A heat dissipating device based on one object one code association system

A heat dissipation device, a technology of one object, applied in printing devices, cooling/ventilation/heating transformation, typewriters, etc., can solve the problems of increased service life of components, reduced printing efficiency, poor heat dissipation efficiency and effect, and achieve the goal of preventing water drops Condensation, increased service life, convenient increase or decrease effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

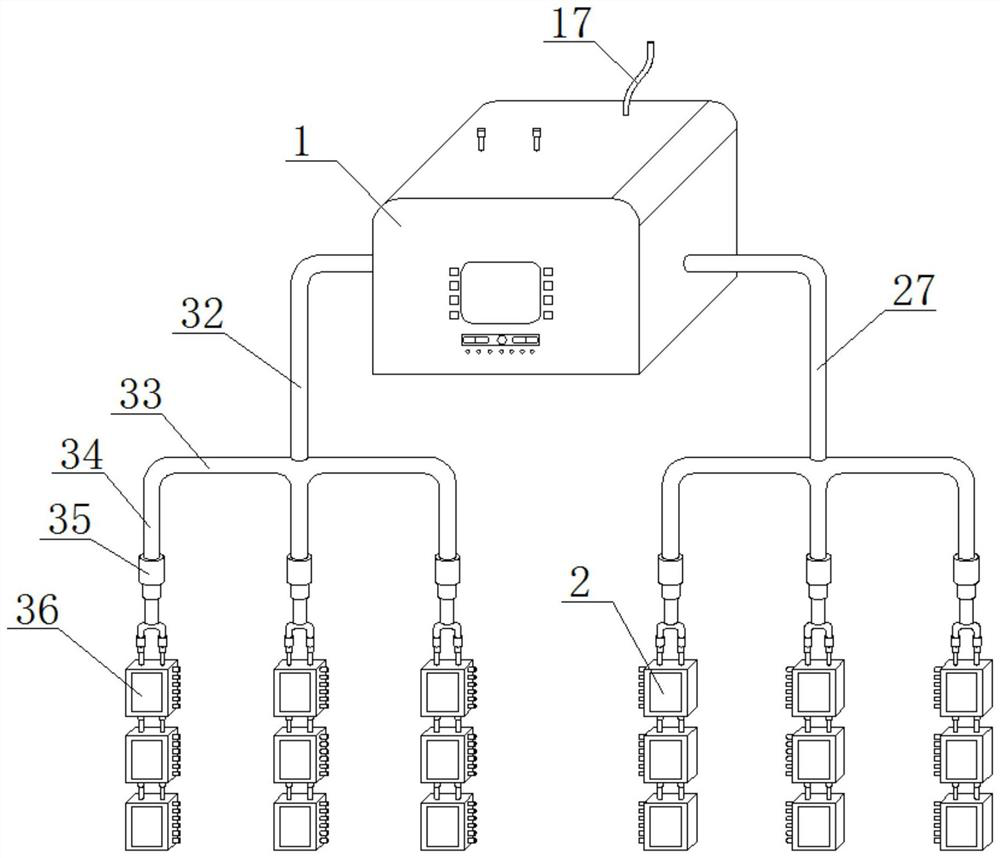

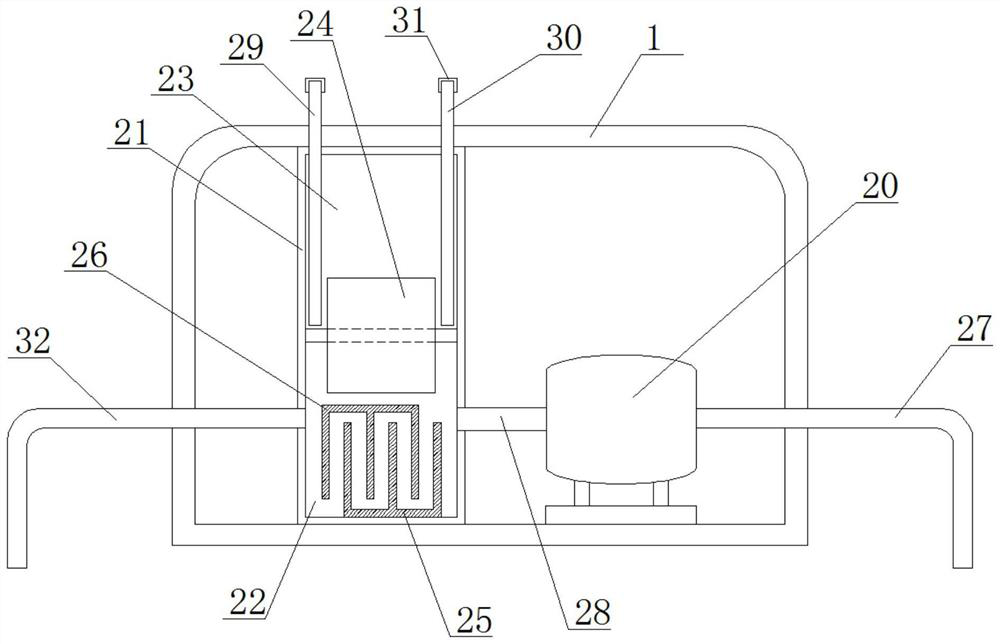

[0027] As a preferred embodiment of the present invention, a power cord 17 is fixedly connected to the top of the housing 1 , and the power cord 17 is electrically connected to the air pump 20 and the semiconductor cooling chip 24 respectively through a power supply circuit.

[0028] As a preferred embodiment of the present invention, the semiconductor refrigerating sheet 24 includes a cold end and a hot end, and the cold end and the hot end are respectively located in the cooling chamber 22 and the water absorption chamber 23. During the heat dissipation process, the heat The water collected in the heat-absorbing chamber 23 can quickly take out the heat by replacing the water in the heat-absorbing chamber 23 , which is highly practical.

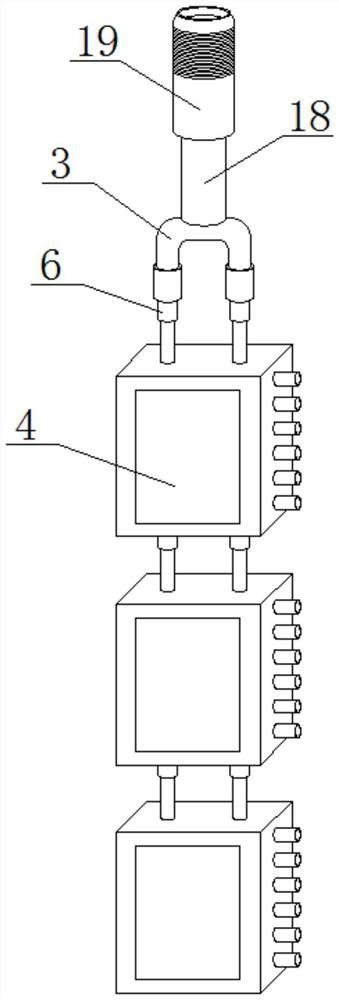

[0029] As a preferred embodiment of the present invention, there are two branch connecting hoses 5 , spherical holes 11 and connecting balls 12 , and when one of the branch connecting hoses 5 is blocked, the whole can still work.

[0030] As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com