A digital metal gingival wall lifting guide plate and its manufacturing method

A manufacturing method and lifting plate technology, which are applied in metal processing equipment, manufacturing tools, design optimization/simulation, etc., can solve problems such as low operation efficiency, poor restoration effect of defective teeth, poor gingival morphology, etc., and achieve a wide range of indications , Preventing poor gingival shape and better repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

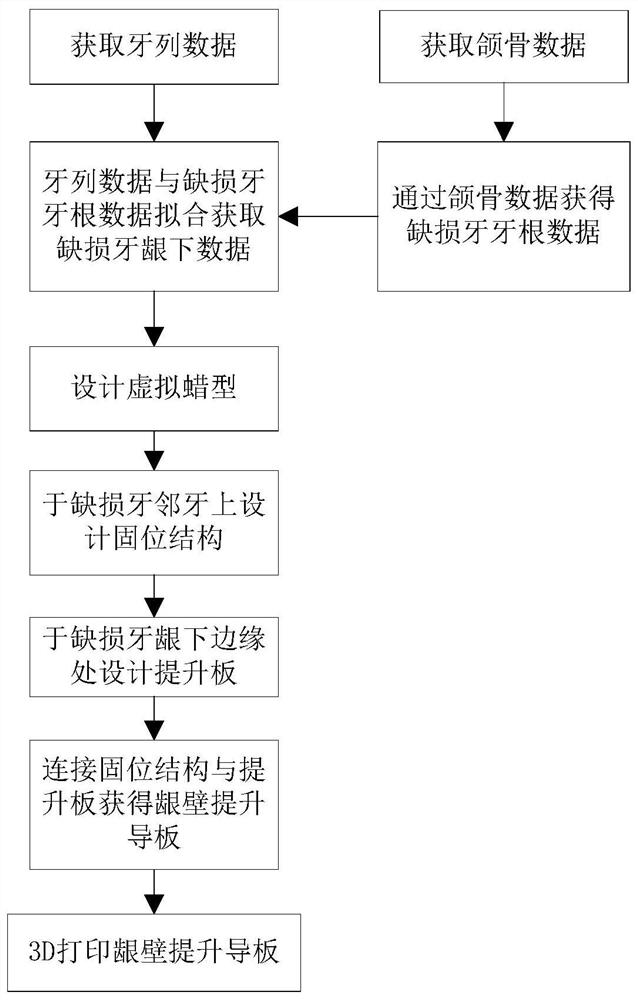

[0057] Such as Figure 1-Figure 6 as well as Figure 9As shown, the manufacturing method of the metal gingival wall lifting guide plate includes the following steps:

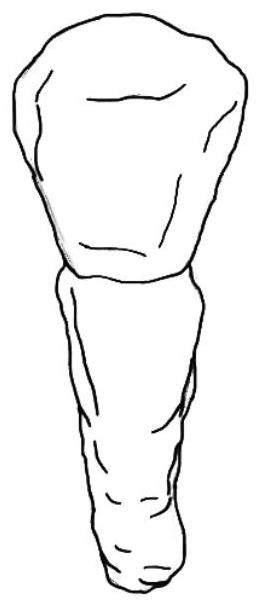

[0058] Step 1: Obtain dentition data through intraoral scanner, obtain jaw data through dental CBCT equipment, the data format is .dicom, use dental software exocad to convert dicom data into stl data, edit jaw data, and obtain defective teeth 1 root data;

[0059] Step 2: Fit the dentition data with the root data of the defective tooth 1 to obtain the subgingival data of the defective tooth 1, edit the dentition data, expose the root of the defective tooth 1, obtain the anatomical shape of the root, and obtain the complete data of the defective tooth 1;

[0060] Step 3: Design a virtual wax-up based on the complete data of the defective tooth 1;

[0061] Step 4: On the basis of the virtual wax-up, an occlusal surface retention plate 2 is designed at the adjacent tooth of the defective tooth 1, and the occlus...

Embodiment 2

[0072] Such as Figure 1-Figure 4 as well as Figure 7-Figure 8 As shown, the manufacturing method of the metal gingival wall lifting guide plate includes the following steps:

[0073] Step 1: Obtain the dentition data through the dental model scanner, obtain the jaw data through the dental CBCT equipment, edit the jaw data, and obtain the root data of the defective tooth 1;

[0074] Step 2: Fit the dentition data with the root data of the defective tooth 1 to obtain the subgingival data of the defective tooth 1, edit the dentition data, expose the root of the defective tooth 1, obtain the anatomical shape of the root, and obtain the complete data of the defective tooth 1;

[0075] Step 3: Design a virtual wax-up based on the complete data of the defective tooth 1;

[0076] Step 4: On the basis of the virtual wax-up, design a clasp-type structure at the defective tooth 1, and the clasp-type structure is fixed around the adjacent teeth of the defective tooth 1;

[0077] Step...

Embodiment 3

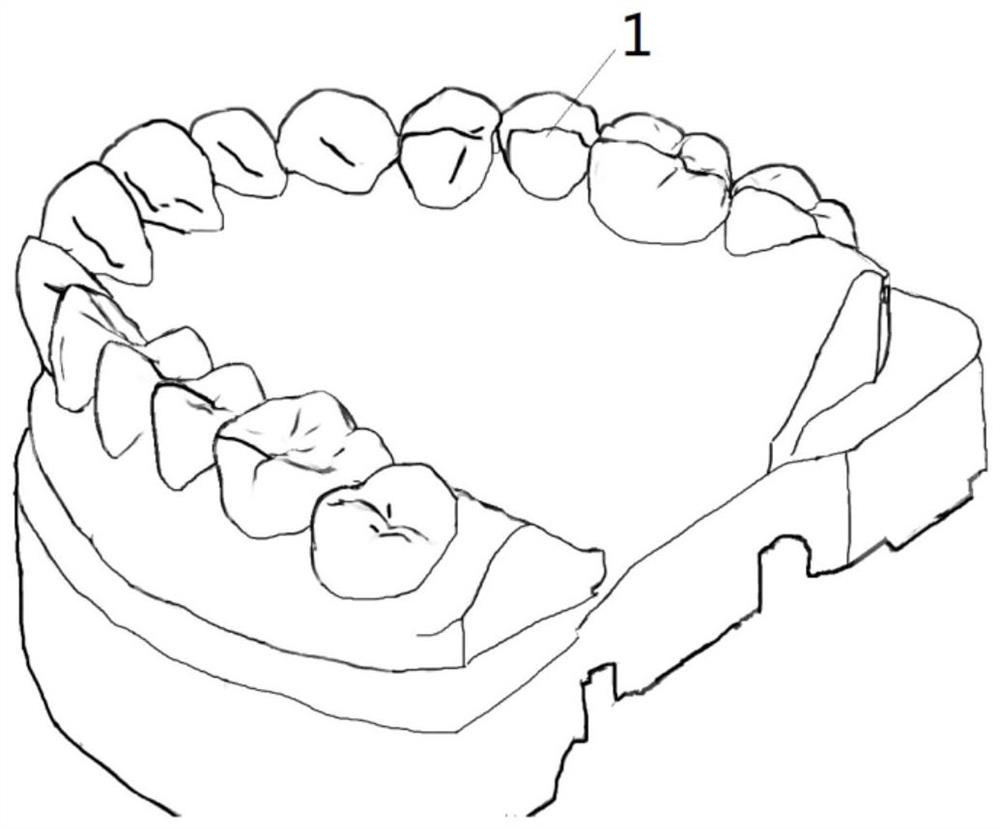

[0083] Such as Figure 5 and Figure 6 As shown, a metal gingival wall lifting guide plate includes a retention structure and a lifting plate, the retention structure is connected to the lifting plate, and the retention structure and the lifting plate are integrally formed by 3D printing.

[0084] The retention structure is an occlusal surface retention plate 2, and the two ends of the occlusal surface retention plate 2 are respectively connected with the adjacent teeth of the defective tooth 1.

[0085] The two ends of the occlusal surface retention plate 2 are covered on the teeth adjacent to the defective tooth 1, and the lifting plate is located at the defective tooth 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com