Composite current collector of lead-acid storage battery and battery

A lead-acid battery and current collector technology, applied in lead-acid batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of high resistance, large specific gravity, and unsatisfactory conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

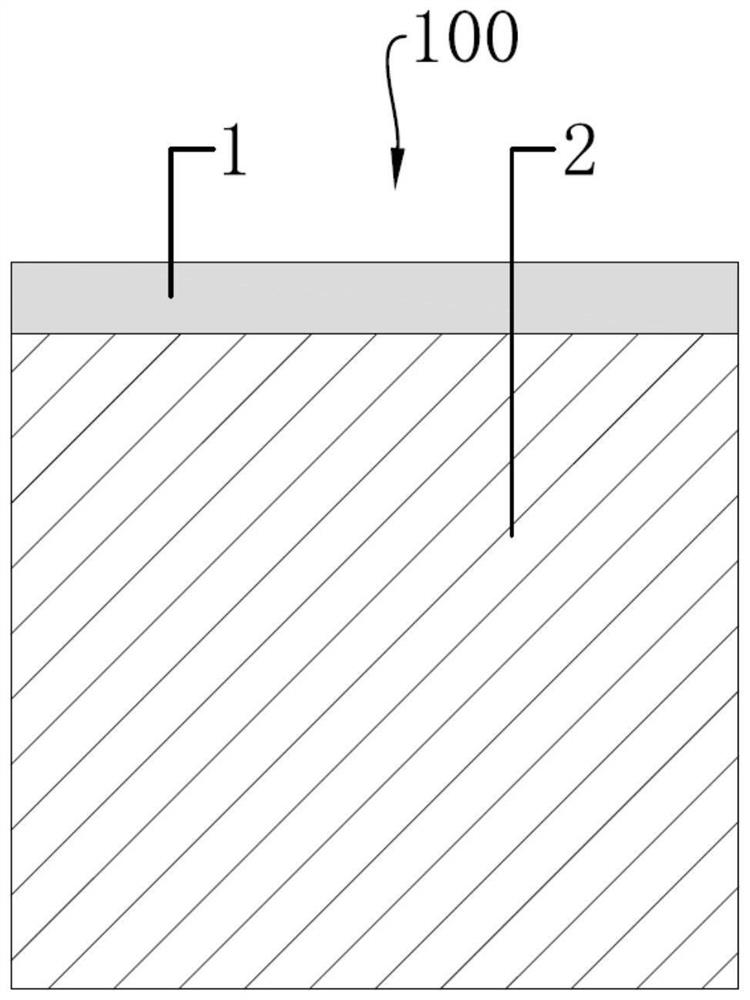

[0061] The lead-acid storage battery composite current collector of this embodiment, such as figure 1 As shown, it includes a lead skin 1 and a carrier 2. The lead skin 1 is covered on the surface of the carrier 2 and forms a stack with the carrier 2. In the stack, one surface of the lead skin 1, that is, The lower surface is in contact with or / and connected to the surface of the covered carrier 2, and the carrier 2 plays the role of mechanical bearing, support, fixation, and skeleton support for the lead skin 1; the above-mentioned formation is a two-layer laminate.

[0062] The lead or material of the lead skin 1 is 1# lead in industry, or electrolytic lead, and its lead purity is 99.994wt.%.

[0063] The carrier 2 is a polyethylene plastic plate;

[0064] The lead skin is processed through physical and mechanical processes such as casting, rolling, pressing, rolling, punching, drawing, cutting, cutting and shearing.

[0065] The lead skin 1 is a cuboid with a size of 10 m...

Embodiment 2

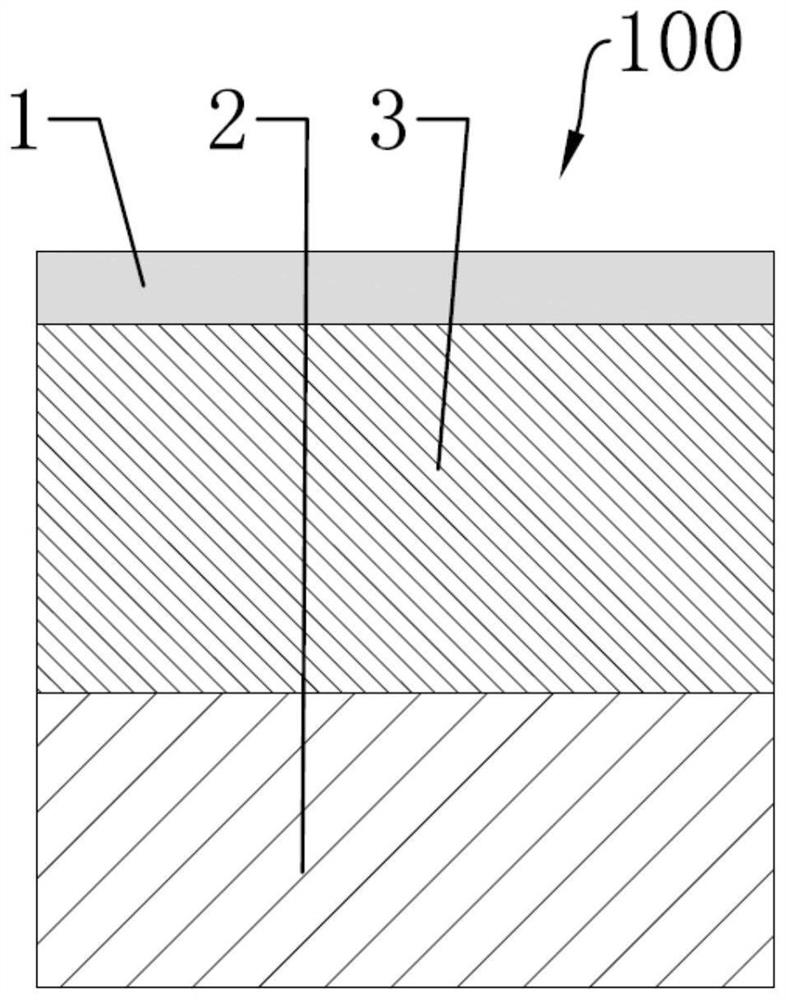

[0079] The lead-acid battery composite current collector of this embodiment includes a lead alloy skin 1 , a carrier 2 , and a lightweight conductor 3 .

[0080] The first embodiment of the lead-acid battery composite current collector in this example

[0081] Such as figure 2 As shown, the lead alloy skin 1, the carrier body 2, and the light conductor 3 form a stack with each other, and the light conductor 3 is between the lead alloy skin 1 and the carrier body 2 in the stack (located between the lead alloy skin 1 and the other One side of the lower surface) and the conductive connection of the light conductor 3 and the lower surface of the lead alloy skin 1 in surface contact or / and connection and the surface contact or / and connection with the upper surface of the carrier 2, the laminate is also a lead alloy The skin 1 and the carrier 2 are stacked in indirect contact or / and connected with each other through the lightweight conductor 3 , and the stack or stack structure is...

Embodiment 2

[0132] Embodiment 2 Implementation Mode 1 Composite Current Collector Weight = the sum of the weights of the lead alloy skin 1, the carrier 2, and the light conductor 3 in the composite current collector;

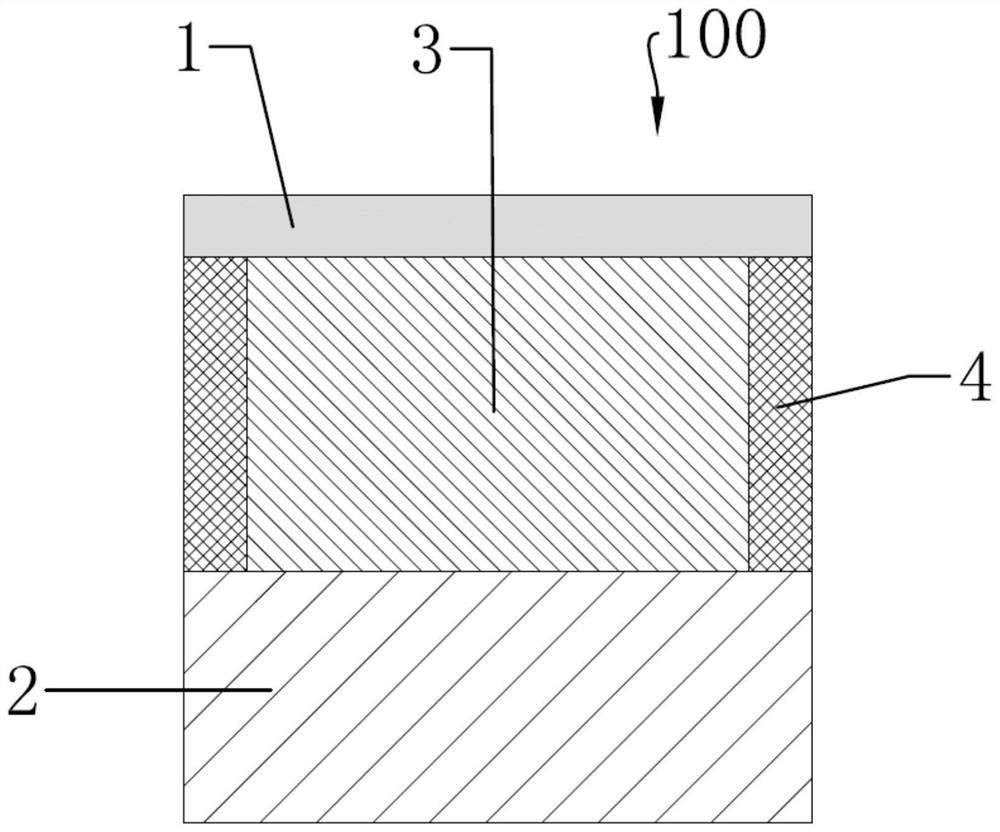

[0133] Embodiment 2 Implementation Mode 2 Composite current collector weight=the sum of the weights of lead alloy skin 1, carrier 2, light conductor 3, and edge sealing material 4 in the composite current collector;

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com