Quick locking and dismounting device for filter screen of textile machinery, and textile machinery with same

A textile machinery, fast locking technology, used in transportation and packaging, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of reduced heat dissipation performance of electric control cabinets, inconvenient cleaning and maintenance, fires, etc., to shorten the replacement time, The effect of improving work safety and stability, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

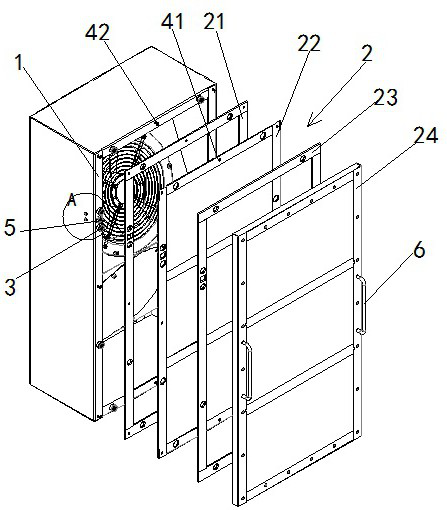

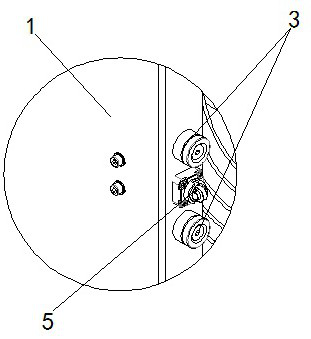

[0035] This embodiment describes a fast locking and dismantling device for a filter screen of a textile machine, such as figure 1 , figure 2 As shown, it includes a mounting frame 1 arranged on the textile machine, a filter device 2, and a magnetic part 3 that can fix part of the filter device 2 on the mounting frame 1 and remove it by magnetic force. When the filter needs to be removed When installing the filter device 2, the filter device 2 can be separated from the installation frame 1 by overcoming the magnetic force between the magnetic member 3 and the filter device 2 by hand.

[0036] It is not difficult to understand that the magnetic piece 3 is used as a locking mechanism. The magnetic part 3 can adsorb the filter device 2 on the installation frame 1 of the textile machine, and only under the action of an external force can the filter device 2 be separated from the installation frame 1, which is convenient for quick detachment. This structure can ensure that the fil...

Embodiment 2

[0043] This embodiment provides a textile machine, which includes several spinning stations arranged side by side and an electric control cabinet arranged on the machine head, and also includes the filter screen quick locking and removal device as described in Embodiment 1, and the electric control cabinet One side of the filter screen is the installation frame 1 for installing the filter screen. The quick release structure of the filter screen of the present invention, since the filter device and the mounting frame adopts magnetic locking, such a structure can ensure fast fixing and quick disengagement between the filter device and the mounting frame, and can ensure that the filter device can be quickly disassembled. Therefore, it is more convenient to clean or replace, and the workers can operate with bare hands, which greatly improves the maintenance efficiency. In this way, it can also ensure that the textile machinery with the above-mentioned filter screen quick locking a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com