Static-error-free automatic feedback high-precision fault inversion method

An automatic feedback, high-precision technology, applied in the improvement of basic electrical components, circuit breaker testing, etc., can solve the problem that the current and voltage injected into the detection equipment cannot be continuously adjusted, and achieve the effect of not being continuously adjustable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

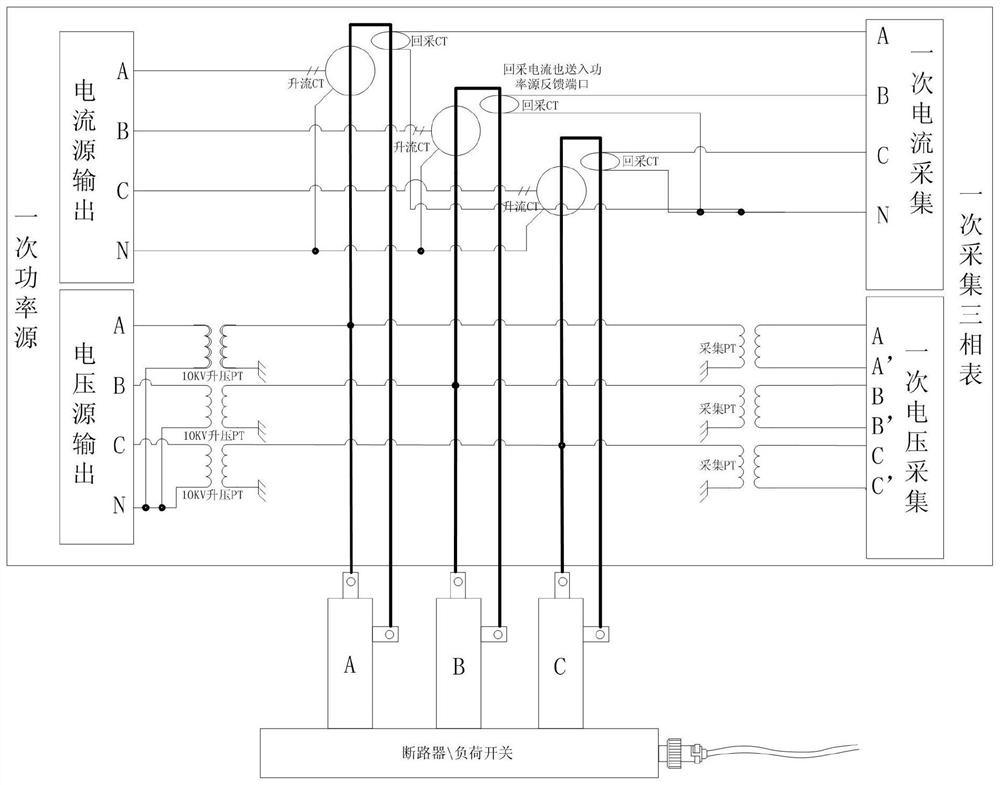

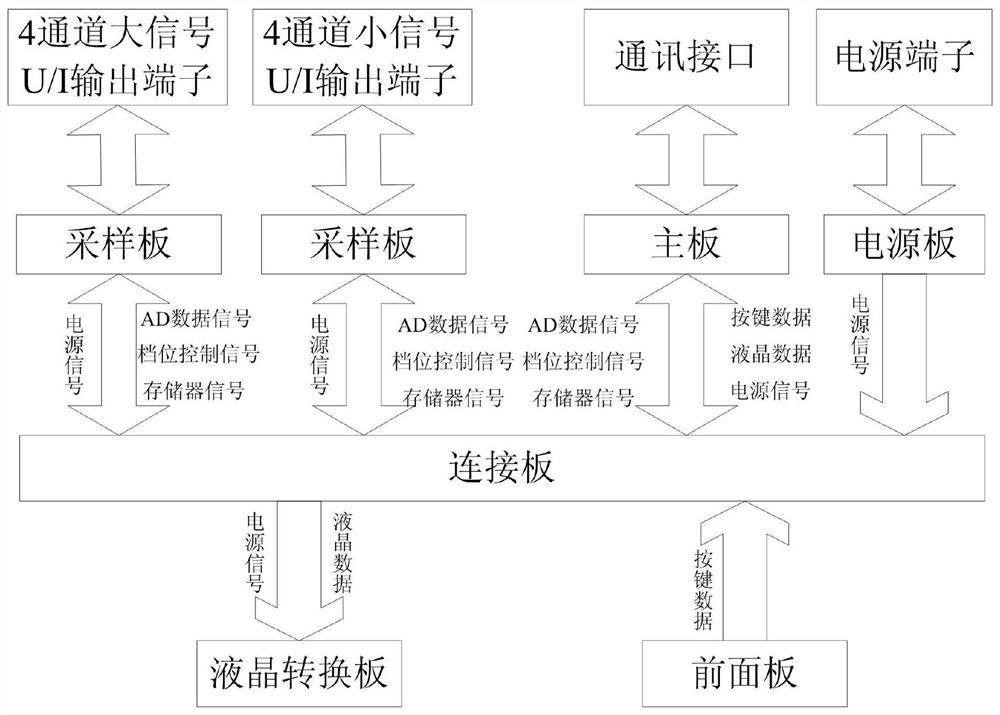

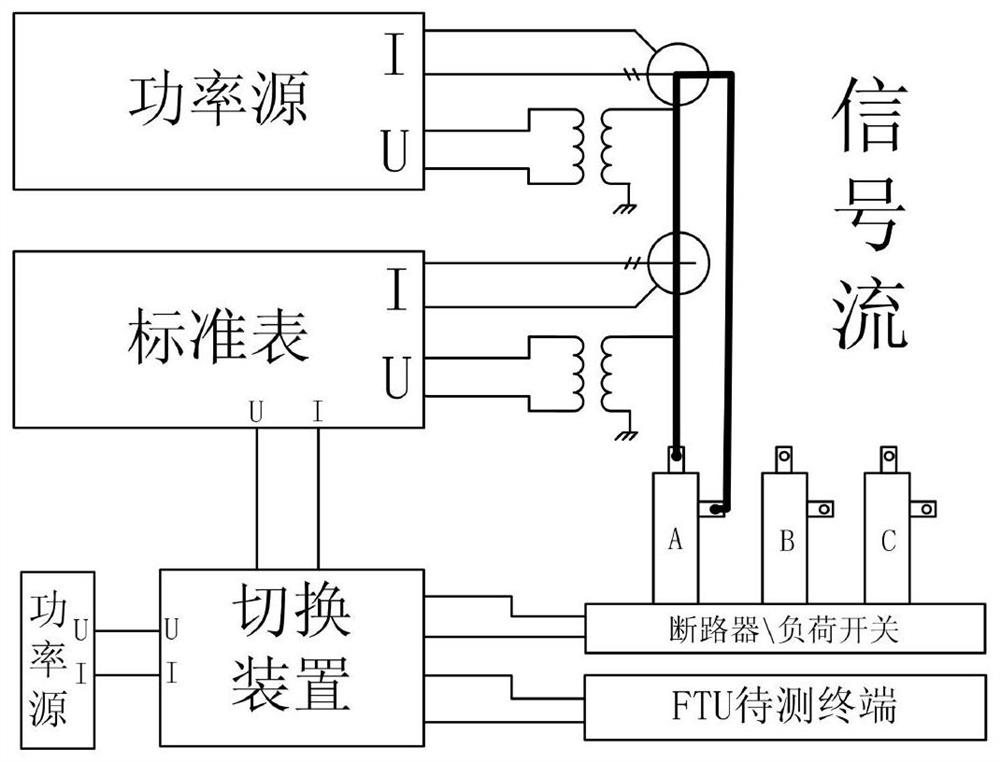

[0017] Embodiment 1: as Figure 1-Figure 3 As shown, a high-precision fault inversion method without static error automatic feedback, the method is: set preset fault scenarios of short circuit, grounding and anti-maloperation, and apply high-fidelity voltage on the primary side through software and hardware control, The current signal verifies the fault judgment, processing function and performance of the intelligent switch, and is used to verify the fault processing capability of a single device. At the hardware level, the fault inversion test system transfers the impedance of the load side to the source side through the impedance transfer method to control the current Using the current feedback method, through the fast-response non-static automatic feedback control circuit, driving the high-current MOS tube to generate a nonlinear voltage to drive the load circuit to obtain a high-precision primary signal, and then using the 2-way multi-channel high-precision synchronous samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com