Liquid crystal display panel

A liquid crystal display panel, glass substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as white point coordinate shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

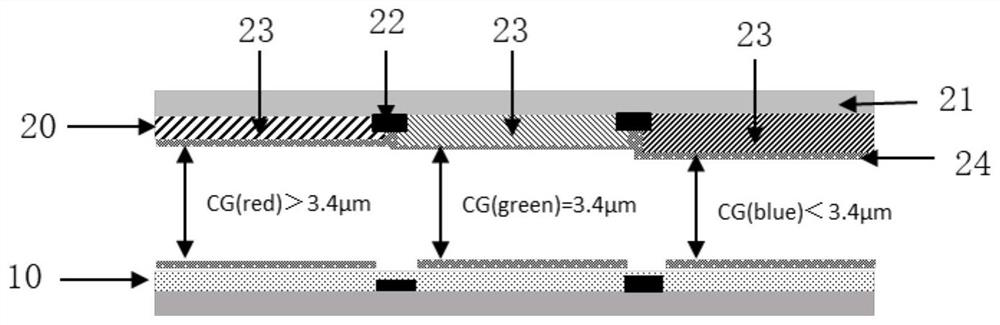

[0024] Such as Figure 4 As shown, the liquid crystal display panel includes an array substrate 10 and a color filter substrate 20 disposed opposite to each other, and a liquid crystal (not shown) located between the array substrate 10 and the color filter substrate 20 .

[0025] The array substrate 10 includes a first glass substrate 11, scan lines 12 and data lines 13 arranged in criss-cross arrangement on the glass substrate 11, a gate insulating layer (not shown) covering the scan lines 12, and a gate insulating layer located on the gate insulating layer. A semiconductor layer (not shown), an organic insulating layer 14 covering the scan lines 12 and data lines 13 , and a pixel electrode 15 on the organic insulating layer 14 .

[0026] The color filter substrate 20 includes a second glass substrate 21, a black matrix 22 on the second glass substrate 21, a plurality of colored layers between adjacent black matrices 22, and a flat layer 24 covering the black matrix 22 and th...

no. 2 example

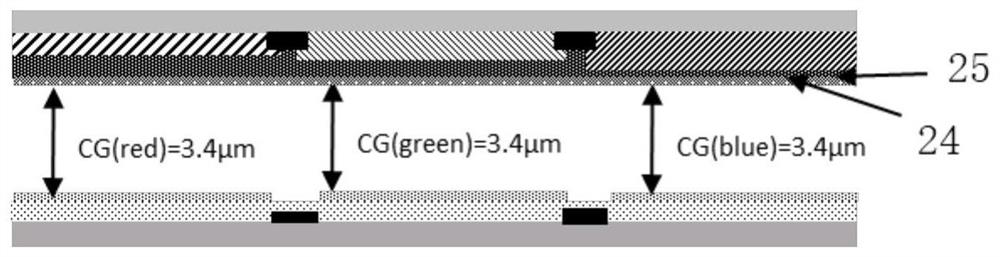

[0032] The difference from the first embodiment above is: H1>H2>H3, H1-H2=0.01 μm˜0.3 μm, H2-H1=0.01 μm˜0.3 μm.

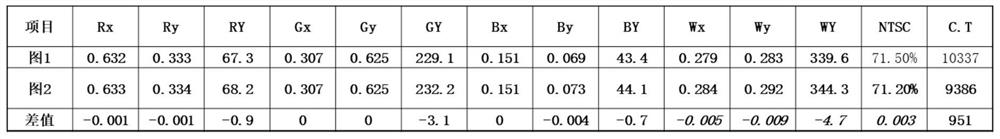

[0033] The cell thickness of the display area of the liquid crystal display panel is: the cell thickness CG(red)3.4μm, to increase the Wx value and Wy value of the panel (WX and WY are the coordinates of the white point).

[0034] The present invention forms organic insulating layers with inconsistent heights by exposing half-tone masks to achieve the purpose of adjusting the thickness of boxes corresponding to areas of different color layers and adjusting the chromaticity of panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com