Manufacturing method of mems device and mems device

A manufacturing method and device technology, applied in the manufacture of MEMS devices and the field of MEMS devices, can solve the problems that the film area cannot be made larger, the contact hole cannot be made smaller, and the performance of the device is affected, so as to achieve more convenience and feasibility, form The method is flexible and the effect of improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

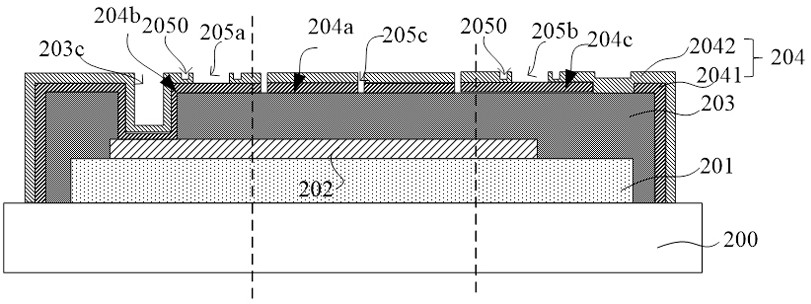

[0067] In addition, although this embodiment shows that the upper plate material layer 204 is composed of three layers, and the bottom dielectric layer 2043 is reserved at the bottom of the groove 203b, the technical solution of the present invention is not limited thereto . In other embodiments of the present invention, when the method of forming the groove 203b in the first insulating dielectric layer is used to solve the problem of electrochemical corrosion of the conductive layer 2041 below due to the infiltration of etching solution at the contact hole of the upper plate lead-out part 204c When there is a problem, as long as the upper plate lead-out portion 204c does not cause a short circuit between the upper plate 204a and the lower plate 202, the bottom dielectric layer 2043 can be omitted in the upper plate material layer 204, or the upper plate lead-out portion The conductive layer 2041 of 204c is in direct contact with the corresponding portion of the lower plate 20...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap