Can making device for metal can

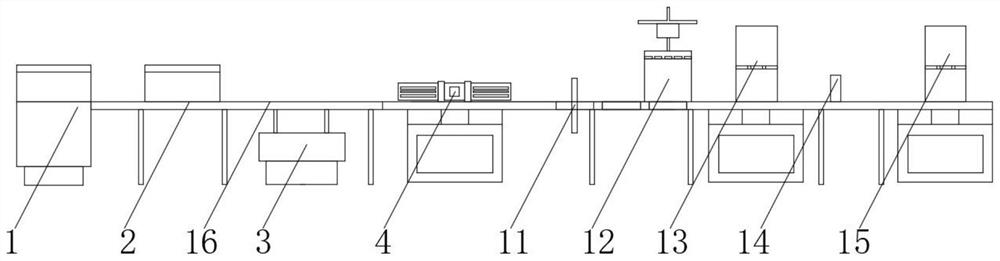

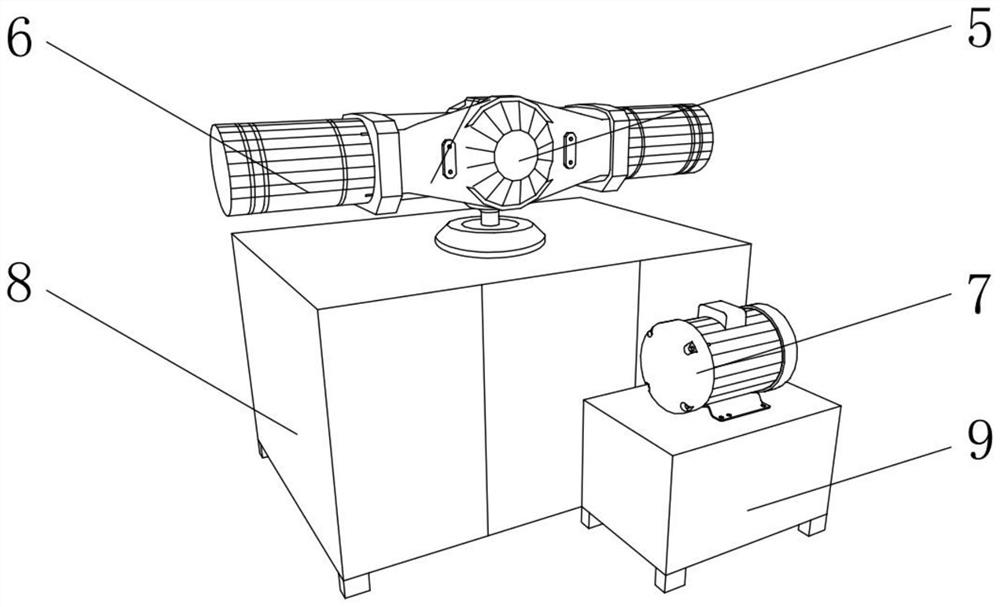

A technology for can making and metal cans, applied in the field of cans for metal cans, can solve problems such as low efficiency, affecting production efficiency and productivity, complicated machinery and equipment, etc., and achieve the effect of simplifying the processing process and improving work efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

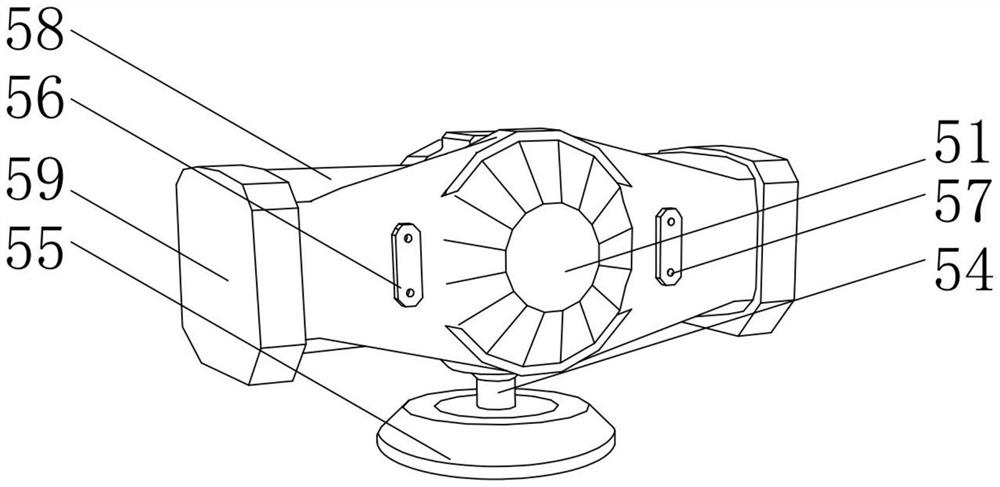

[0036] As an embodiment of the present invention, the expansion cone expansion drive assembly 10 includes a cylinder 101, a connecting shaft 102, a piston telescopic rod 103, a return spring coil 104, an expansion block 105, an expansion block 106, and a protective cover 107 And the base 108, the outer surface of the front end of the cylinder 101 is fixedly connected with a connecting shaft 102, the inside of the connecting shaft 102 is penetrated with a piston telescopic rod 103, and the outer surface of the front end of the piston telescopic rod 103 is movably connected with a return Spring ring 104, the outer surface of the front end of the return spring ring 104 is fixedly connected with an expansion cone block 106, and the outer surface of the expansion cone block 106 is sleeved with an expansion rib block 105, and the outer surface of the expansion cone block 106 The surface is covered with a protective sleeve 107, and the outer surface of the front end of the expansion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com