Agricultural wheat harvester capable of achieving straw smashing and returning to field

A straw crushing and harvesting machine technology, applied in agricultural machinery and tools, agriculture, application, etc., can solve the problems of heavy workload, inconvenient use, etc., and achieve the effect of increasing moisture, good crushing effect, and convenient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

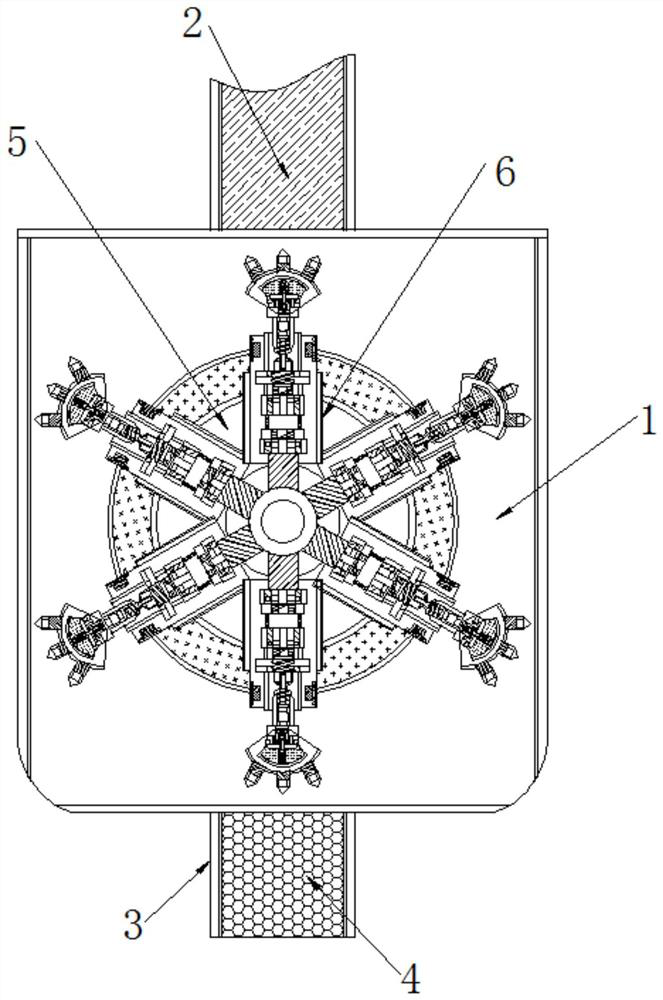

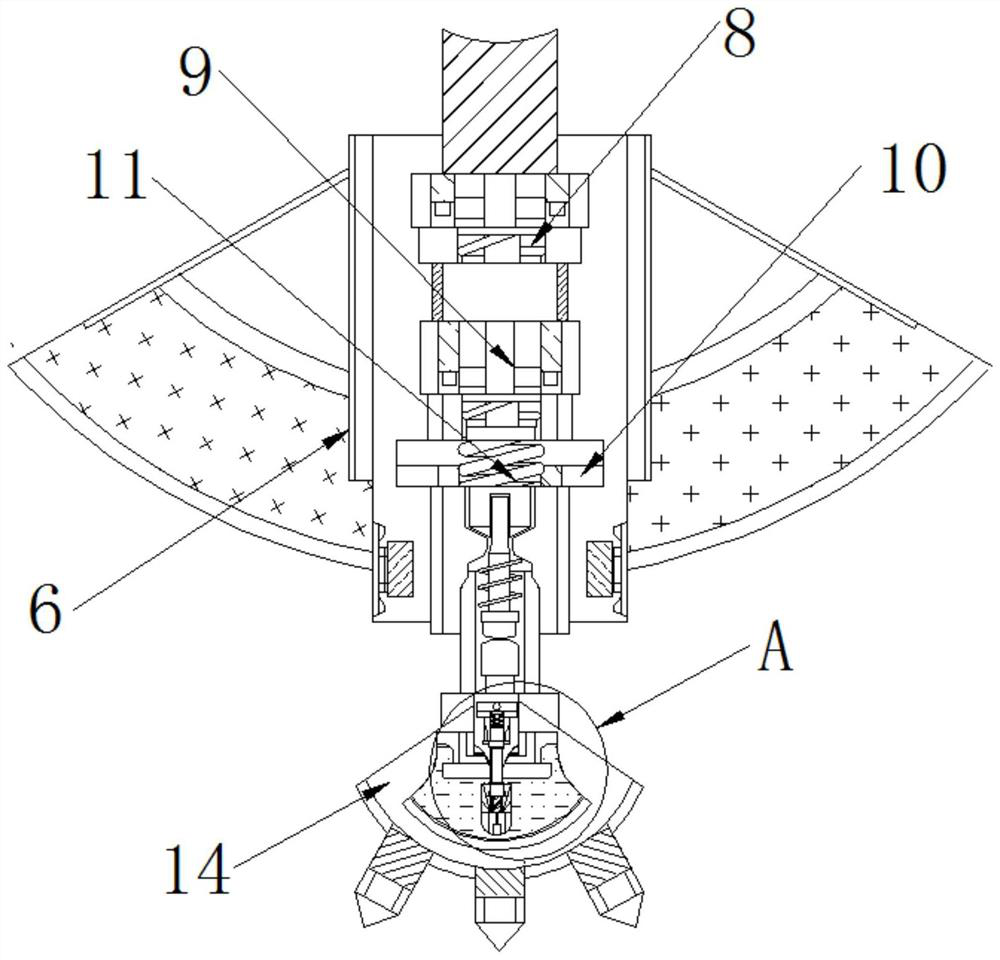

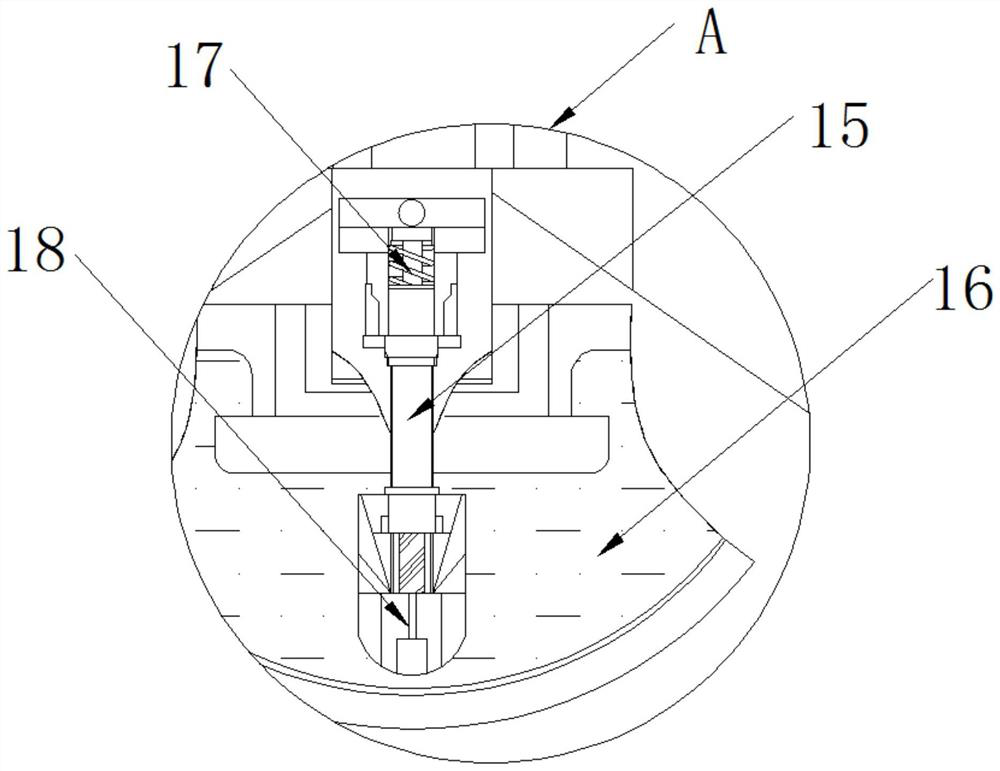

[0021] as attached figure 1 to attach Figure 5 Shown:

[0022] The present invention provides an agricultural wheat harvester capable of crushing straw and returning it to the field, comprising a crushing seat 1, the outer surface of the crushing seat 1 is fixedly connected with a feed pipe 2, and the lower surface of the crushing seat 1 is fixedly connected with a discharge pipe 3 , the inside of the discharge pipe 3 is provided with a discharge hole 4, the inside of the crushing seat 1 is connected with a rotating disk 5, the inside of the crushing seat 1 is provided with a rotating shaft suitable for the rotating disk 5, and one end of the discharge pipe 3 Through the inside of the crushing seat 1, the outer surface of the rotating disk 5 is fixedly connected with a protective seat 6, the inside of the protective seat 6 is fixedly connected with a sliding rail 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com