Taper hole drilling machine tool for steering knuckle arm

A steering knuckle arm, taper hole technology, applied in boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of high technical dependence of operators, reduced processing quality and processing efficiency, etc. To achieve the effect of simplifying clamping steps, improving processing efficiency and processing accuracy, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

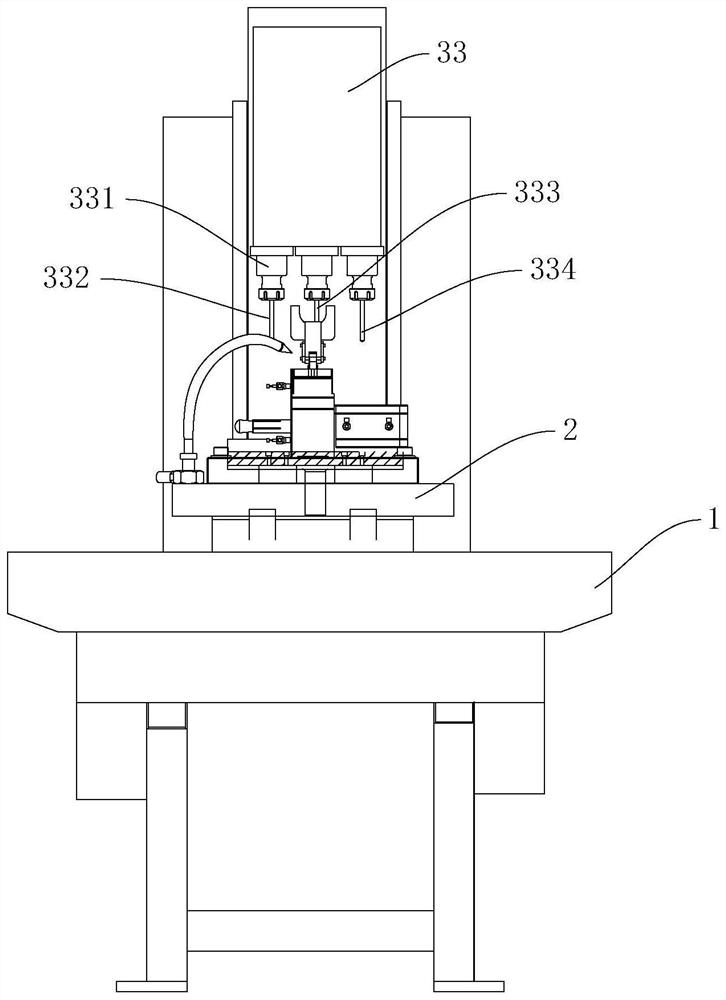

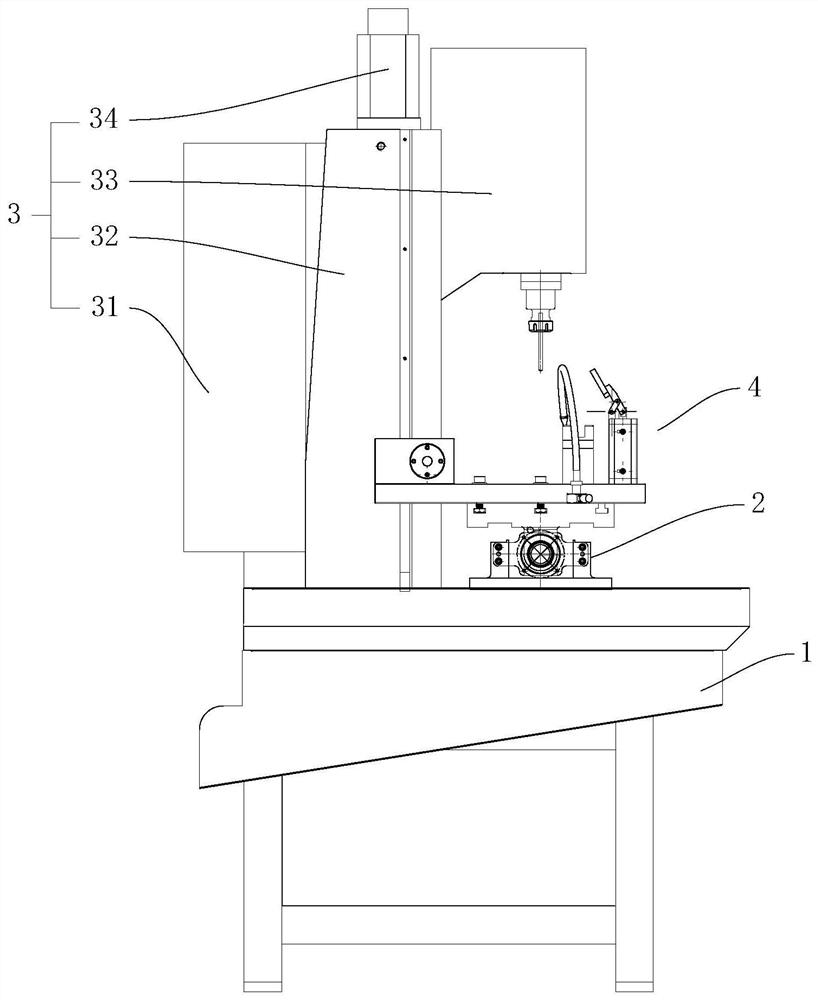

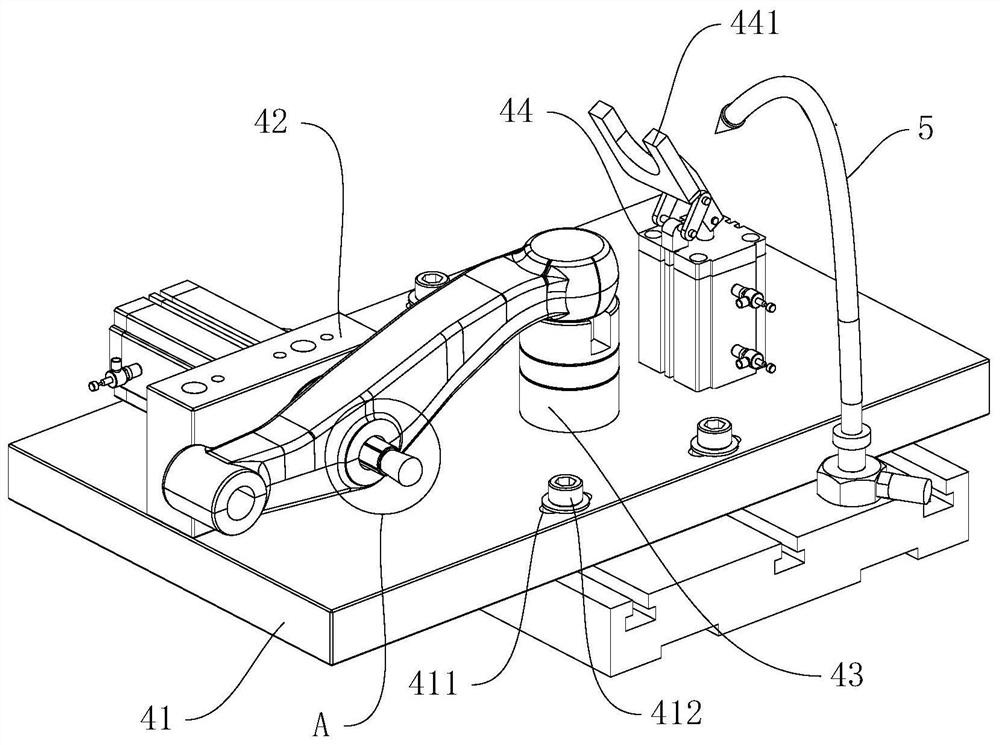

[0033] Embodiment, a kind of taper hole drilling machine tool of steering knuckle arm, such as figure 1 , figure 2 As shown, it includes a workbench 1, a tool driving device 3 provided with the workbench 1, and a servo slide 2 slidably connected to the workbench 1. The tool drive device 3 includes an electric control box 31, a column 32 vertically arranged on the workbench 1, The main shaft 331 box 33 that is slidably connected to the column 32, the servo thrust motor 4 that drives the main shaft 331 box 33 to slide along the column 32, the main shaft 331 box 33 is rotatably connected with three main shafts 331, the axis of the main shaft 331 is on the same plane, and the servo slide table 2 The sliding direction coincides with the plane where the axis of the main shaft 331 is located. The three main shafts 331 are respectively connected with a drilling bit 332, a rough reaming bit 333 and a fine reaming bit 334. The servo slide 2 is connected with a clamping assembly 4. Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com