General cremation machine quality detection system based on PXI platform

A technology of detection system and quality detection method, which is applied in the field of general cremation machine quality detection system, can solve the problems of inability to fully restore the cremation machine working state, insufficient cremation machine quality detection ability, backward detection data collection method, etc., to achieve efficient and fast The effect of data acquisition ability, powerful data processing and analysis ability, and fast data acquisition response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

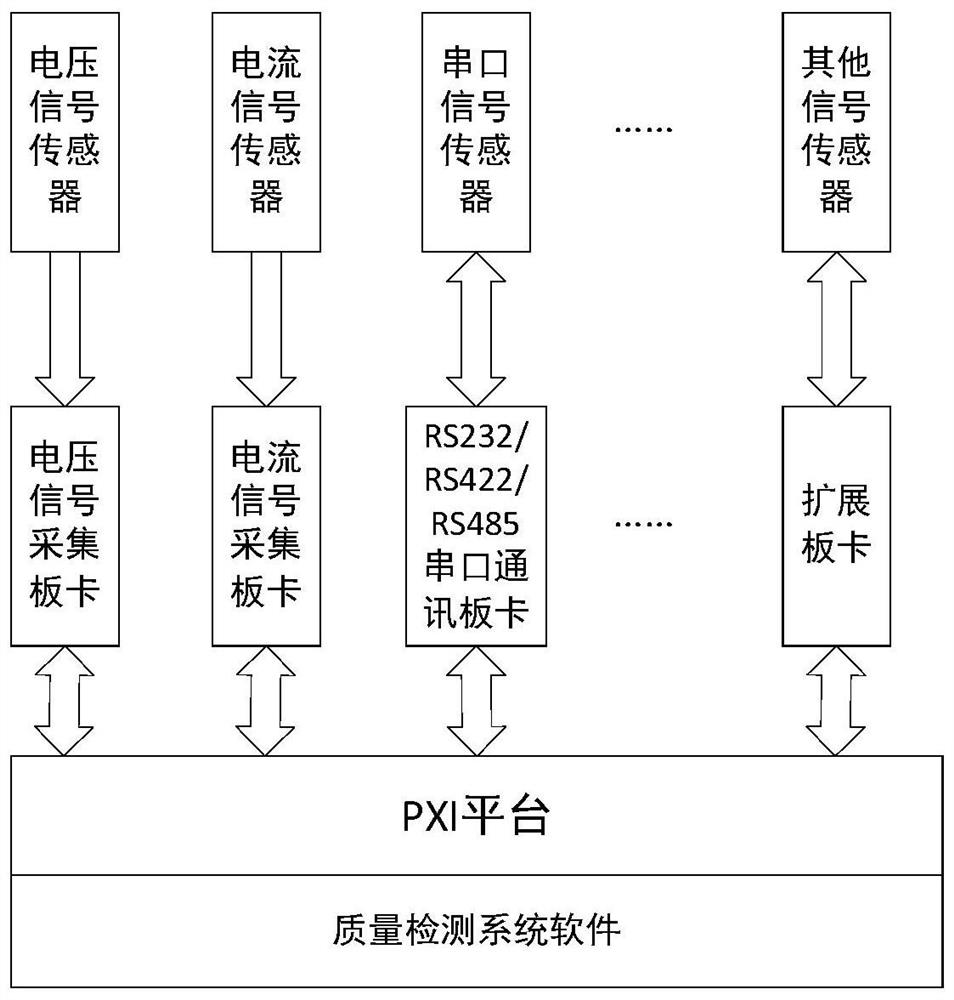

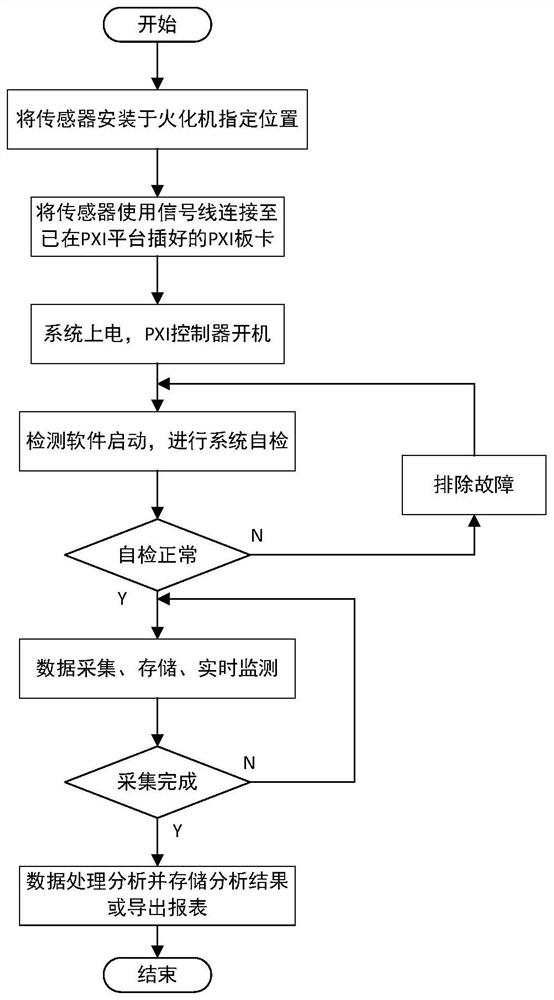

[0030] The inventive principle of the present invention is: based on the high-efficiency calculation of the PXI platform and the ability to facilitate expansion, by configuring PXI boards of various signal types, different types of sensors are integrated to realize the unified collection and centralized data processing of cremation machine quality data At the same time, using the expansion capability of the PXI platform, boards and sensors can be added or subtracted to adapt to the quality inspection of different types of cremation machines at present and in the future, so as to realize the versatility of the inspection system.

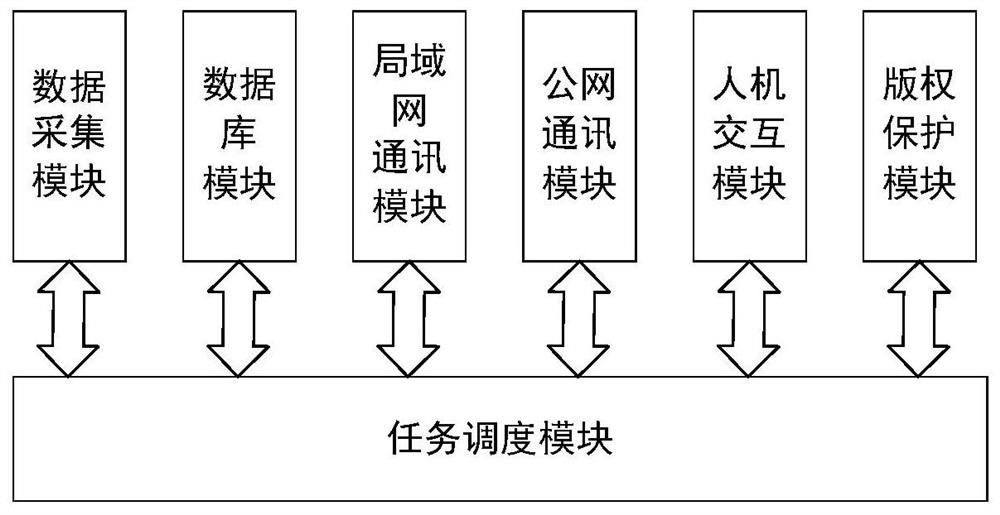

[0031]The system of the present invention includes a PXI platform, a PXI board, and a variety of commonly used sensors, wherein the sensor is installed at a position designated by the cremation machine to collect relevant data, and sensors of different signal types are connected to corresponding PXI boards and upload the collected data ;PXI platform is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com