Unit mutual standby ozone generation device

An ozone generating device and ozone generator technology, applied in the direction of ozone preparation by discharge method, ozone preparation, oxygen/ozone/oxide/hydroxide, etc., can solve the problem of long time consumption and manpower, and low utilization rate of standby machines , uneconomical operation and other issues, to achieve the effect of narrowing the scope of investigation, shortening maintenance time, and reducing capital occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

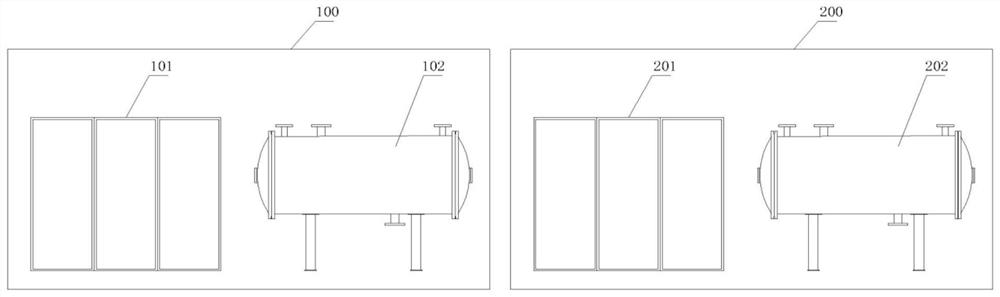

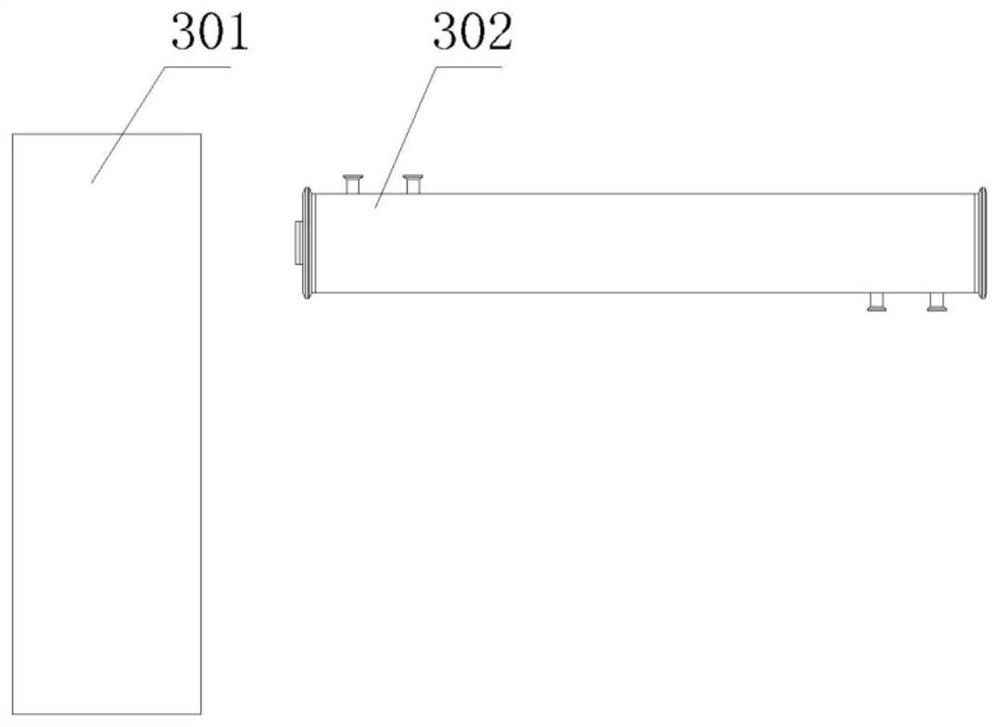

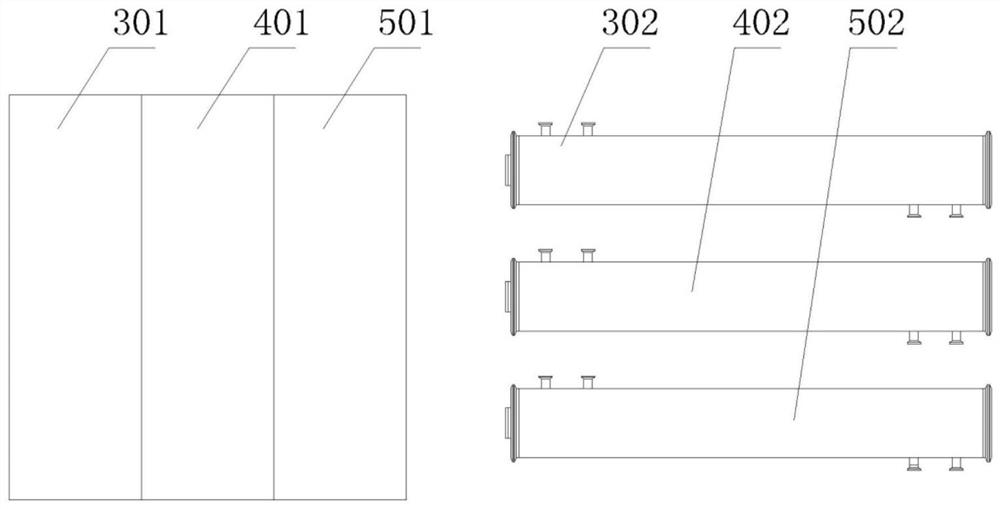

[0025] Example: as attached figure 2 to attach Figure 5 As shown, an ozone generator 600 for unit mutual use includes a skid-mounted base 601, and a first unit ozone generator, a second unit ozone generator, and a third unit ozone generator are installed on the skid-mounted base 601, and the first unit Ozone generator comprises the first unit ozone power supply 301 and the first unit ozone generating chamber 302, the first unit ozone power supply 301 is electrically connected with the first unit ozone generating chamber 302, the second unit ozone generator, the third unit ozone generator and The structure of the first unit ozone generator is the same.

[0026] One end of the first unit ozone generating chamber 302 is provided with a first raw material gas inlet valve 1 and a first cooling water outlet valve 10 , and the other end is provided with a first ozone gas outlet valve 4 and a first cooling water inlet valve 7 .

[0027] One end of the second unit ozone generating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com