A Halbach Array Coupler

A Halbeck, array-type technology, applied in the field of magnetic induction, can solve the problems of magnetic induction line loss, magnetic drop and disappearance of couplers, etc., and achieve the effects of reducing magnetic flux leakage, reducing magnetic induction line loss, and high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

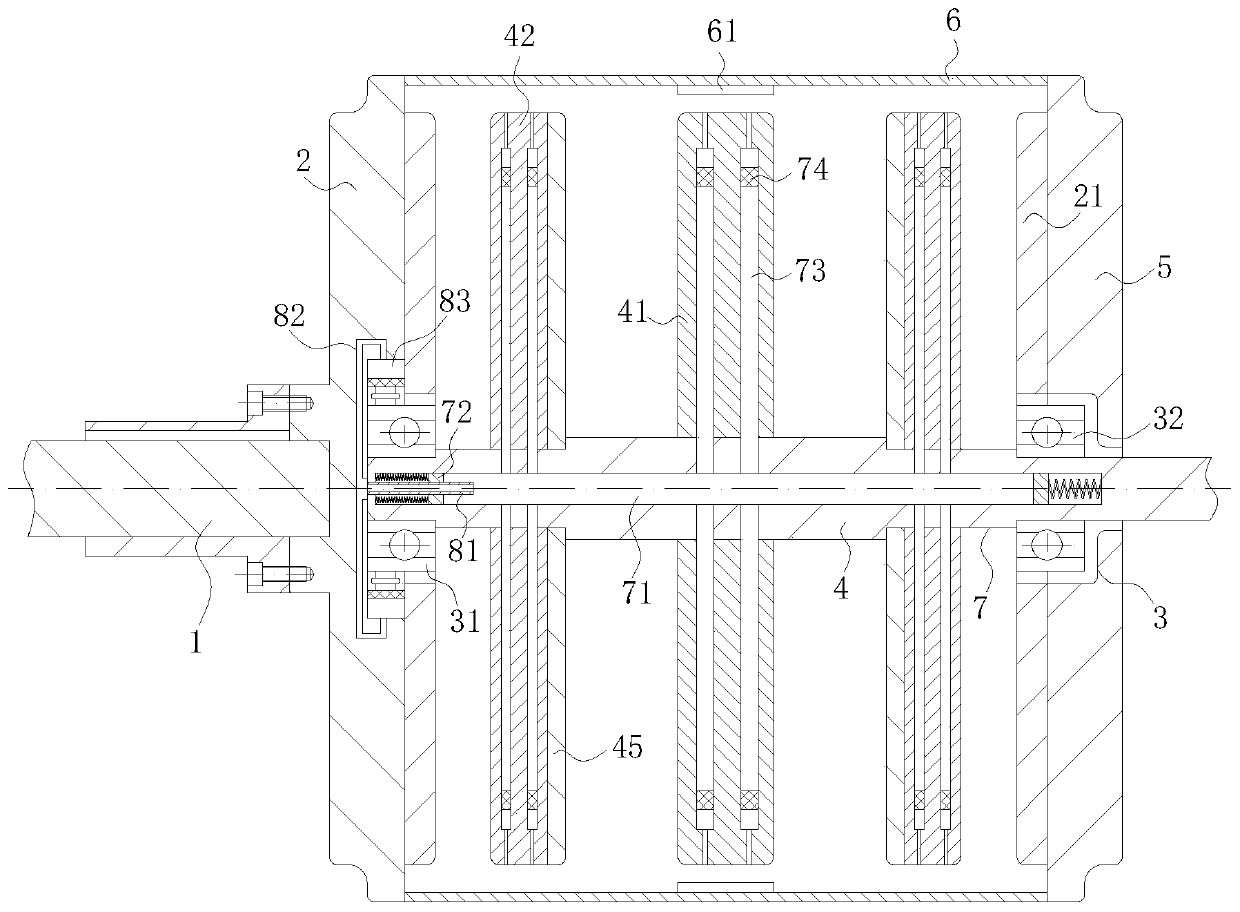

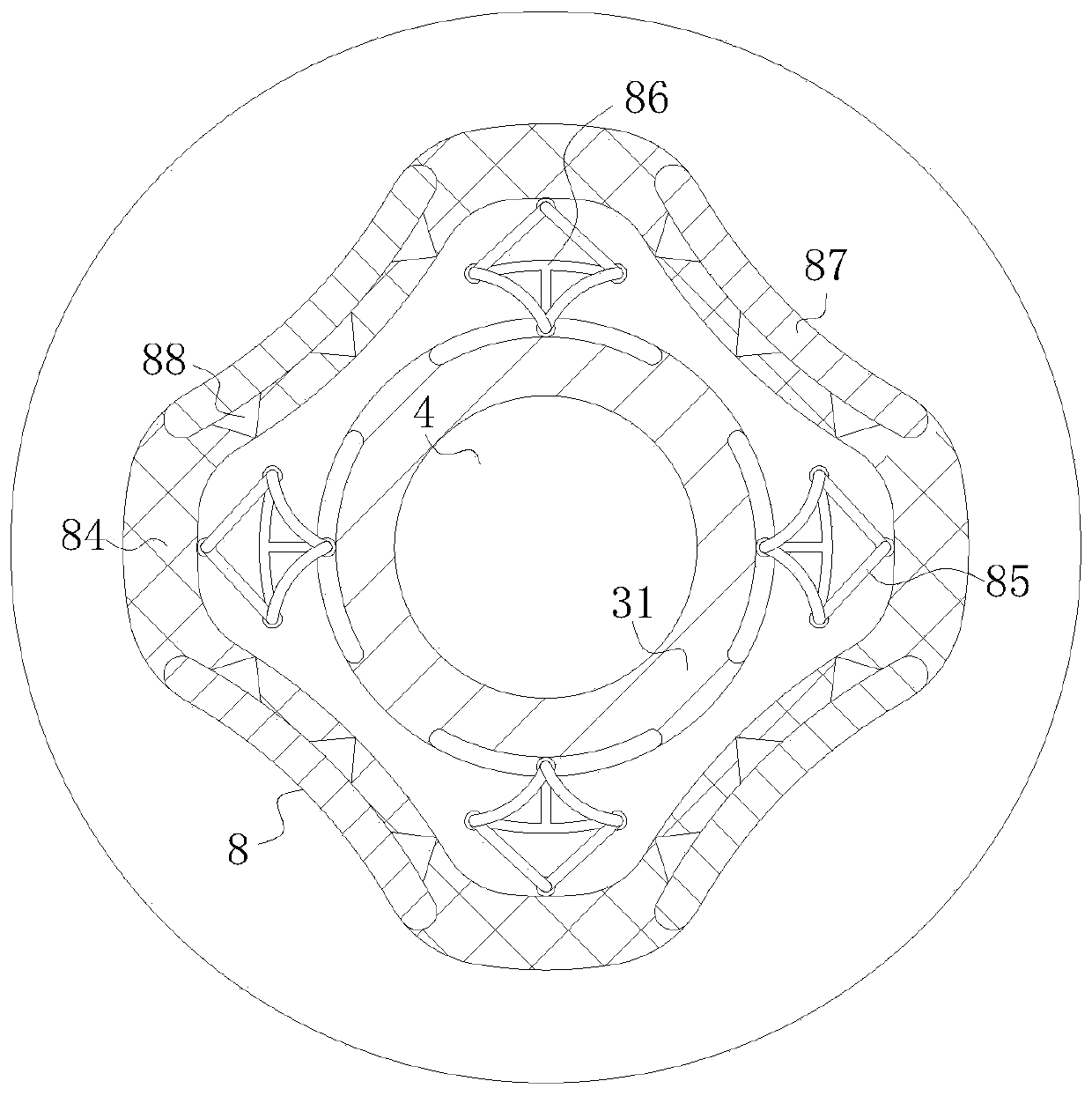

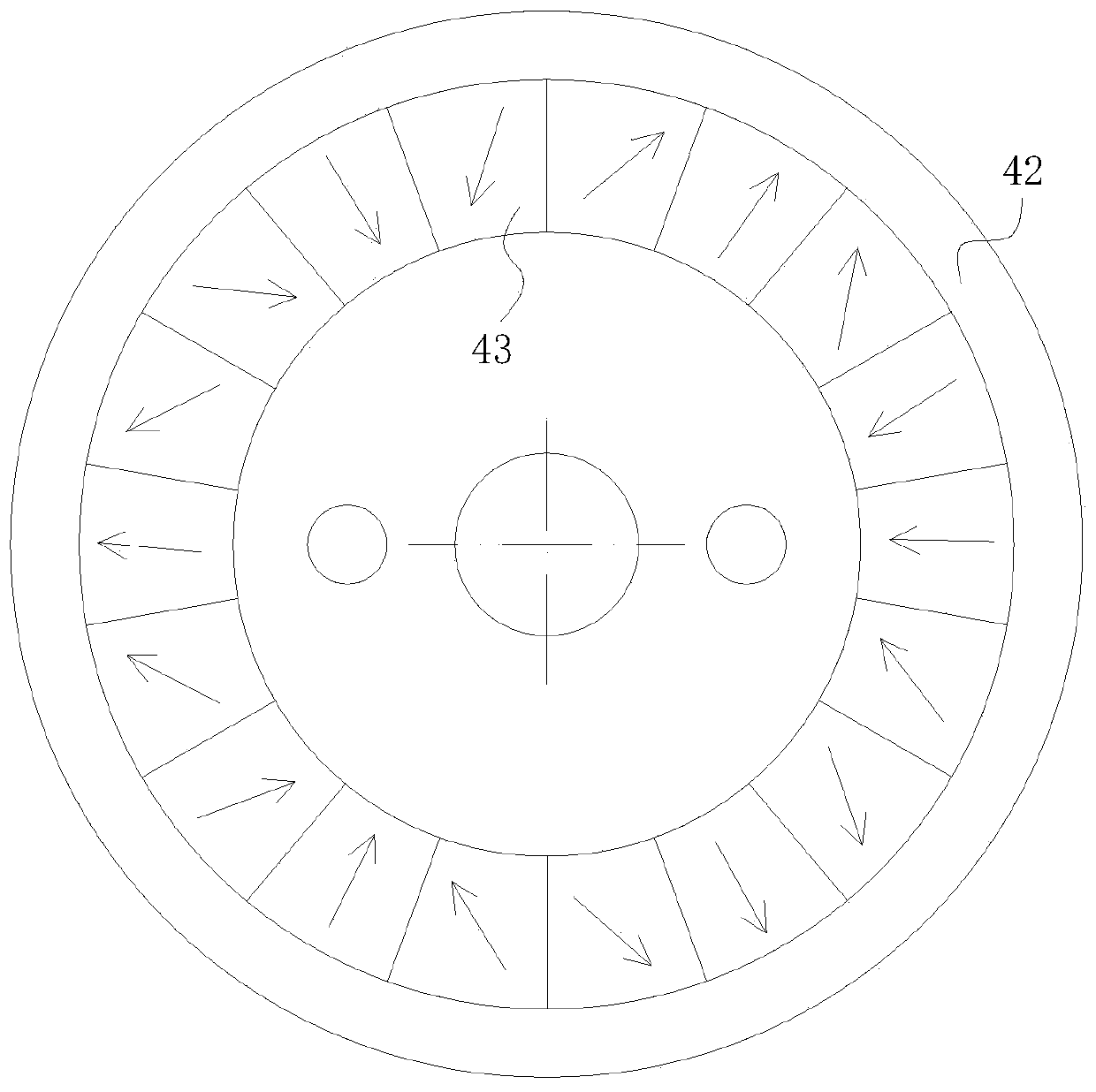

[0020] use Figure 1-Figure 4 A Halbach array coupler according to one embodiment of the present invention will be described below.

[0021] Such as Figure 1-Figure 4 As shown, a Halbach array coupler according to the present invention includes an input shaft 1, an input end cover 2, a bearing set 3, an output shaft 4, an output end cover 5, a casing 6, a cooling mechanism 7 and a buffer mechanism 8 The bearing group 3 includes a No. 1 bearing 31 and a No. 2 bearing 32; the input end cover 2 and the output end cover 5 are connected through the casing 6, and the outer end of the input end cover 2 is fixedly connected with the input shaft 1 by screws , a No. 1 bearing 31 is rotatably installed in the inner side wall of the input end cover 2, and an axial copper conductor 21 is fixedly installed on the inner surface of the input end cover 2; the inside of the No. 1 bearing 31 is fixedly connected with the output shaft 4; the output The right end of the shaft 4 is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com