Robot terminal load mass detection method and device and industrial robot

A quality detection method and detection device technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of increasing the cost of robots and reducing the flexibility of robots, and achieve the effect of reducing design costs and increasing available space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

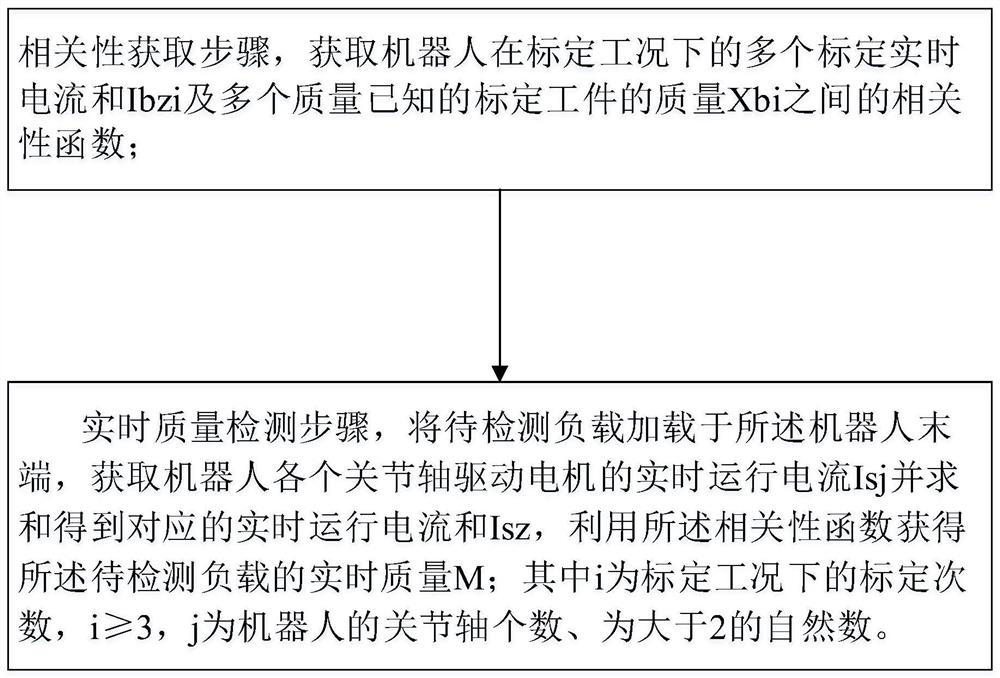

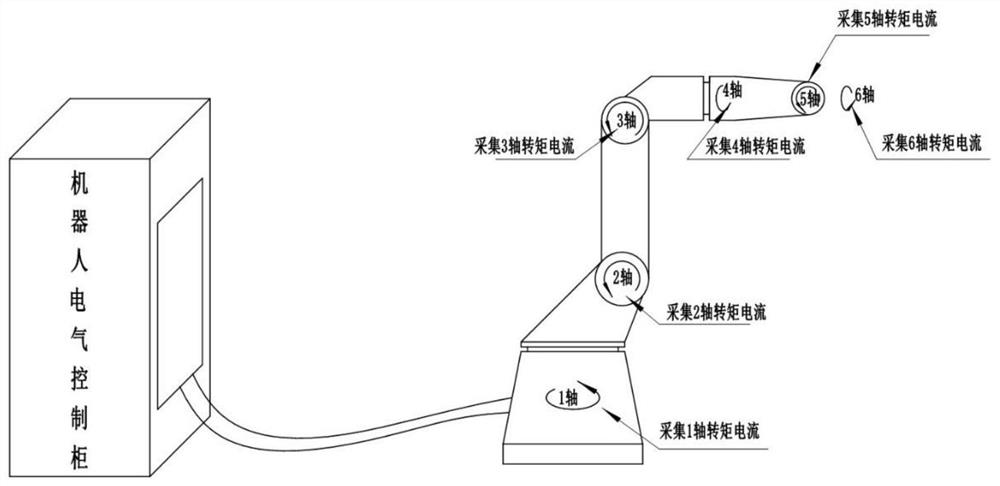

[0027] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present invention, a method for detecting the load quality of a robot end is provided, including:

[0028] The correlation acquisition step is to obtain multiple calibration real-time currents and Ibzi (that is, Figure 5 Q in ) and the mass Xbi of a plurality of calibration workpieces with known mass (that is, Figure 5 The correlation function between Xg) in ;

[0029] The real-time quality detection step is to load the load to be detected on the end of the robot, obtain the real-time running current Isj of the drive motors of each joint axis of the robot and sum them to obtain the corresponding real-time running current and Isz, and use the correlation function to obtain the waiting Detect the real-time quality M of the load;

[0030] Where i is the number of calibrations under calibration conditions, i≥3, and j is the number of joint axes of the robot, which is a natural number g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com