Cutter temperature detecting and cooling device of automatic machine tool

A cooling device and tool technology, applied in positioning devices, manufacturing tools, measuring/indicating equipment, etc., can solve the problems of tool overheating, tool damage, low sensitivity, etc., and achieve the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

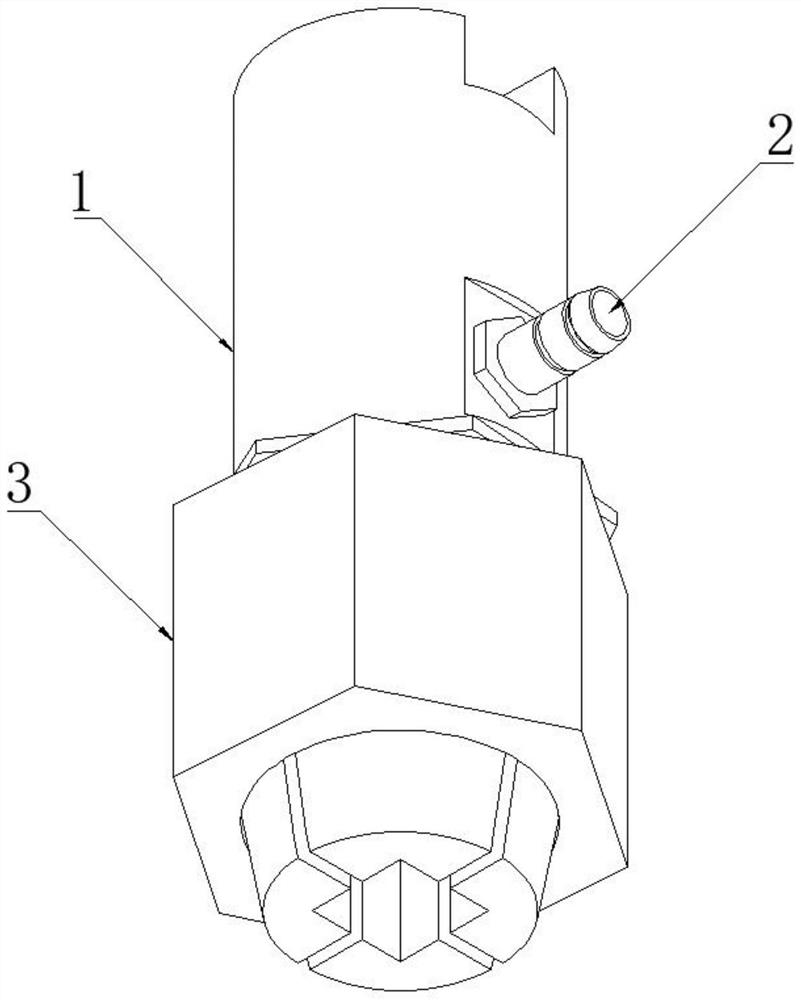

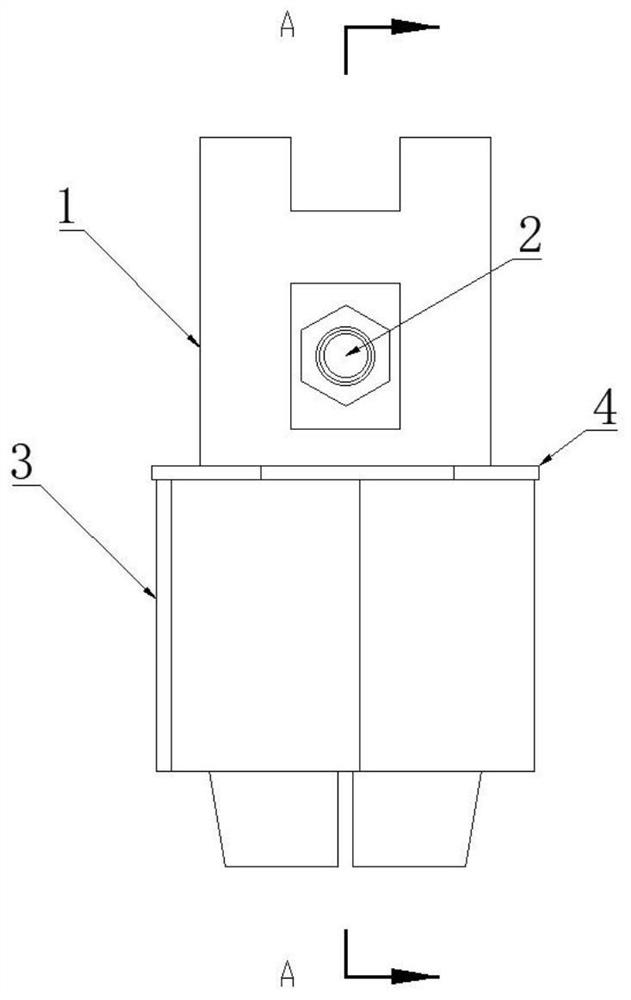

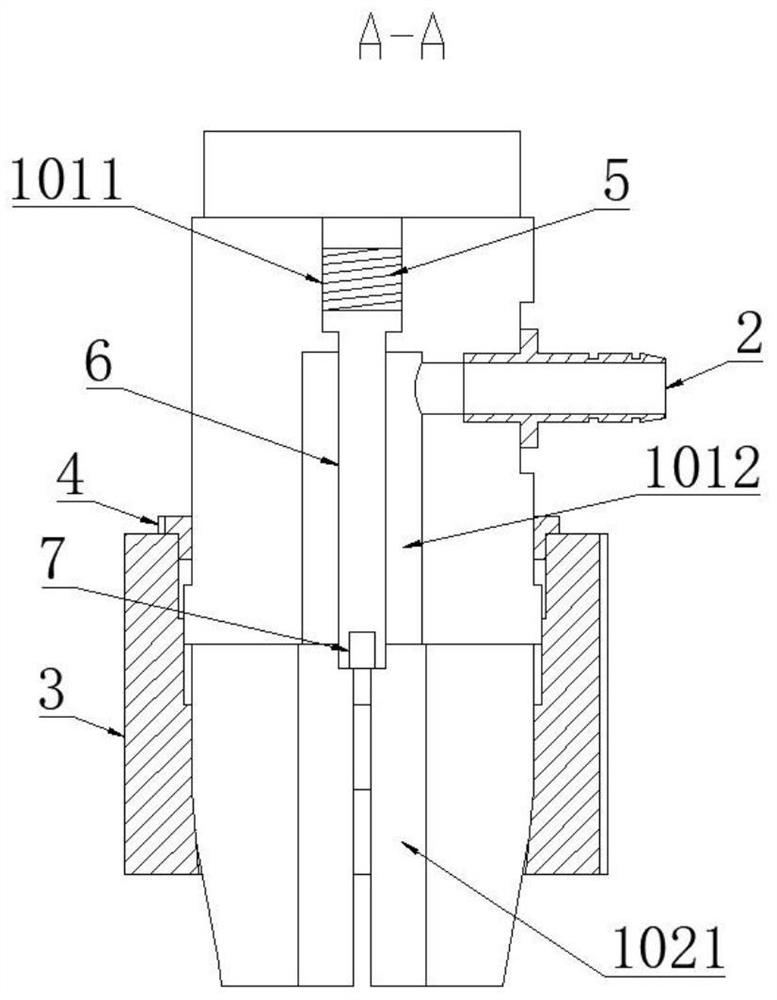

[0032] see Figure 1-5 As shown, the present invention is a tool temperature detection and cooling device for an automatic machine tool, including a fixing part 1, and the fixing part 1 includes a connecting part 101 and a mounting part 102, and a protrusion is provided on the outside of the connection between the connecting part 101 and the mounting part 102 103; the connecting part 101 is provided with diversion grooves 1012 distributed in the axial direction, and the end of the connecting part 101 is provided with deep holes 1011 communicating with the diversion grooves 1012; the installation part 102 is provided with rectangular grooves distributed in the axial direction 1021; the diversion groove 1012 communicates with the rectangular groove 1021; the ejector rod 6 is installed in the deep hole 1011, the end of the ejector rod 6 is fixed with a temperature sensor 7, and the end of the temperature sensor 7 is fixed into the rectangular groove 1021; The end face of the moun...

Embodiment 2

[0039] see Figure 1-4 , 6, the present invention is a tool temperature detection and cooling device for an automatic machine tool, including a fixture 1, and the fixture 1 includes a connecting part 101 and a mounting part 102, and the outside of the connection between the connecting part 101 and the mounting part 102 is provided with Protrusion 103; the connecting part 101 is provided with guide grooves 1012 distributed in the axial direction, and the end of the connecting part 101 is provided with deep holes 1011 communicating with the guide grooves 1012; the installation part 102 is provided with axially distributed Rectangular groove 1021; diversion groove 1012 communicates with rectangular groove 1021; ejector rod 6 is installed in deep hole 1011, the end of ejector rod 6 is fixed with temperature sensor 7, and the end with temperature sensor 7 is fixed into rectangular groove 1021 at the same time Inside; the end surface of the installation part 102 is provided with a n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap