Full-automatic production line and method for finished spooled yarn sorting, film sealing and packaging

A fully automatic, production-line technology, applied in automatic control of packaging, decomposition and recovery of textiles, packaging, etc., can solve problems such as low production efficiency and high labor intensity of workers, achieve convenient workshop management, improve quality control, and stress Even and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

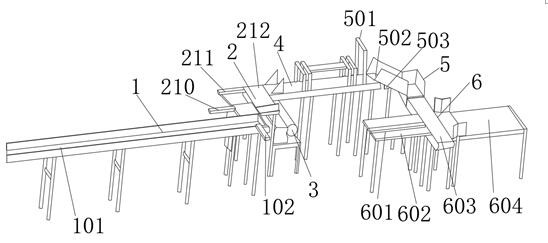

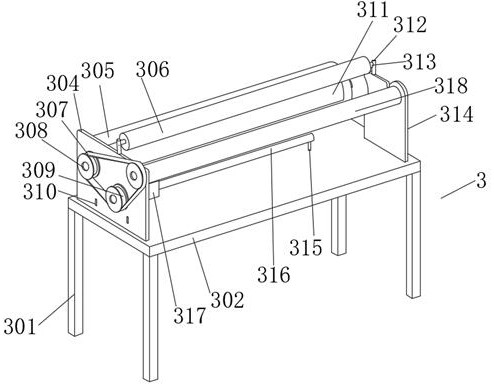

[0027] Embodiment 1: as Figure 1-4 As shown, the fully automatic production line for sorting, sealing, and packaging finished winding yarns includes a feeding structure 1, a weight plate assembly mechanism 2 is fixedly installed on one side of the material loading structure 1, and a feeding mechanism 2 is fixedly installed on one side of the weight plate assembly mechanism 2. Film mechanism 3, a film sealing mechanism 4 is fixedly installed on one side of the film feeding mechanism 3, a turning mechanism 5 is fixed on one side of the sealing mechanism 4, and a packaging mechanism 6 is fixedly installed on one side of the turning mechanism 5.

[0028] Wherein, the feeding structure 1 includes a first conveyor belt 101 and a weighing feeding cylinder 102 , and one end side of the first conveyor belt 101 is fixedly installed with a weighing feeding cylinder 102 .

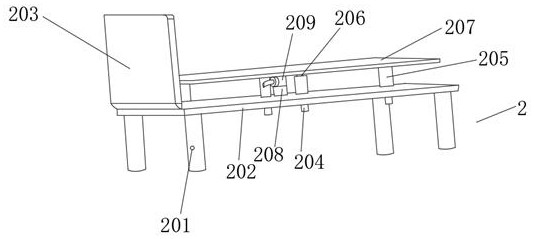

[0029] Wherein, the weight plate assembly mechanism 2 includes a weighing plate bottom column 201, a weighing plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap