Water-soluble dye coupled nano carbon black and preparation method thereof

A technology of water-soluble dyes and nano-carbon black, which is applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve problems such as easy agglomeration, color deviation of printed matter, and low production efficiency, and achieve improvement Effects of hiding power and gloss, improvement of storage stability, and enhancement of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

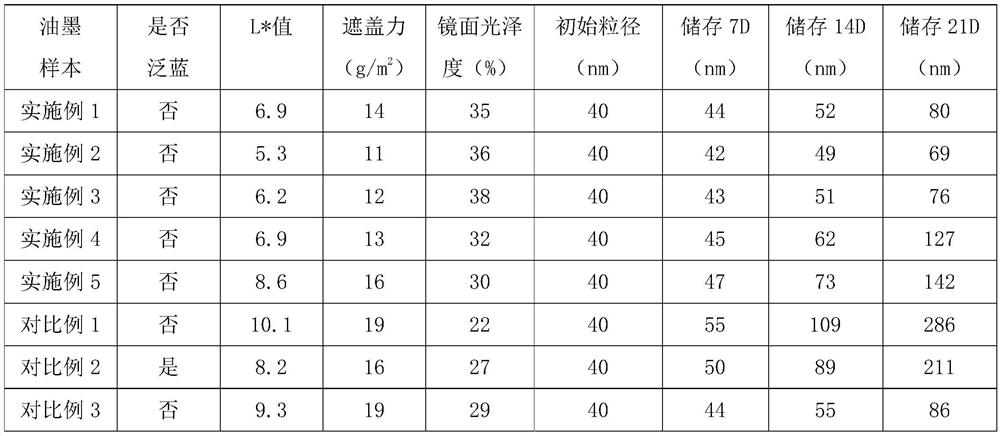

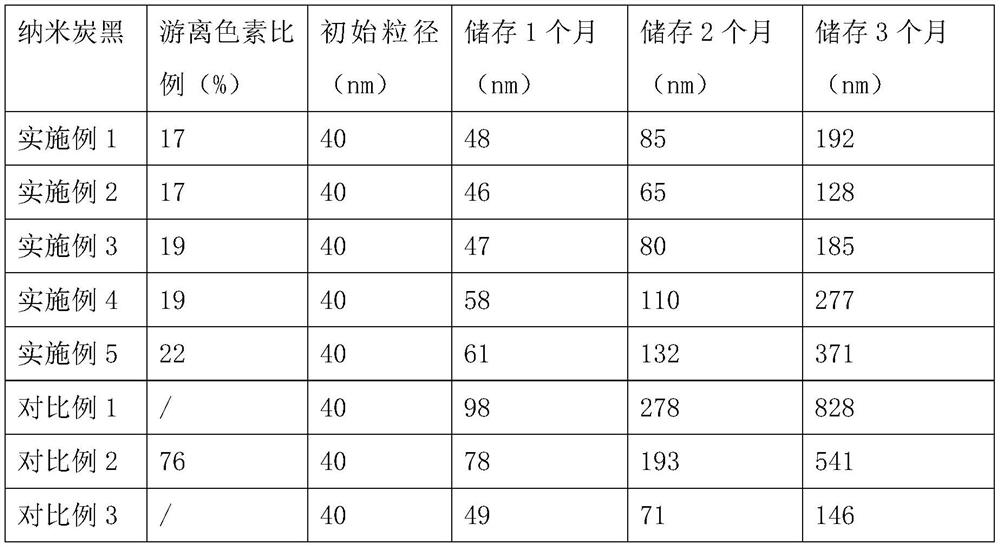

Examples

Embodiment 1

[0023] A kind of water-soluble dye coupling type nano carbon black, its preparation method is:

[0024] (1) Disperse the nano-carbon black in pure water of 3 times its mass multiple, and stir evenly;

[0025] (2) Add 1% hydrogen peroxide of nano-carbon black mass, after uniform dispersion, heat up to 40°C, and stir for 50min;

[0026] (3) Then add the water-soluble blue dye of nano carbon black quality 0.2‰, and disperse evenly;

[0027] (4) Add a silane coupling agent of 1% by mass of nano-carbon black, adjust the temperature to 55° C., and react for 1 h;

[0028] (5) After the reaction is completed, continue to add 1% gum arabic of the nano-carbon black quality, after the dispersion is uniform, spray drying under reduced pressure, and the gained is the water-soluble dye-coupled nano-carbon black;

[0029] (6) Sealed packaging, waterproof storage, spare.

[0030] The particle size of the nano-carbon black is 40nm.

[0031] The water-soluble blue dye described in step (3) ...

Embodiment 2

[0035] A kind of water-soluble dye coupling type nano carbon black, its preparation method is:

[0036] (1) Nano carbon black is dispersed in the pure water of its mass multiple 4 times, and stir;

[0037] (2) Add 3% hydrogen peroxide of nano-carbon black mass, after uniform dispersion, heat up to 45°C, and stir for 40min;

[0038] (3) Then add the water-soluble blue dye of nano carbon black quality 0.5‰, and disperse evenly;

[0039] (4) Add a silane coupling agent of 2% by mass of nano-carbon black, adjust the temperature to 50° C., and react for 1.5 hours;

[0040] (5) After the reaction is completed, continue to add the gum arabic of 1.5% of the nano-carbon black quality, after the dispersion is uniform, spray dry under reduced pressure, and the gained is the water-soluble dye-coupled nano-carbon black;

[0041] (6) Sealed packaging, waterproof storage, spare.

[0042] The particle size of the nano-carbon black is 40nm.

[0043] The water-soluble blue dye described in ...

Embodiment 3

[0047] A kind of water-soluble dye coupling type nano carbon black, its preparation method is:

[0048] (1) Nano carbon black is dispersed in the pure water of its mass multiple 5 times, and stir;

[0049] (2) Add 5% hydrogen peroxide of nano-carbon black mass, after uniform dispersion, heat up to 50°C, and stir for 30min;

[0050] (3) Then add the water-soluble blue dye of nano carbon black quality 0.8‰, and disperse evenly;

[0051] (4) Add 3% silane coupling agent of nano-carbon black mass, adjust the temperature to 45° C., and react for 2 hours;

[0052] (5) After the reaction is completed, continue to add the gum arabic of 2% of the nano carbon black quality, after the dispersion is uniform, spray drying under reduced pressure, and the gained is the water-soluble dye-coupled nano carbon black;

[0053] (6) Sealed packaging, waterproof storage, spare.

[0054] The particle size of the nano-carbon black is 40nm.

[0055] The water-soluble blue dye described in step (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com