Glass preparation device facilitating edge stripping

A technology for preparing devices and glass, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc. It can solve the problems of glass edge and middle broken by impact force, affect glass production output, and affect glass quality, so as to speed up shaping and avoid Condensation is too fast and the effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

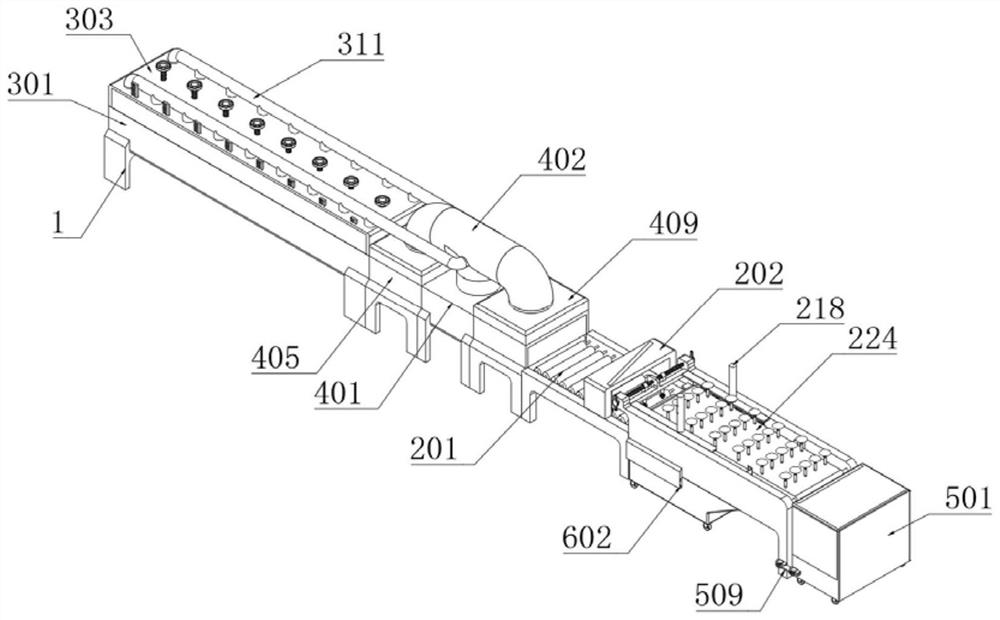

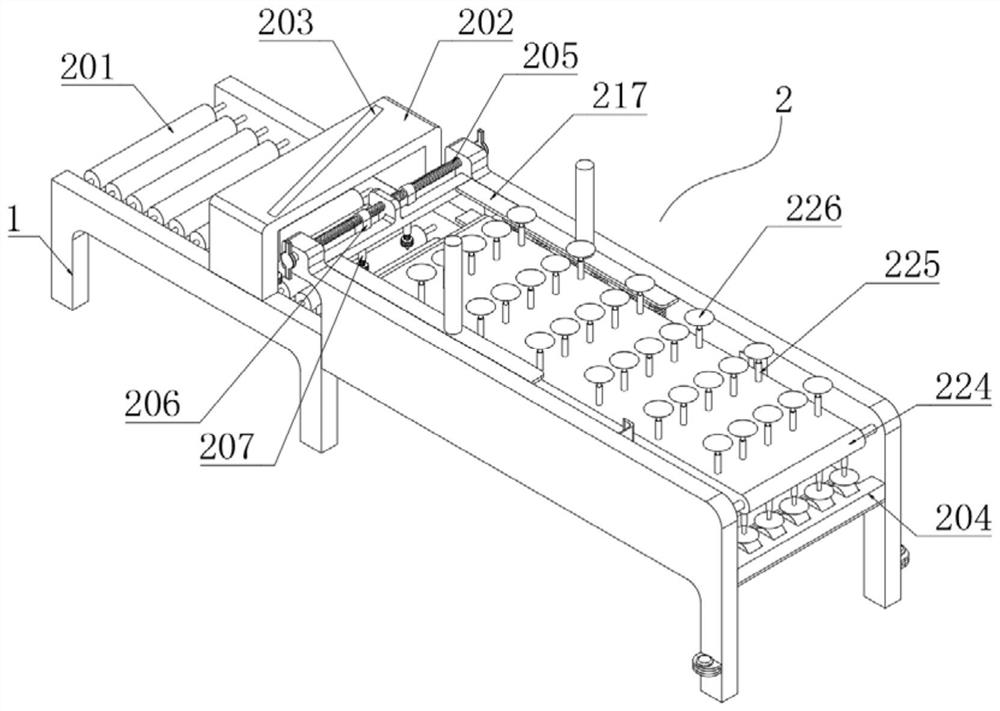

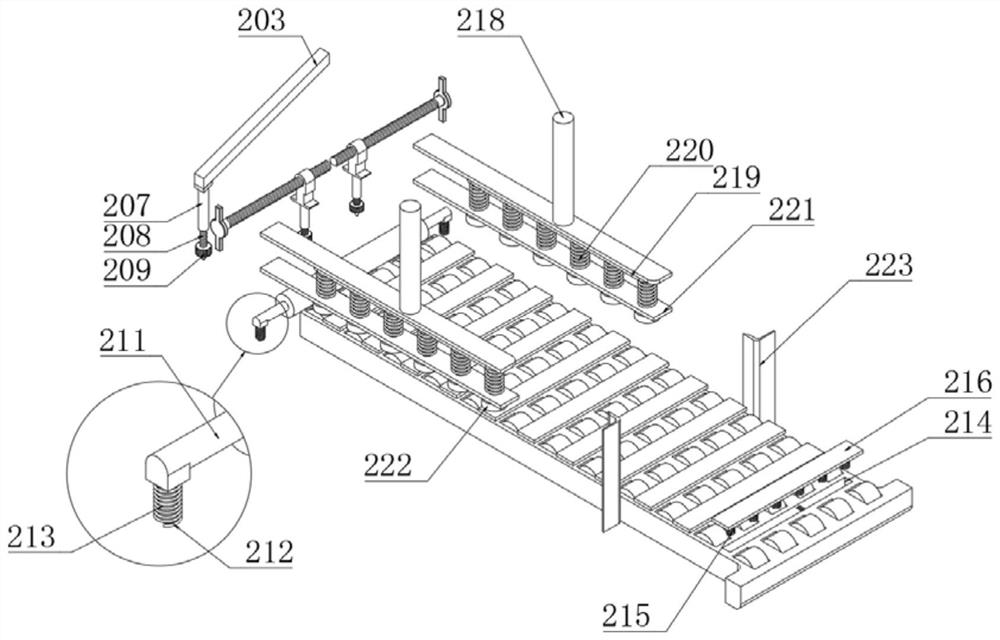

[0040] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, a glass preparation device that is convenient for edge stripping, including a support frame 1, a cutting edge stripping assembly 2 is installed on one side of the support frame 1, the glass is cut by a cutting knife 209, and the Its cutting position is adjusted so that the glass can be adjusted according to the thickness and width of the glass. At the same time, the glass after cutting is stripped through the lifting roller 211 and the rubber buffer plate 216. At the same time, the spring and the rubber pad are used to strip the edge. Protect it to avoid glass cracking caused by shaking of the glass during edge stripping;

[0041] On the side of the top of the support frame 1 away from the edge cutting and stripping component 2, a uniform forming component 3 is installed, and the temperature of the glass liquid is separated and cooled by separating the insulation board 304 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com