Efficient supporting layer structure for advanced treatment of filter material

A technology of advanced treatment and filter material layer, which is applied in the direction of loose filter material filter, filter separation, gravity filter, etc., can solve the problems of lower operating cost, short service life of filter material, large water resource consumption, etc., and achieve improvement Effects of backwash strength, service life extension, and operating cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

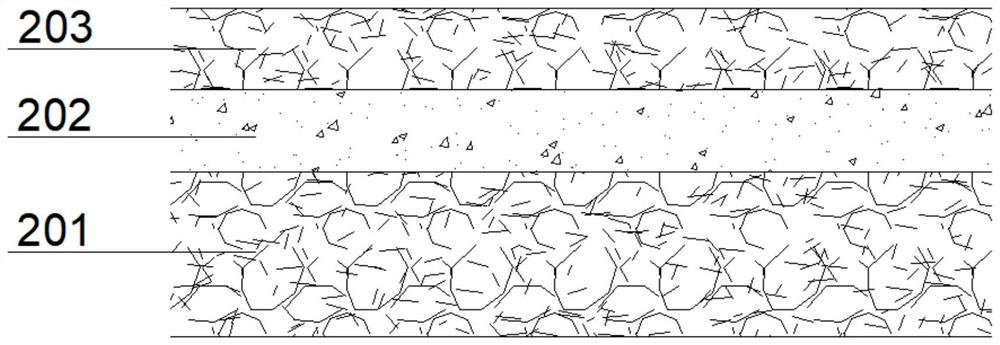

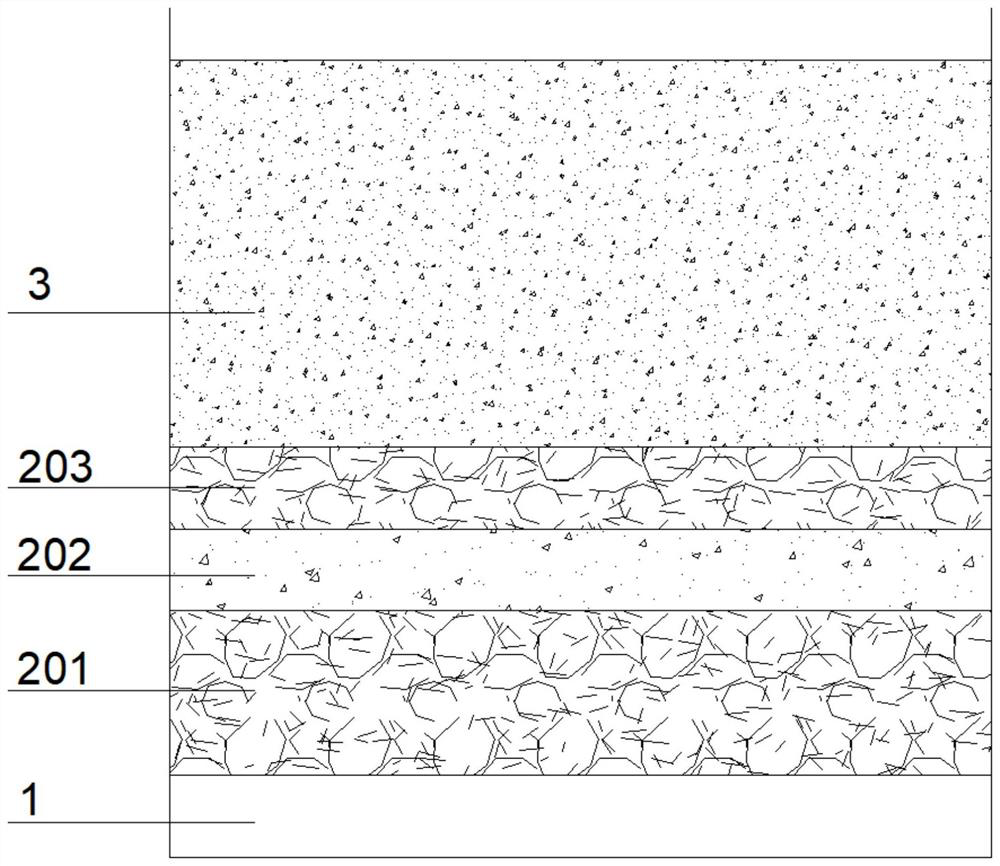

[0024] Such as figure 2 As shown, the bottom of the advanced treatment filter is first installed with water distribution and air distribution devices to form a water distribution and air distribution layer 1, and then the first layer of large particle size filter material layer 201 of the high-efficiency supporting layer structure of the advanced treatment filter material, The second layer of large particle size filter material layer 202 and the third layer of large particle size filter material layer 203 are sequentially filled above the water distribution and air distribution layer 1, and finally the upper special effect filter material layer is filled above the support layer 2 3. The height of the advanced treatment filter and the thickness of each layer of the high-efficiency supporting layer are determined according to the influent water quality, and the upper limit of the particle size range of the first layer of large particle size filter material layer 201 is used as ...

Embodiment 2

[0026] Such as figure 2 As shown, the bottom of the reclaimed water reuse filter tank is first installed with water distribution and air distribution devices to form a water and air distribution layer 1, and then the first layer of large particle size filter material layer of the high-efficiency supporting layer structure of the advanced treatment filter material 201, the second layer of medium and large particle size filter material layer 202, the third layer of large particle size filter material layer 203 are filled in sequence above the water distribution and gas distribution layer 1, and finally the upper special filter layer is filled above the support layer 2 Layer 3. The height of the reclaimed water reuse filter tank and the thickness of each layer of the high-efficiency supporting layer are determined according to the influent water quality, and the upper limit of the particle size range of the first layer of large particle size filter material layer 201 is used as ...

Embodiment 3

[0028] Such as figure 2 As shown, the bottom of the advanced treatment filter tank is first installed with water distribution and air distribution devices to form a water distribution and air distribution layer 1, and then the first layer of large particle size filter material layer 201 of the high-efficiency supporting layer structure of the advanced treatment filter material, The second layer of large particle size filter material layer 202 and the third layer of large particle size filter material layer 203 are sequentially filled above the water distribution and air distribution layer 1, and finally the upper special effect filter material layer is filled above the supporting layer 2 3. The height of the advanced treatment filter tank and the thickness of each layer of the high-efficiency supporting layer are determined according to the influent water quality, and the upper limit of the particle size range of the first layer of large particle size filter material layer 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com