contaminated soil, and then add leaching agent to perform ectopic rinsing on the soil to obtain a mixed solution;

[0046] S5: Solid-liquid separation, solid-liquid separation of the mixed solution, backfilling the soil qualified for leaching, and retaining the cleaning solution for subsequent processing;

[0047] S6: Precipitation, put the cleaning solution into the sedimentation tank for precipitation to obtain heavy metals and waste water;

[0048] S7: waste water recovery,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com