Tunable FP optical filter based on lithium niobate film

A lithium niobate and optical filter technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of slow tuning speed, large optical loss, poor stability, etc., to reduce optical loss, good temperature stability, high The effect of electro-optic coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

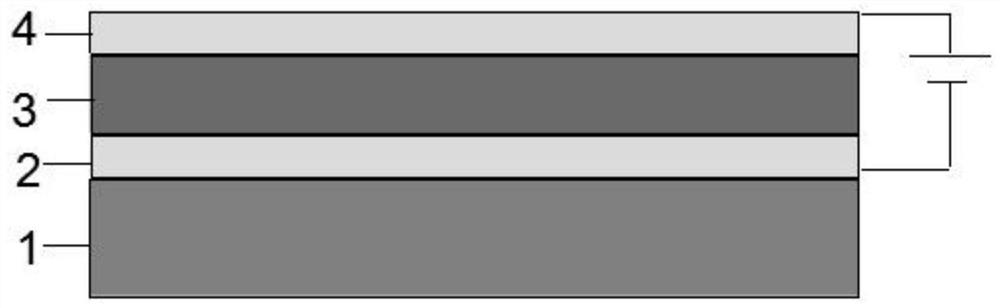

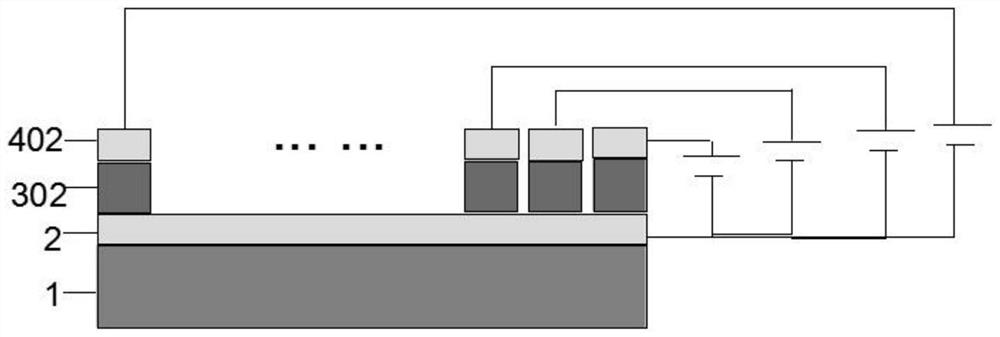

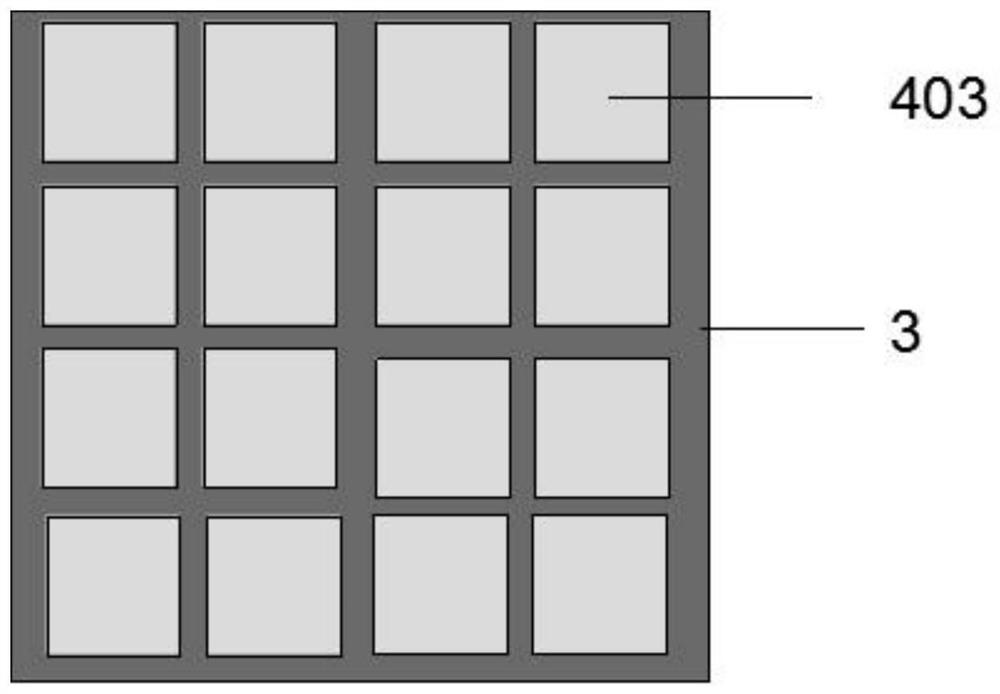

[0058] Such as figure 1 As shown, a tunable FP filter based on a lithium niobate thin film in this embodiment includes a substrate 1, a first metal layer 2, an electro-optic tunable lithium niobate thin film light-passing layer 3, and a second metal layer 4 , by controlling the voltage between the first metal layer 2 and the second metal layer 4, the central wavelength of the tunable FP filter of the present invention of the tunable filter can be adjusted.

[0059] Wherein, the substrate 1 is other high light-transmitting materials such as quartz glass or K9 glass with high light transmittance; the first metal layer 2 is placed on the substrate 1 as a lower reflection layer and an electrode layer, and the material is Al , Ag, etc., with a thickness of 10nm-30nm; the lithium niobate thin film 3 is placed on the first metal layer 2 as a half-wave resonant cavity light-passing layer, and the thickness of the lithium niobate thin film layer is λ / (2n), where λ is designed Central ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com