Rotor coreless magnetic pole structure and design method of a two-pole permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and magnetic pole structure, which is applied in the direction of synchronous motor with stationary armature and rotating magnet, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. The magnetic direction changes too much and the magnetic density of the yoke is high, so as to achieve the effect of simple magnetization, high sine degree and high-efficiency operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

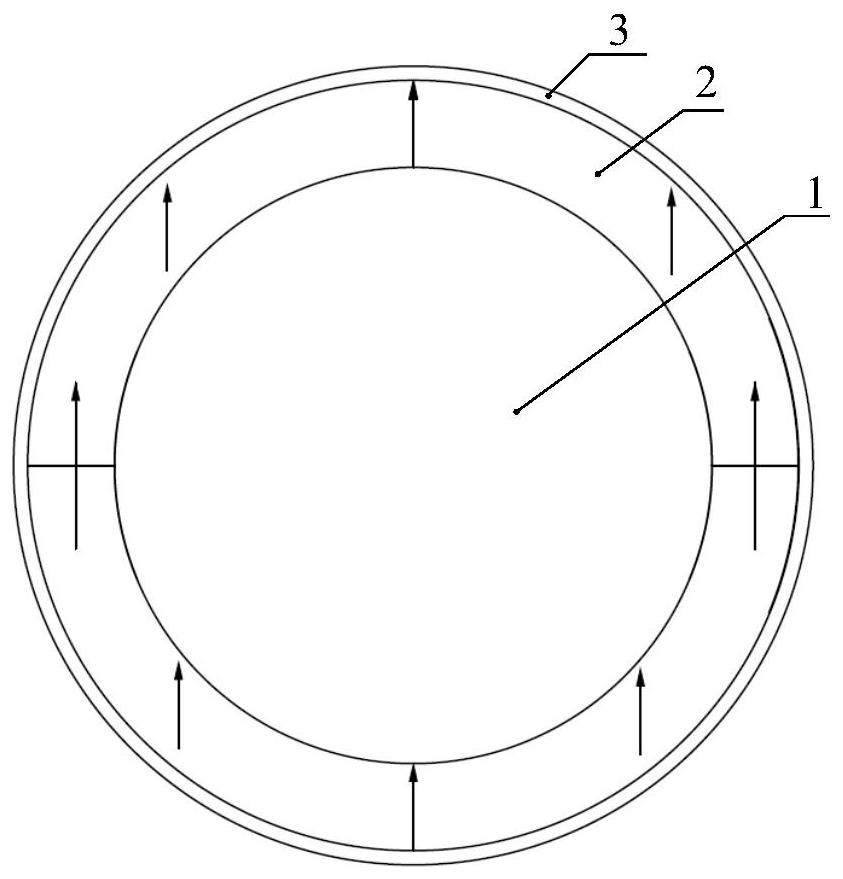

[0043] A 2-pole permanent magnet synchronous motor with a rated power of 75kW and a rated speed of 33000r / min. It is required that the outer diameter of the stator is 150mm, the length of the stator iron is 140mm, and the length of the air gap is 1.75mm. According to the design method of the present invention, it is calculated that the diameter of the titanium alloy rotating shaft is 45mm, the thickness of the permanent magnet is 6.5mm, the thickness of the protective cover is 1mm, and the outer diameter of the rotor is 60mm.

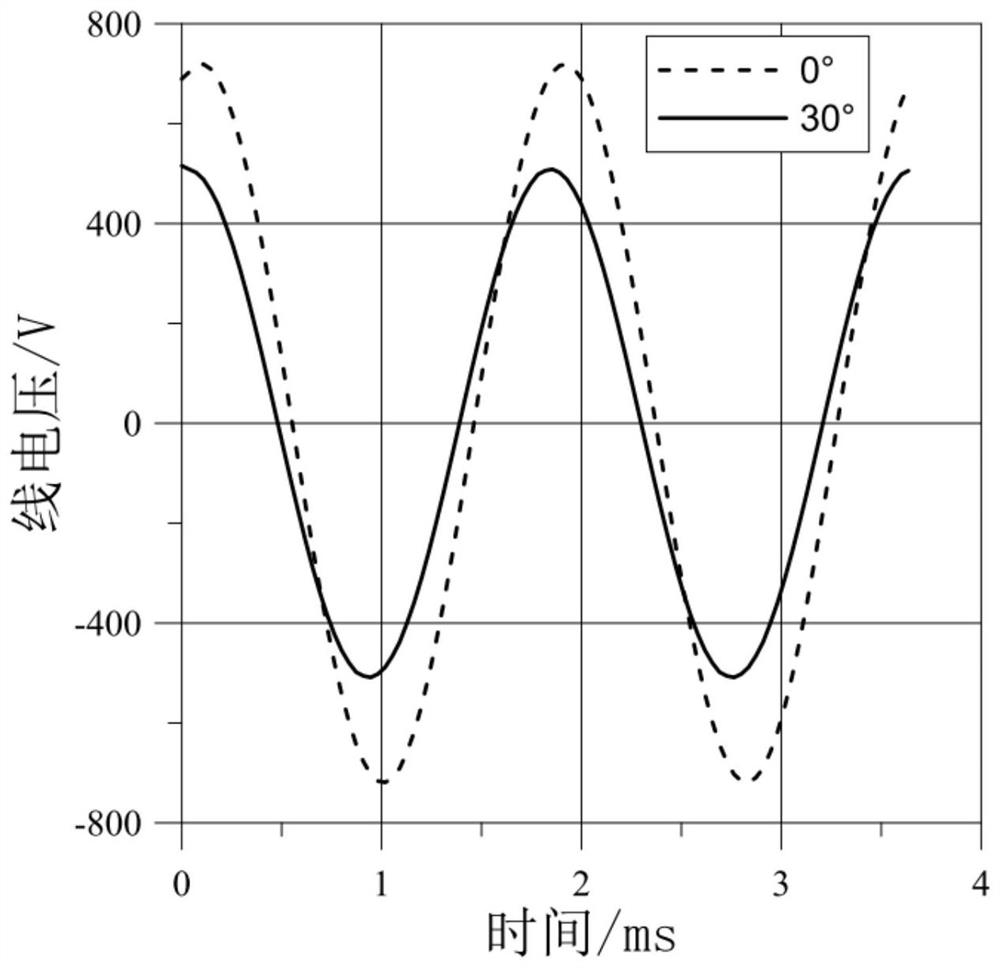

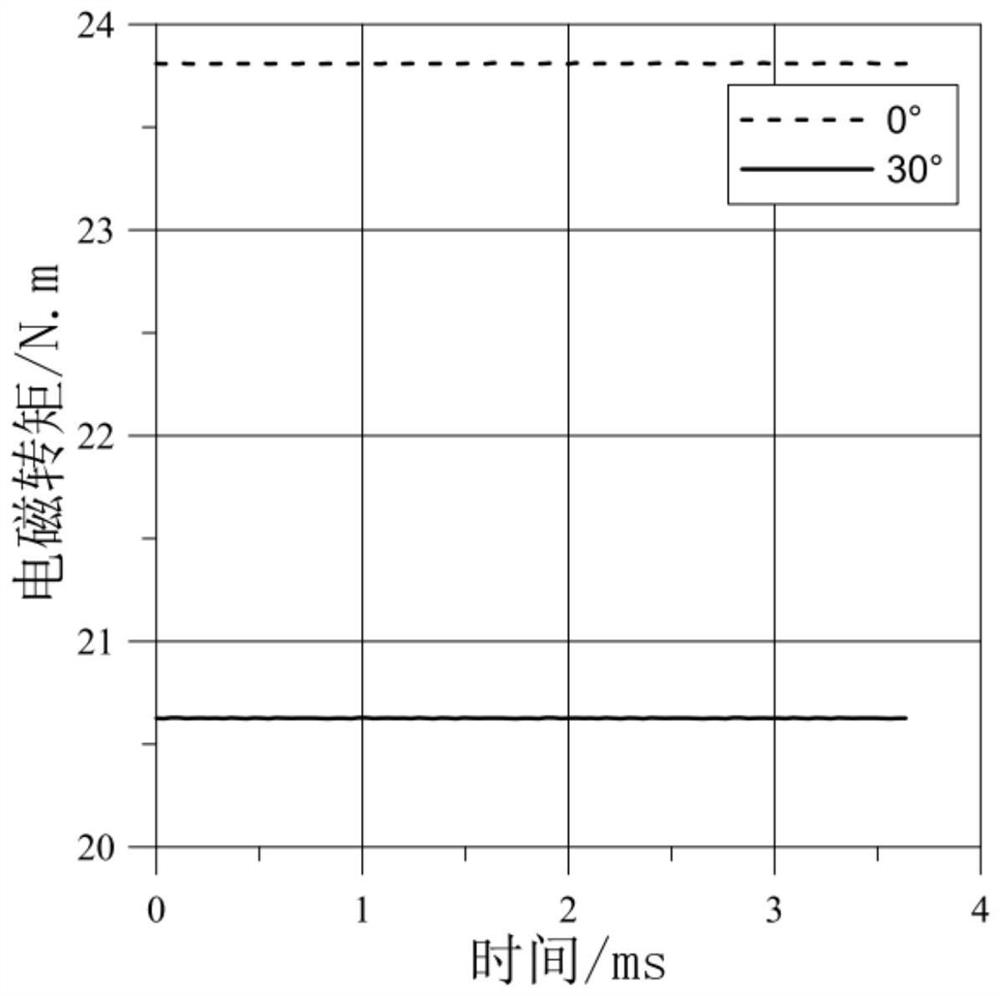

[0044] With the magnetic pole structure of the present invention, the magnetic pole is composed of two magnets, and the magnetization direction of the magnet is parallel to the center of the magnetic pole. When a current of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com