Manufacturing equipment and manufacturing method of inspection well

A production method and inspection well technology are applied in the design field of processing and production equipment, which can solve the problems of high labor intensity, high error rate, inaccurate position of polyethylene materials, etc., and achieve highly controllable forming, precise and controllable position, Good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

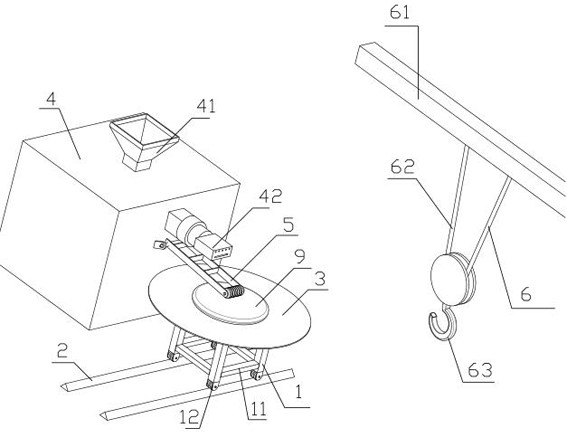

[0045] Example 1, such as figure 1 As shown, a manufacturing equipment and manufacturing method of an inspection well, the entire manufacturing equipment of the inspection well includes two parts, which are respectively the bottom cover manufacturing device and the body transportation device 6, respectively in figure 1 The left part of the figure and the right part of the figure.

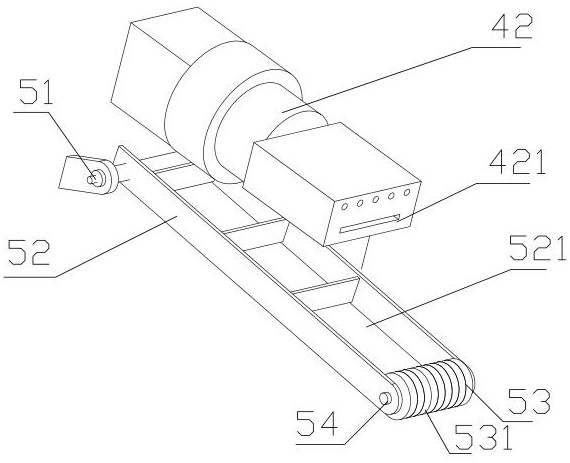

[0046] The bottom cover making device comprises a discharge device 4, and the discharge device 4 comprises a feed box 41 and an extrusion device 42, and the material for making the bottom cover, such as polyethylene, is placed in the feed case 41 and passed through the extrusion device 42 extrude. As for the material box 41 and the extruding device 42, this part is the content of the prior art, and this solution does not make any changes to these two components, and will not repeat them here.

[0047] The bottom cover manufacturing device also includes a turntable 3, and the turntable 3 is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com