Middle motor capable of realizing multi-gear variable-speed adjustment

A technology with a central motor and variable speed adjustment, which is applied in the direction of bicycle gear shifting mechanisms, vehicle gearboxes, wheel transmissions, etc., can solve problems such as inability to achieve variable speeds, achieve smooth and labor-saving riding experience, small size, reduced The effect of flat space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

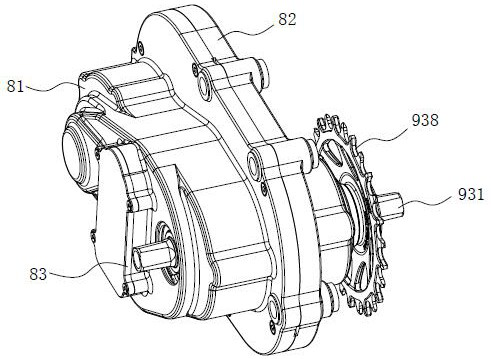

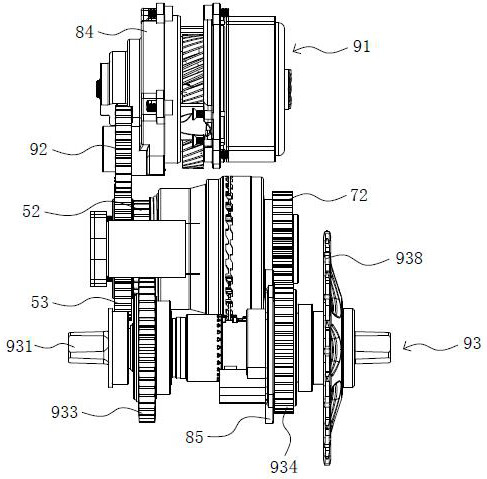

[0070] A mid-mounted motor capable of multi-speed variable speed adjustment, refer to figure 1 and figure 2 , which includes a first housing 81 and a second housing 82, the cavity formed by the first housing 81 and the second housing 82 is provided with a power-assisted driving mechanism 91, a speed change mechanism and a center shaft mechanism 93; the power-assisted driving mechanism 91, The speed change mechanism and the central axis mechanism 93 form a three-axis design, which ensures that the overall size and weight of the motor are reduced.

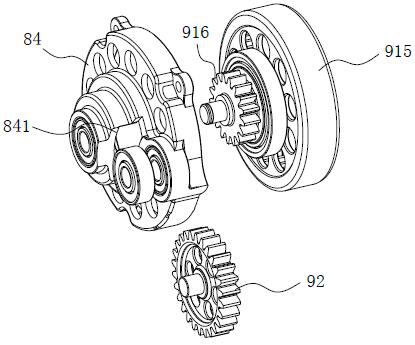

[0071] refer to figure 2 and Figure 4 , the central axis mechanism 93 includes a pedal power input assembly and a driving power output assembly, the booster drive mechanism 91 includes a booster motor 911 and a booster input assembly; The variable speed input component includes a pedal variable speed input component and an assist variable speed input component; wherein, the pedal power input component is connected with the peda...

Embodiment 2

[0118] A mid-mounted motor capable of multi-speed variable speed adjustment, refer to Figure 21 , based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that in this embodiment, the first spring 67 is sleeved on the center shaft input sleeve 51, and the gap between the first spring 67 and the transmission ring gear 62 A first plane bearing assembly 672 is provided; the first plane bearing assembly 672 includes balls, a cage and a bearing bracket, and the bearing bracket is also used as a raceway for the balls, while the balls are in contact with the outer end surface of the transmission ring gear 62; one end of the first spring 67 It is in contact with the end surface of the center shaft input gear 52, and one end is in contact with the bearing bracket, and its elastic thrust F1 is applied to the transmission ring gear 62 through the bearing bracket and the roller.

[0119] refer to Figure 22 , in this embodiment, a second plane bearing assembly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com