Method for manufacturing multi-layered fibrous web and multi-layered fibrous web

A multi-layer fiber and fiber layer technology, which is applied in the direction of secondary cellulose fiber, non-fiber pulp addition, fiber raw material treatment, etc., can solve the problems of impact, drainage and retention rate, etc., to eliminate foaming problems and improve reliability. operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

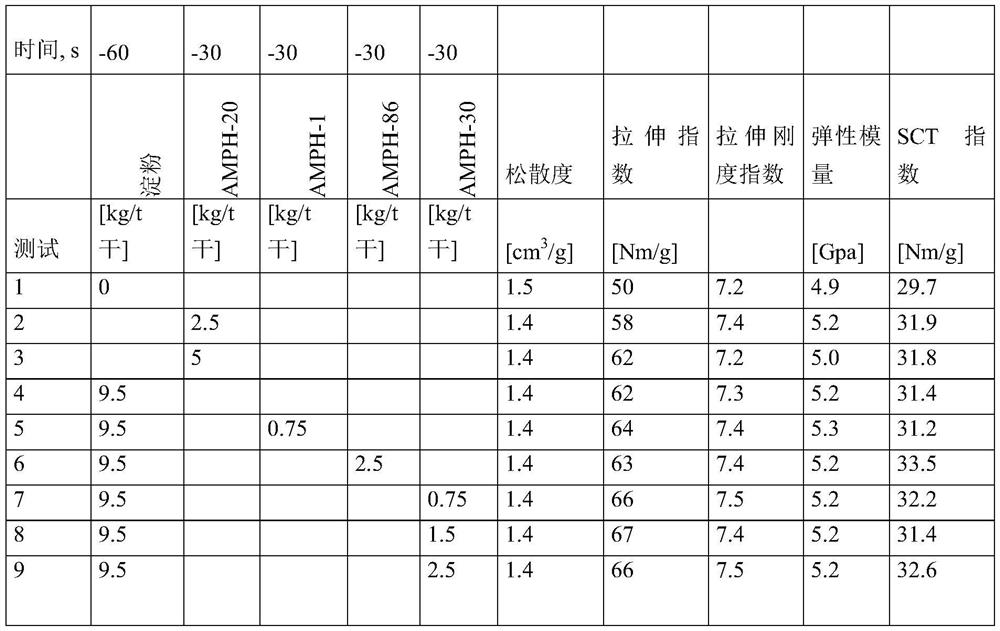

Examples

Embodiment approach

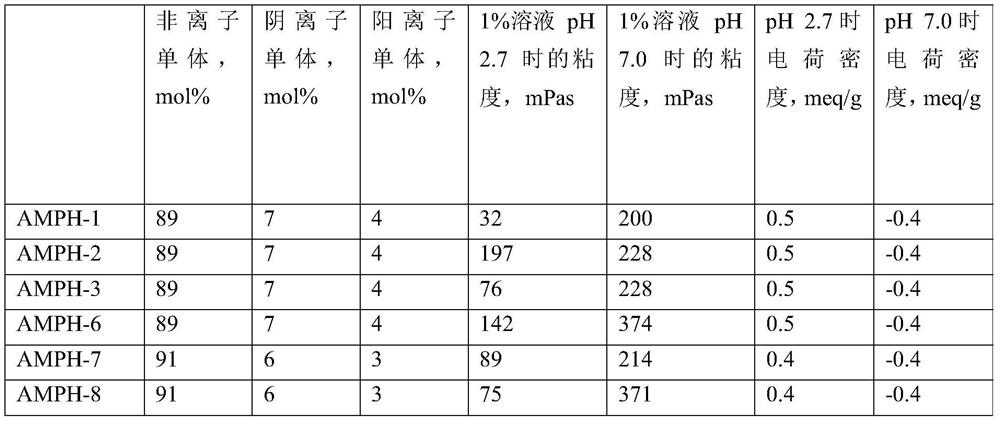

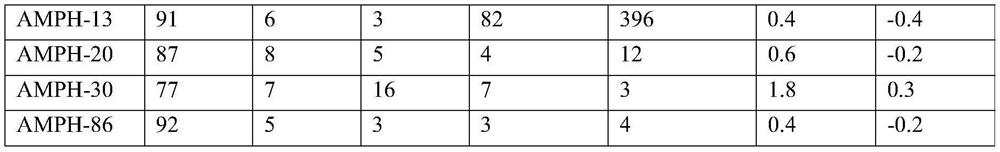

[0040] According to one embodiment of the present invention, the synthetic amphoteric polymer composition comprises

[0041] - one or more copolymers of anionic vinyl monomers, cationic vinyl monomers and nonionic vinyl monomers, and / or

[0042] - Combinations of copolymers comprising anionic vinyl monomers and nonionic vinyl monomers with copolymers comprising cationic vinyl monomers and nonionic vinyl monomers.

[0043]The cationic groups in the synthetic amphoteric polymer composition may be derived from 2-(dimethylamino)ethyl acrylate (ADAM), [2-(acryloyloxy)ethyl]trimethylammonium chloride ( ADAM-Cl), 2-(dimethylamino)ethyl acrylate benzyl chloride, 2-(dimethylamino)ethyl acrylate dimethyl sulfate, 2-dimethylaminoethyl methacrylate (MADAM), [2 -(methacryloyloxy)ethyl]trimethylammonium chloride (MADAM-Cl), 2-dimethylaminoethyl methacrylate dimethylsulfate, [3-(acryloylamino)propyl Monomers of ]trimethylammonium chloride (APTAC), [3-(methacrylamino)propyl]trimethylammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com