Wind tunnel operation fault diagnosis system based on distributed architecture

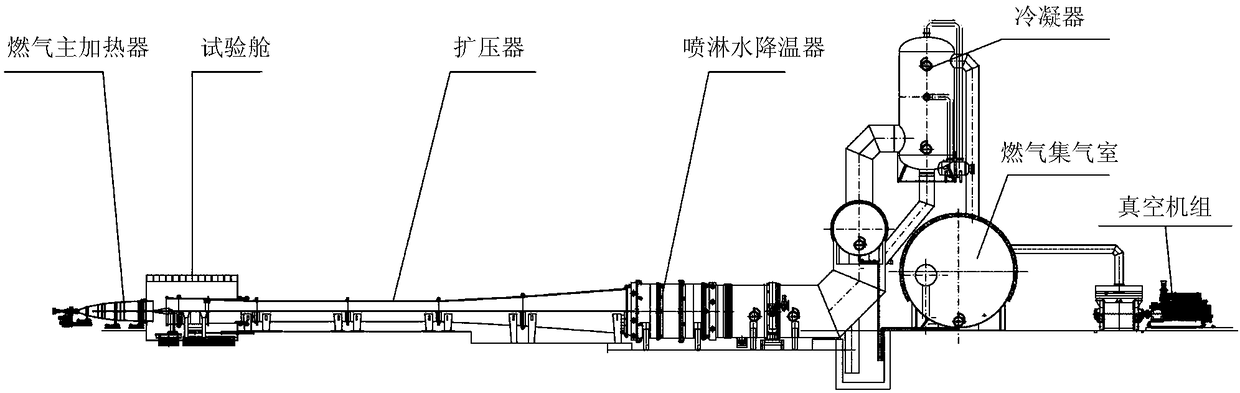

A distributed architecture and fault diagnosis technology, applied in the testing, measuring devices, instruments, etc. of machine/structural components, which can solve the problems of the gas main heater being easily burnt out in an instant, the equipment layout being scattered, and the loss etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

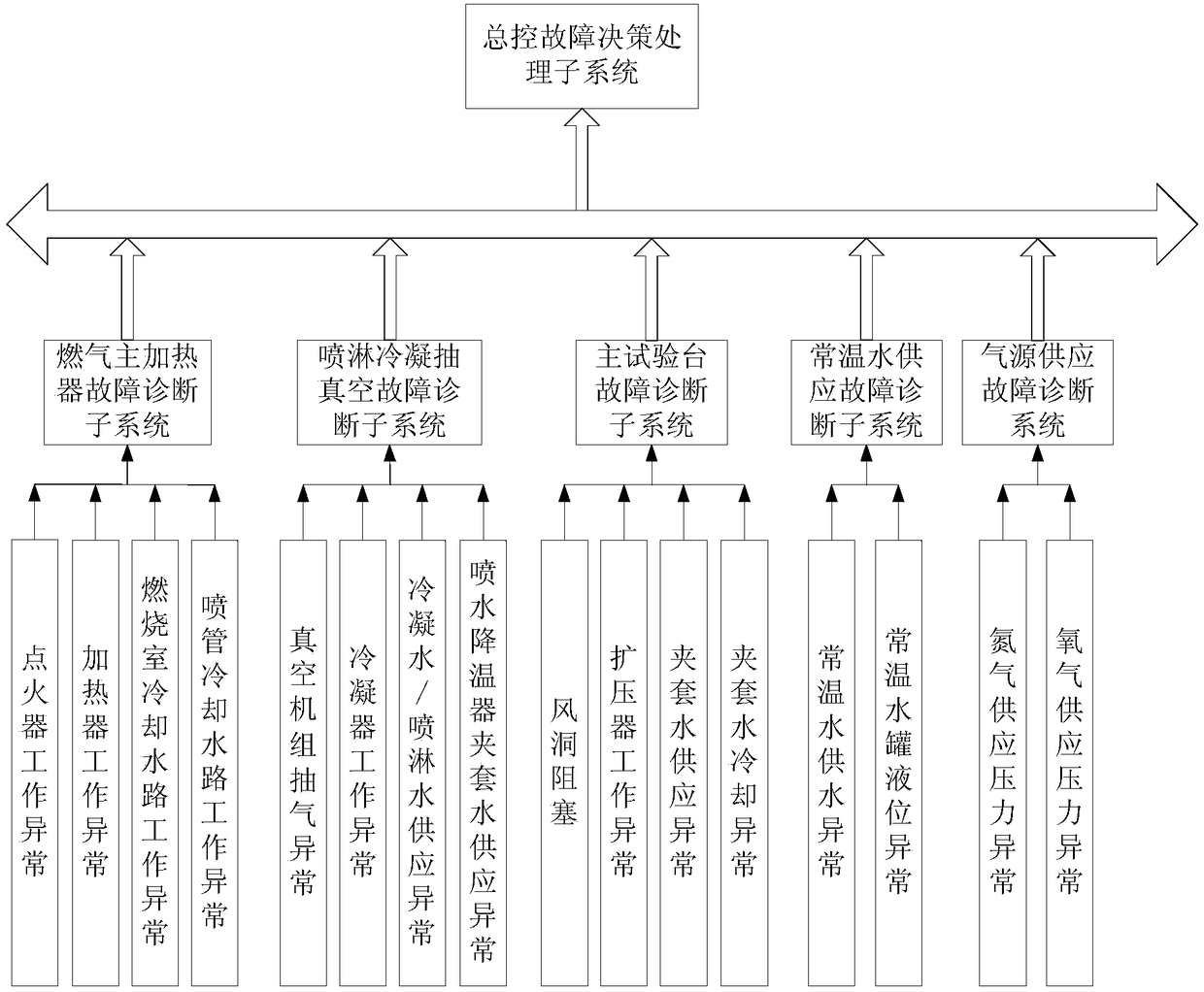

Method used

Image

Examples

Embodiment 1

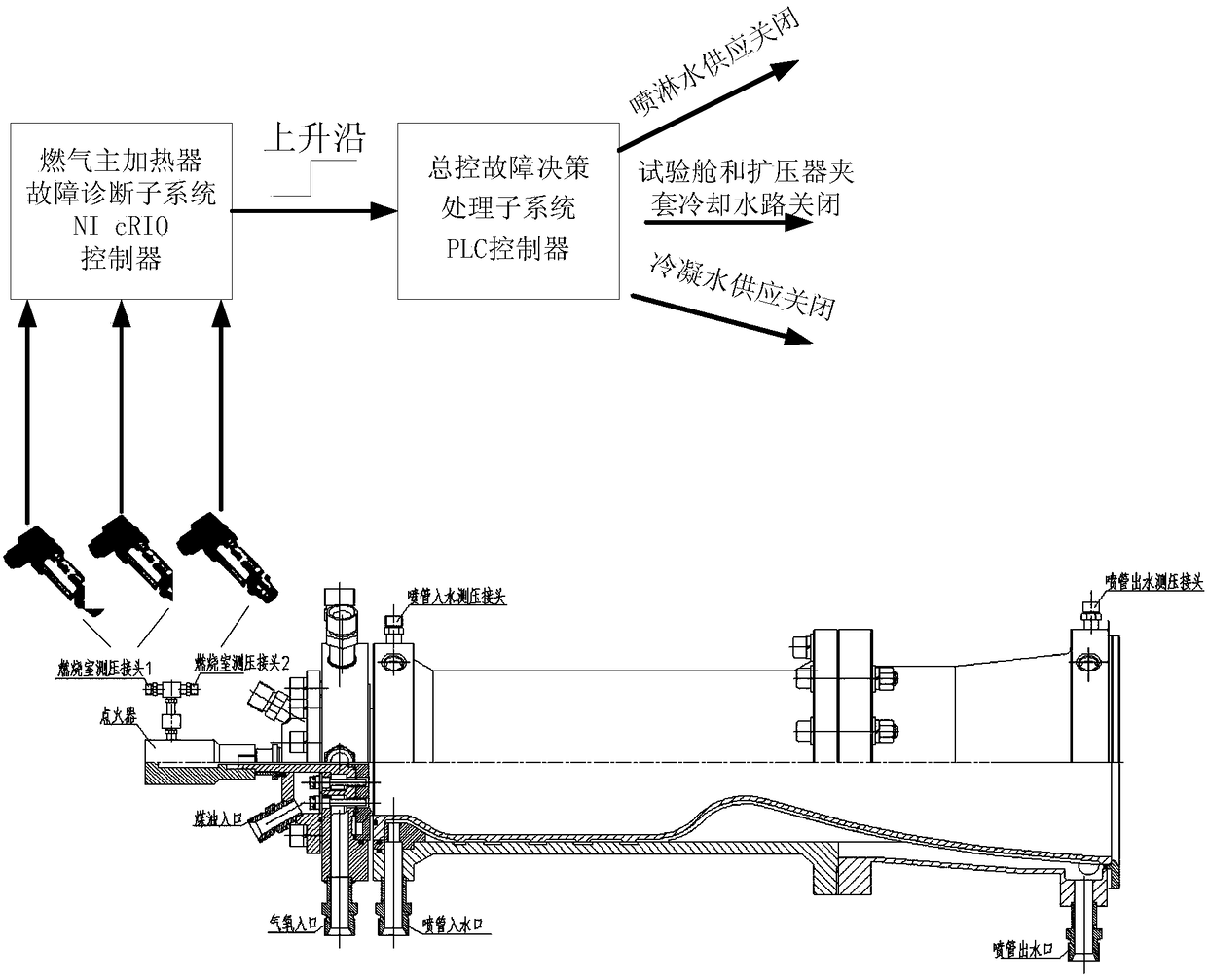

[0097] Example 1: The abnormal operation of the main gas heater triggers the shutdown of the wind tunnel

[0098] As the source of high-temperature gas production, the gas main heater plays a vital role. This embodiment adopts a two-stage ignition method in which the torch igniter ignites the heater. Press high-pressure, small-flow gas, oxygen, and kerosene into the igniter for mixed combustion according to a certain ratio and action sequence. After the ignition is stable, the condition 0.8×P is met. 点火器额定 ≤P 点火器 ≤1.2×P 点火器额定 At this time, a large flow of gas, oxygen and kerosene are pressed in from the oxygen inlet and oil inlet of the heater respectively under high pressure, fully mixed and combusted in the combustion chamber, and a high-temperature supersonic gas flow field is generated through the aerodynamic action of the nozzle, and then the condition 0.8 is satisfied. ×P 加热器额定 ≤P 加热器 ≤1.2×P 加热器额定 , 0.8×P 燃烧室水额定 ≤P 燃烧室水 ≤1.2×P 燃烧室水额定 , 0.8×P 喷管水额定 ≤P 喷管水 ≤1.2×P...

Embodiment 2

[0100] Example 2: An abnormality in the jacket cooling water supply of the main test bench triggers an alarm and shutdown of the wind tunnel

[0101] The main test bench consists of two parts: the test cabin and the diffuser. After the heat-proof structure test piece has undergone thermal assessment in the test cabin, the high-temperature gas is discharged to the rear-end spray condensation vacuum equipment through the deceleration and pressurization of the diffuser. Therefore, the water cooling and heat protection requirements of the main test bench are very high, and sufficient cooling water supply must be ensured, otherwise the equipment may be damaged. Satisfy P during the test 试验舱 试验舱高限 ,P 试验舱 ≤P 扩压器 , F 夹套水二级低限 夹套水 夹套水二级高限 , T 夹套出水 夹套出水高限 Continue the test until the set test time is reached, otherwise, a secondary fault alarm signal will be sent to the general control fault decision-making processing subsystem, and if it is more serious, it will directly trigger the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com