Preparation method of tunable FP optical filter based on film bonding

A filter and thin film technology, applied in the field of preparation of tunable FP filters, can solve the problems of difficult process and low yield, achieve high electro-optic coefficient, good temperature stability, and improve processing technology. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

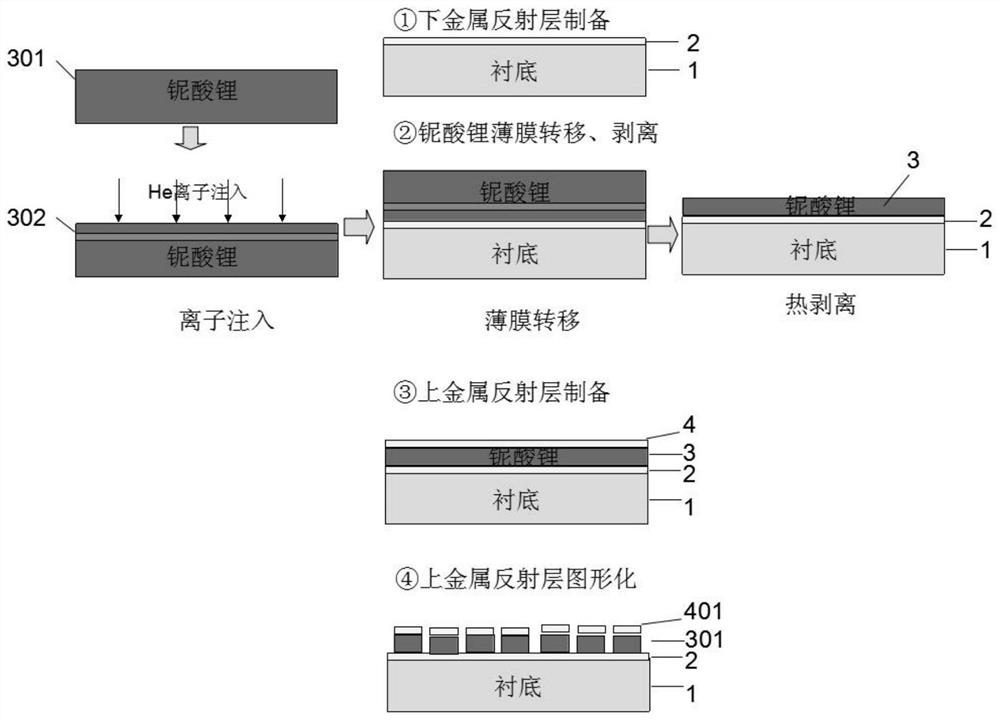

[0037] In order to solve the problems of the prior art, the present invention provides a method for preparing a tunable FP filter based on thin film bonding, such as figure 1 As shown, the method includes the following steps:

[0038] Step 1: Make the lower metal reflective layer;

[0039] The lower metal reflection layer of the FP filter is prepared by thermal evaporation coating method on the substrate;

[0040] Step 2: Preparation of the light-transmitting layer of the lithium niobate thin film:

[0041] The light-transmitting layer of lithium niobate thin film was prepared by ion implantation and bonding stripping method;

[0042] Step 3: Prepare the upper metal reflective layer:

[0043] The upper metal reflective layer is prepared by the method of magnetron sputtering;

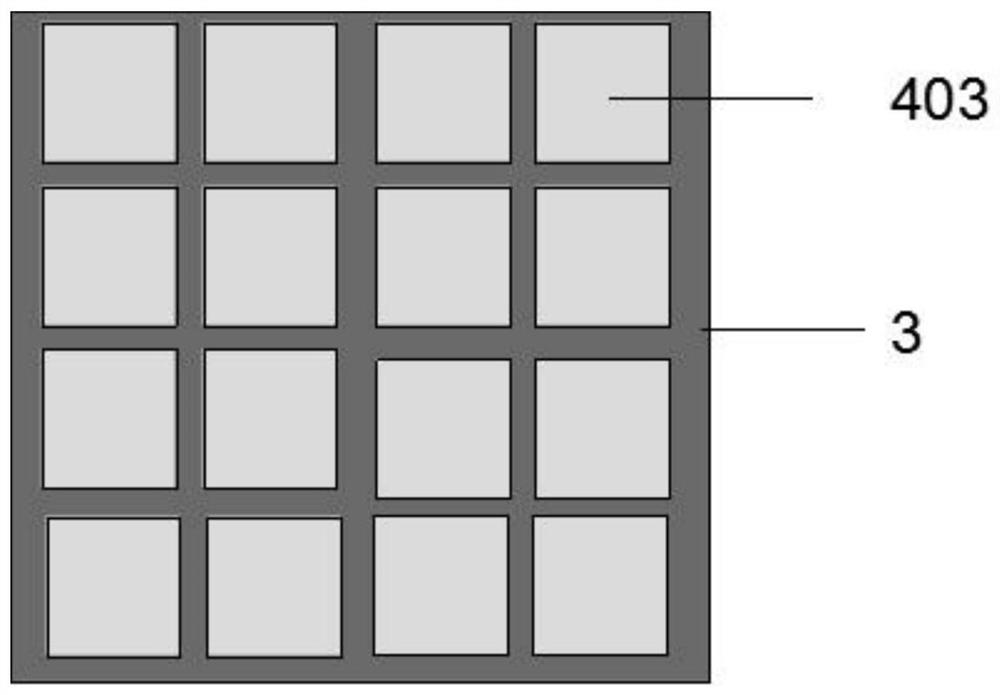

[0044] Step 4: Patterning preparation of the upper metal reflective electrode:

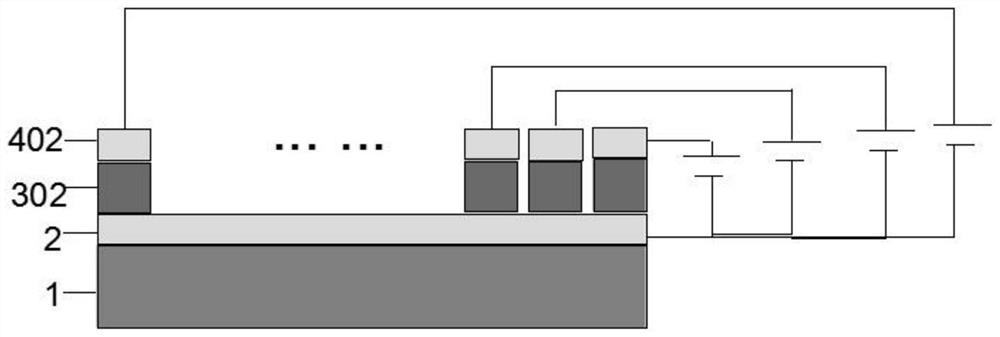

[0045] The upper metal electrode structure is fabricated by photolithography and ion beam etching process, and the tu...

Embodiment 1

[0058] like figure 1 As shown, this embodiment provides a method for preparing a tunable FP filter based on thin film transfer bonding, including the following steps:

[0059] ①The production of the lower metal reflection layer 2: Quartz glass, K9 glass or other highly transparent glass materials are firstly selected as the substrate 1; The material is Al, Ag, etc., and the reflectivity is required to be better than 90%;

[0060] ②Preparation of the light-transmitting layer 3 of the lithium niobate thin film: firstly, H ion implantation is performed on the surface of 301 on the lithium niobate substrate, and the lithium niobate implanted surface is bonded to the lower metal reflective layer 2 in the substrate 1 at the wafer level. The lithium niobate substrate 301 is removed by a thermal stripping method, leaving a bonded structure substrate with the lithium niobate film 3 and the lower metal reflective layer 2 to obtain the lithium niobate film light-transmitting layer 3;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com