LSTM-based optical cable manufacturing equipment fault remote prediction system

A technology for manufacturing equipment and prediction systems, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as non-stationarity, nonlinearity, and difficult model fitting of prediction sequences, etc., to improve tolerance and response ability, realize long-term memory, and improve the efficiency of fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the patent of the present invention is described below in conjunction with accompanying drawing. It should be understood that the specific implementation manners described here are only used to explain this invention patent, and are not limited to the present invention.

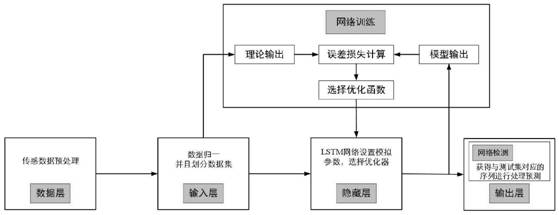

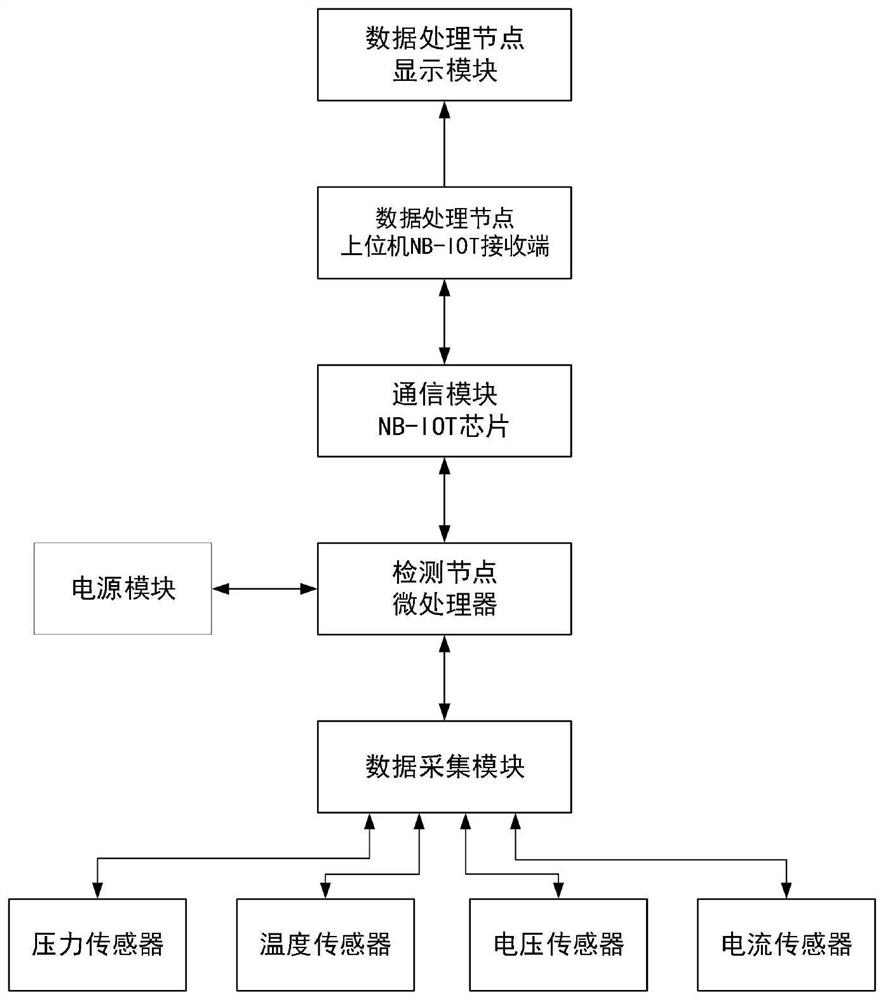

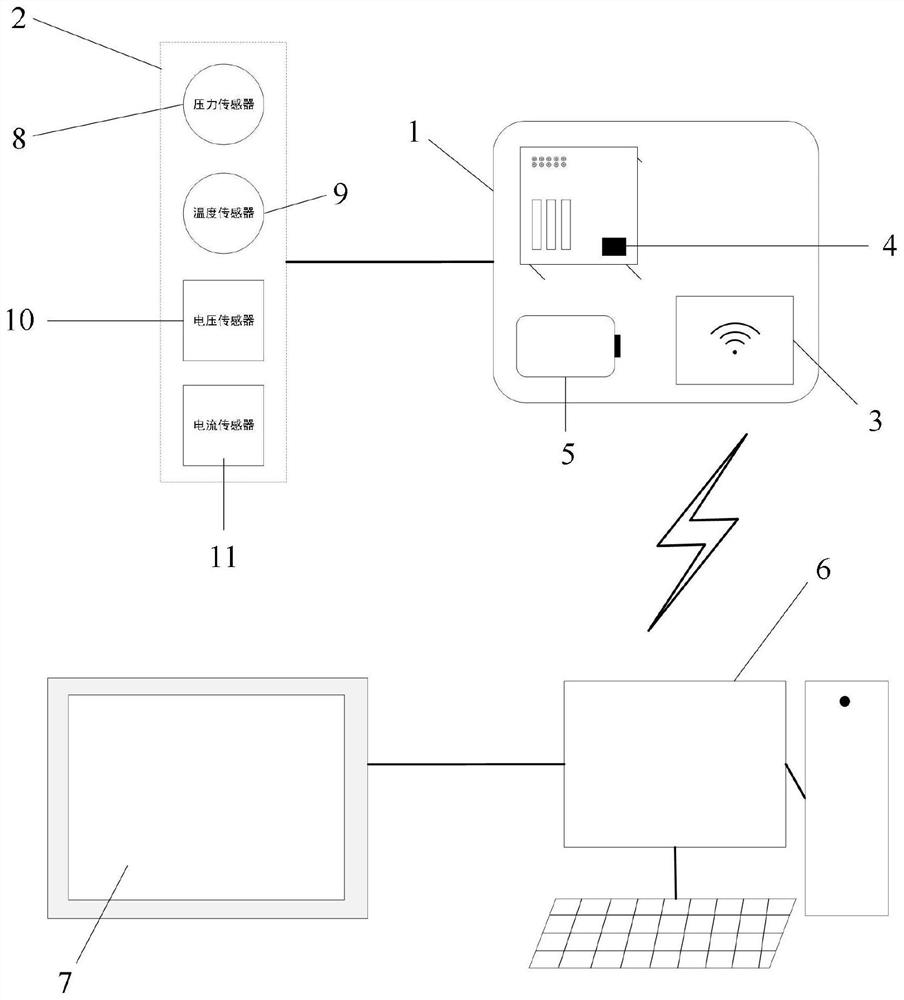

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the LSTM-based optical cable manufacturing equipment fault remote prediction system of the present invention is made up of the following parts:

[0024] The system includes detection nodes and data processing nodes. The detection node includes a microprocessor 1 , a data acquisition module 2 , a communication module 3 , an analog-to-digital conversion module 4 , and a power supply module 5 ; the data processing node includes: a host computer 6 and a display module 7 .

[0025] In the detection node, the power module 5 supplies power to the microprocessor 1 and the data acquisition module 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com