Hydraulic loading servo control system for output shaft of speed reducer and control method

A servo control system and hydraulic loading technology, which is applied in fluid pressure actuation system components, servo meter circuits, servo motor components, etc., can solve the problem that the oil temperature cannot be controlled within the working range, and the oil motor torque and speed control are inaccurate and other problems to achieve the effect of simple structure and preventing excessive pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

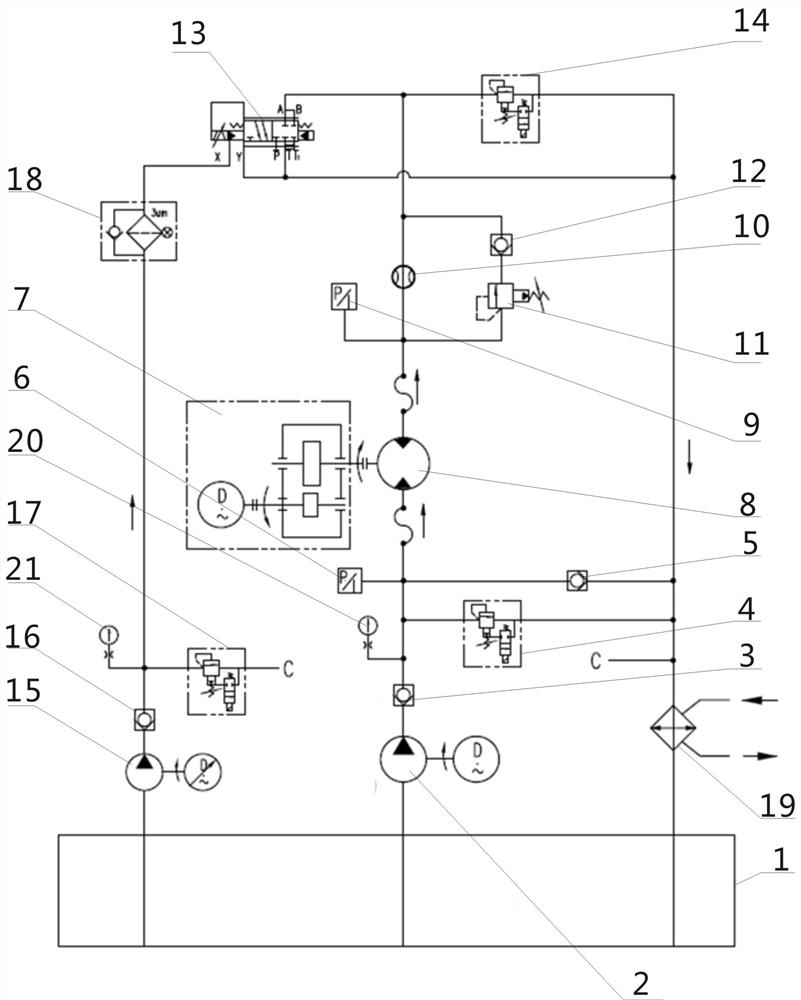

[0018] combined with figure 1 The hydraulically loaded servo control system for the output shaft of the reducer includes an oil tank 1, a pump motor unit A2, a pump motor unit B15, a test piece 7, an oil motor 8 and a cooler 19, a pump motor unit A2, and a pump motor unit B15 The oil inlets of the pumps are respectively connected to the oil tank 1, the outlet of the pump motor unit A2 is connected to the inlet of the oil motor 8 through the pipeline A, and the pipeline A is provided with a check valve A3, a pressure gauge A20 and a pressure sensor A6 in sequence, and the oil motor The output end of 8 is fixedly connected with test piece 7 through a coupling, the oil outlet of oil motor 8 is connected with the control oil port (A, B) of servo valve 13 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com