Surface mine slope rock mass quality evaluation method

A technology for rock mass quality evaluation and slope, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to achieve objective and accurate classification, achieve objective evaluation results, avoid sudden changes, and eliminate ambiguity

Pending Publication Date: 2021-02-19

NORTHWEST RES INST OF MINING & METALLURGY INST

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For another example, when the uniaxial compressive strength is 249MPa, the score is 12, but when the uniaxial compressive strength is 101MPa, the score is also 12. Therefore, the current method cannot achieve objective and accurate classification

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0102] Evaluation and classification of open-pit slope rock mass quality in Suokuang open-pit copper mine in Xinjiang.

[0103] 1. Determination of Index Score Values

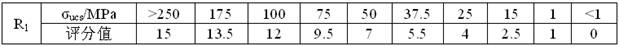

[0104] (1) Rock compressive strength R 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

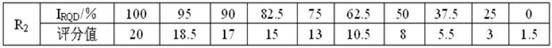

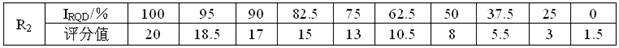

The invention relates to a surface mine slope rock mass quality evaluation method which comprises the following steps of (1) measuring uniaxial compressive strength sigmaucs of slope rock at a pre-evaluated surface mine slope, and determining a score value and a compressive strength index R1, (2) respectively obtaining rock quality IRQD, a joint spacing Jv and a joint condition R4, and determiningrespective score values, a rock quality index R2 and a joint spacing index R3, (3) observing and recording the underground water state, and determining a score value and an underground water state R5, (4) determining the value of a correction parameter R6 of the slope stability in the joint direction according to the included angle between the joint direction and the slope inclination, (5) determining a blasting vibration influence coefficient eta and a rock mass quality score correction parameter R7 of the blasting vibration influence coefficient eta, (6) calculating to obtain a total sloperock mass quality comprehensive score value S, and (7) obtaining the quality grade of the surface slope rock mass according to the comprehensive score value S. The real situation can be objectively and accurately reflected.

Description

technical field [0001] The invention relates to the technical field of open-pit mine slope rock mass, in particular to a method for evaluating the quality of open-pit mine slope rock mass. Background technique [0002] The evaluation method of slope rock mass quality commonly used at home and abroad at this stage is the RMR method, but in this evaluation method, the impact of blasting disturbance on the quality of slope rock mass is not considered. When evaluating the scoring values of the three indicators, joint spacing and joint spacing, the jump scoring method is adopted. Although this method is simple, it will cause a "mutant change" in the score. When the indoor rock uniaxial compressive strength is 251MPa, according to the RMR method, its score is 15; when the uniaxial compressive strength is 249MPa, its score is 12. But in fact, there is no big difference in the compressive strength of the two rocks, but the difference between the two weights is 3 points. For anot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/08G01N3/02G01N33/24

CPCG01N3/08G01N3/02G01N33/24

Inventor 张晨洁赵海军张青草

Owner NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com