Excessive glue cleaning device for integrated circuit board processing

A technology for integrated circuit boards and cleaning devices, applied in circuits, metal processing equipment, electrical components, etc., can solve problems such as overflowing glue, increase product scrap rate, increase circuit board damage, etc., to reduce defective products and reduce labor intensity. , the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

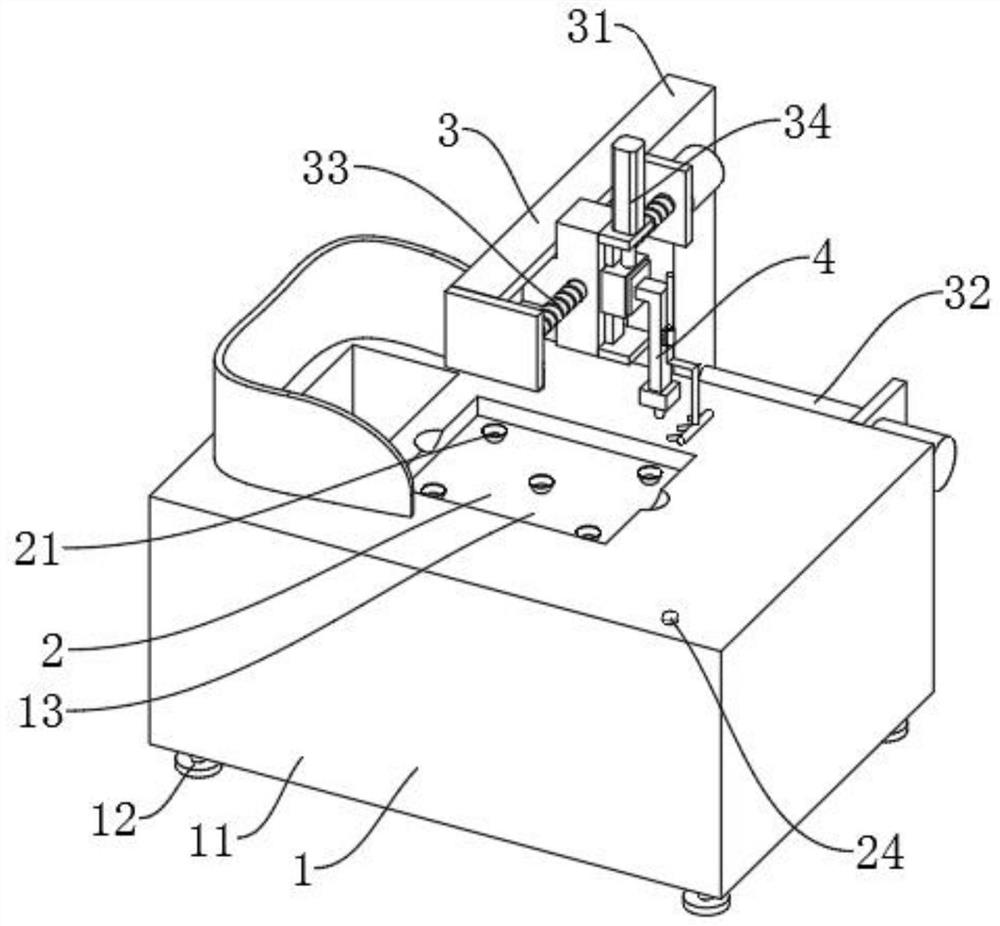

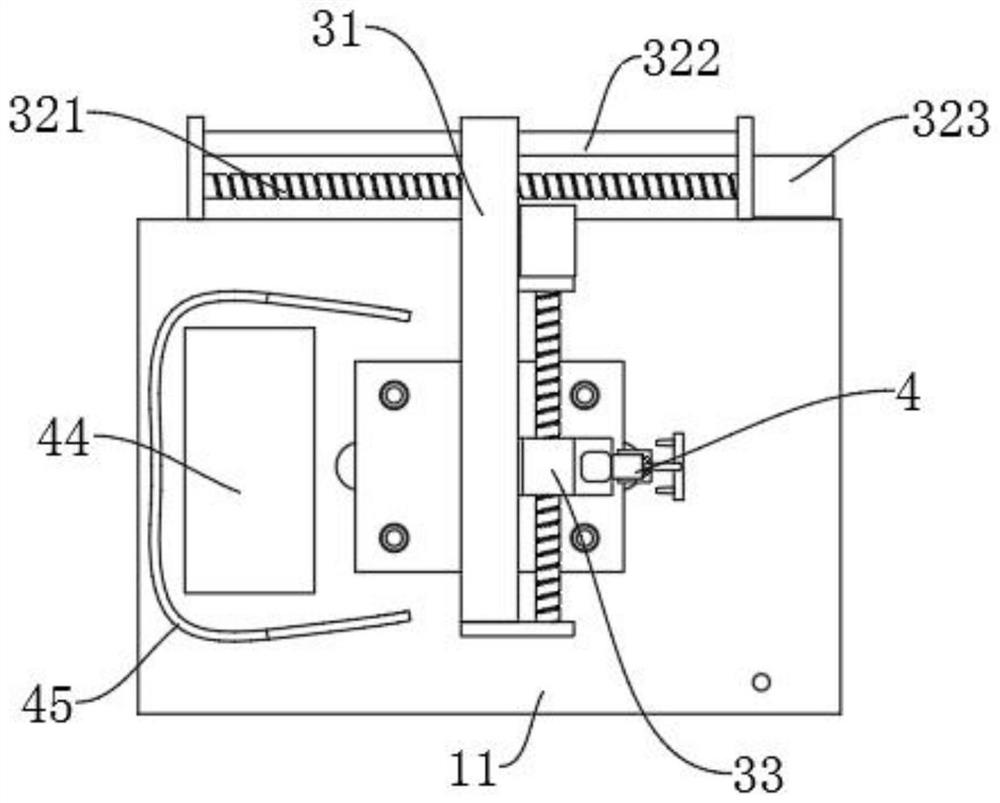

[0046] Such as Figure 1-Figure 6 As shown, a glue overflow cleaning device for integrated circuit board processing includes a supporting mechanism 1 and a fixing mechanism 2 arranged on the supporting mechanism 1 for fixing the circuit board. The glue mechanism 4, and the steering mechanism 3 that is provided with the glue removing mechanism 4 to move, the steering mechanism 3, the fixing mechanism 2 are connected with the supporting mechanism 1, and the glue removing mechanism 4 is connected with the steering mechanism 3;

[0047] The support mechanism 1 includes a box body 11, a support base 12 is provided at the corner of the lower end of the box body 11, a sinking platform 13 is provided at the upper end of the box body 11, and a fixing mechanism 2 is arranged inside the sinking platform 13;

[0048]The fixing mechanism 2 includes a suction cup 21, the lower end of the suction cup 21 is connected with an on-off valve 22 to control the on-off of the air flow, the other end...

Embodiment 2

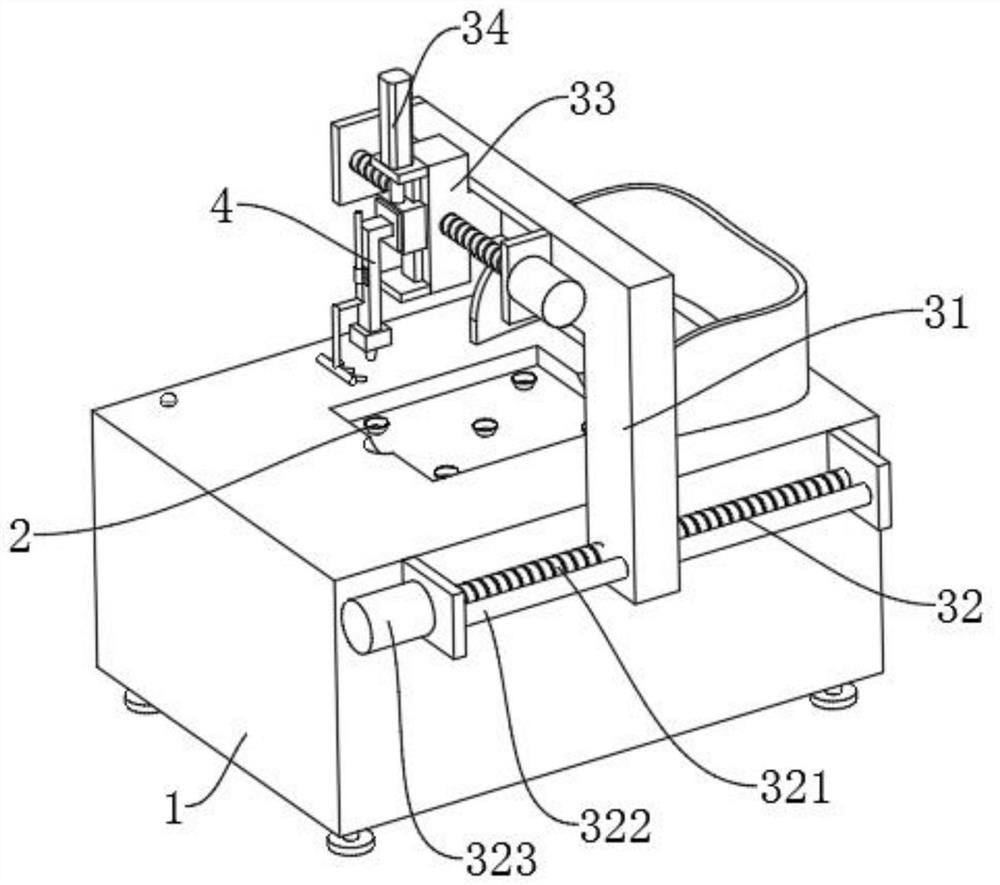

[0053] Such as Figure 7-Figure 8 As shown, a glue overflow cleaning device for integrated circuit board processing includes a supporting mechanism 1 and a fixing mechanism 2 arranged on the supporting mechanism 1 for fixing the circuit board. The glue mechanism 4, and the steering mechanism 3 that is provided with the glue removing mechanism 4 to move, the steering mechanism 3, the fixing mechanism 2 are connected with the supporting mechanism 1, and the glue removing mechanism 4 is connected with the steering mechanism 3;

[0054] The support mechanism 1 includes a box body 11, a support base 12 is provided at the corner of the lower end of the box body 11, a sinking platform 13 is provided at the upper end of the box body 11, and a fixing mechanism 2 is arranged inside the sinking platform 13;

[0055] The fixing mechanism 2 includes a suction cup 21, the lower end of the suction cup 21 is connected with an on-off valve 22 to control the on-off of the air flow, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com