Smoke treatment device, smoke treatment system and smoke treatment method

A technology for flue gas treatment and flue gas, which is applied in waste heat treatment, climate sustainability, and greenhouse gas reduction, and can solve problems such as white smoke from chimneys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

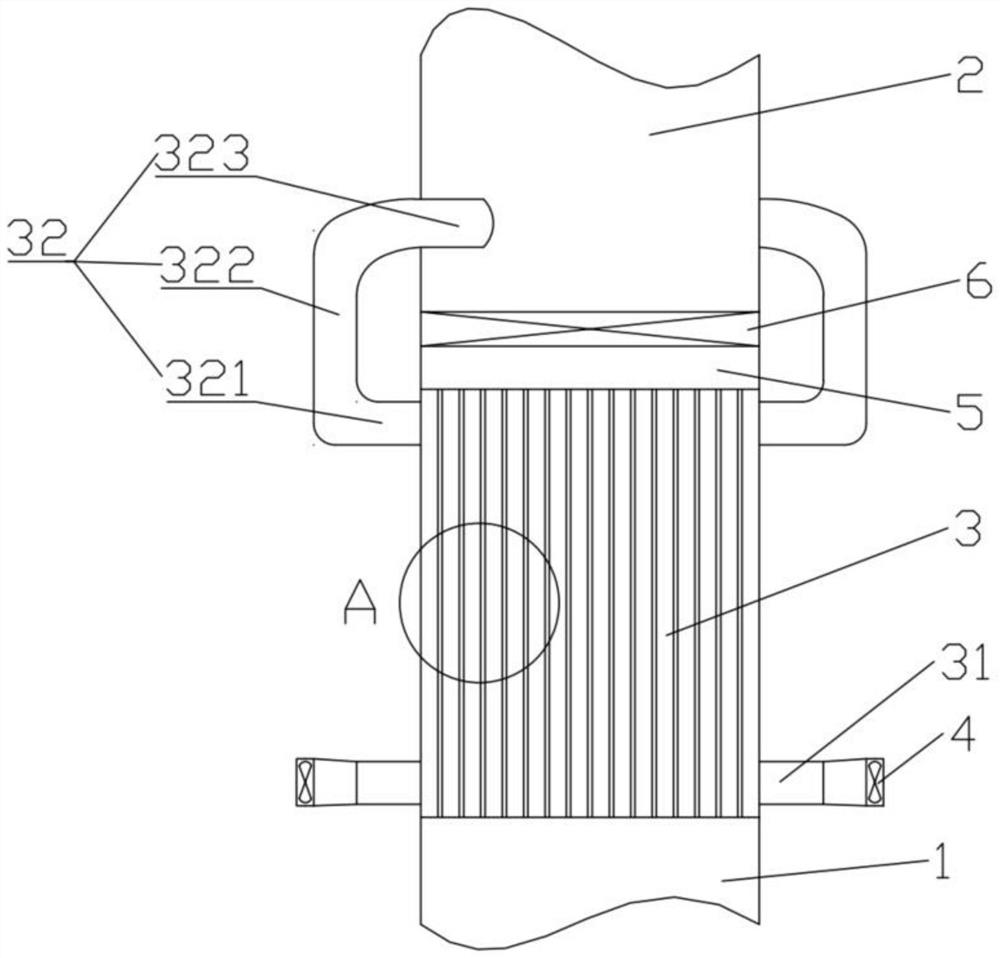

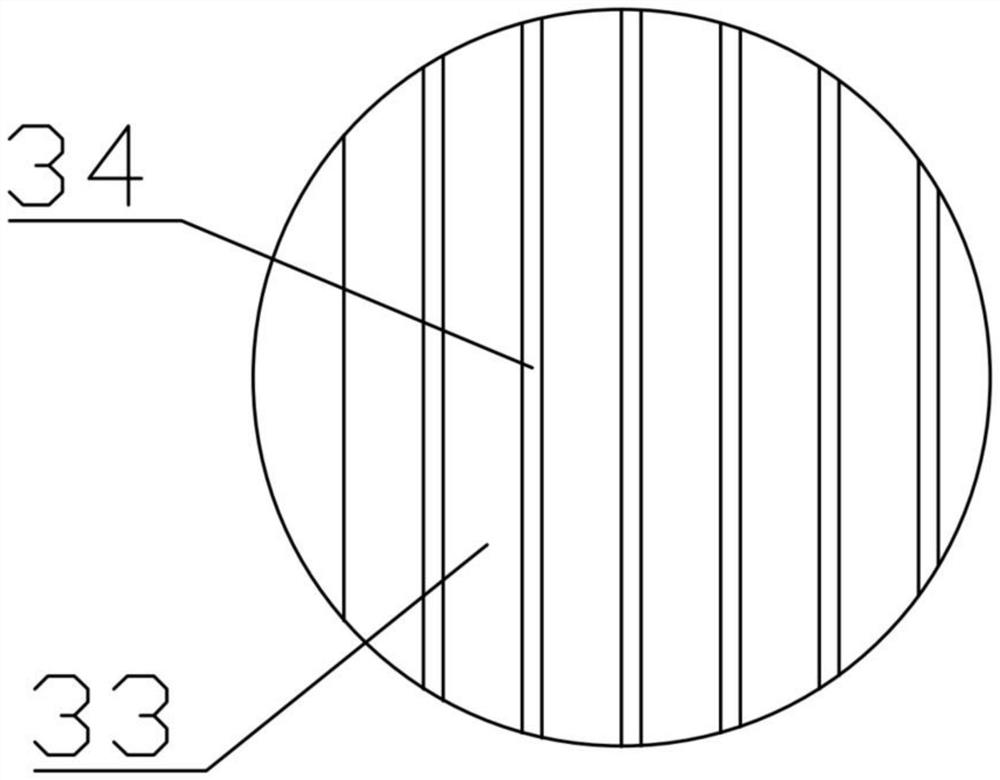

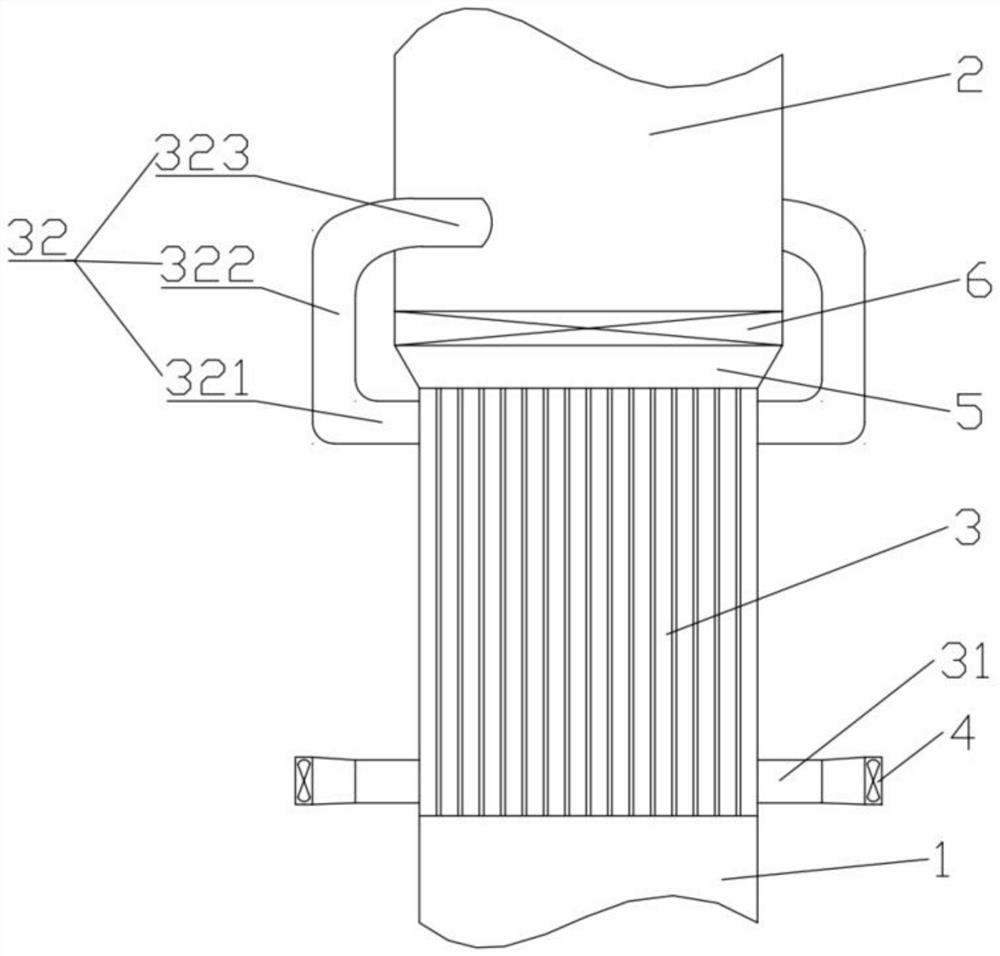

[0041] In order to solve the problem that the existing flue gas treatment system tends to emit white smoke in the process of flue gas discharge after the flue gas is treated, as attached Figure 1-2 As shown, this embodiment proposes a flue gas treatment device. The flue gas treatment device includes a flue gas inlet pipe 1, a flue gas outlet pipe 2, and a heat exchange device 3. The flue gas inlet pipe 1 and the heat exchange device 3 The inlet of the flue gas passage 34 is connected, and the flue gas outlet pipe 2 is connected with the outlet of the flue gas passage 34 of the heat exchange device 3. The heat exchange device 3 is provided with an air inlet pipe 31 and an air outlet pipe 32. The air outlet The inlet end of the pipe 32 communicates with the outlet of the air channel 33 of the heat exchange device 3 , and the outlet end of the air outlet pipe 32 communicates with the flue gas outlet pipe 2 , so that the air after heat exchange and the flue gas are mixed in the ai...

Embodiment 2

[0050] Considering that in the flue gas channel 34, the flue gas often has a relatively high flow rate, after heat exchange, it will still carry a part of the condensed water droplets to move upwards and enter the flue gas outlet pipe 2, and this part of the condensed water droplets will be It affects the humidity of the mixed flue gas, which is not conducive to ensuring the elimination of white smoke from the chimney.

[0051] Therefore, in order to solve this problem, the attached Figure 1-3 As shown, this embodiment further improves the flue gas treatment device on the basis of embodiment 1, specifically:

[0052] A deceleration pipe 5 is arranged between the flue gas outlet pipe 2 and the heat exchange device 3 , the inlet end of the deceleration pipe 5 communicates with the flue gas passage 34 of the heat exchange device 3 , and the outlet end of the deceleration pipe 5 It communicates with the flue gas outlet pipe 2; wherein, the cross-sectional area of the decelerat...

Embodiment 3

[0058] In the flue gas outlet pipe 2, in order to ensure that the low temperature flue gas is fully mixed with the hot dry air, as attached Figure 1-4 As shown, this embodiment further improves the flue gas treatment device on the basis of embodiment 1 or embodiment 2, specifically:

[0059] The inlet end of the flue gas outlet pipe 2 communicates with the outlet of the flue gas channel 34 of the heat exchange device 3, and the outlet end of the flue gas outlet pipe 2 communicates with the chimney or the external atmosphere, thereby ensuring that the flue gas is It can be discharged through the inlet end of the flue gas outlet pipe 2 and the outlet end of the flue gas outlet pipe 2 in sequence.

[0060] At the same time, a mixing space 21 is provided in the flue gas outlet pipe 2 to provide a space for the mixing process of low-temperature flue gas formed after heat exchange and hot dry air.

[0061] The air outlet pipe 32 communicates with the smoke outlet pipe 2, specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com