Vertical power transistor and method for producing the vertical power transistor

A technology of power transistors and semiconductors, applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of changing field scale, semiconductor crystal damage, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

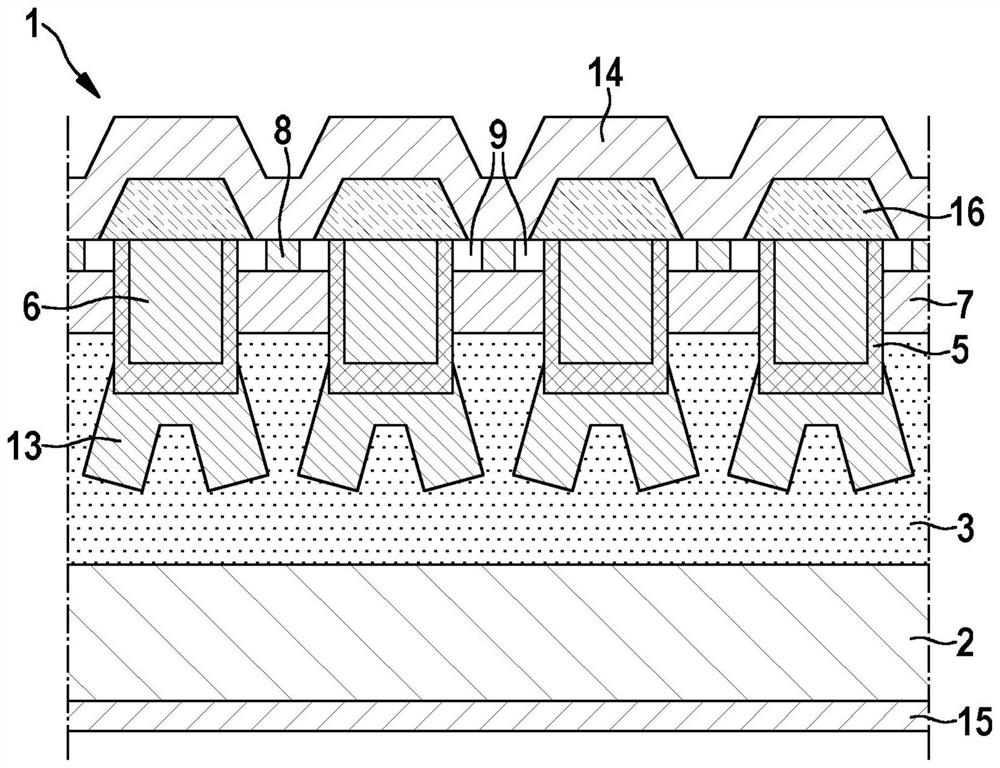

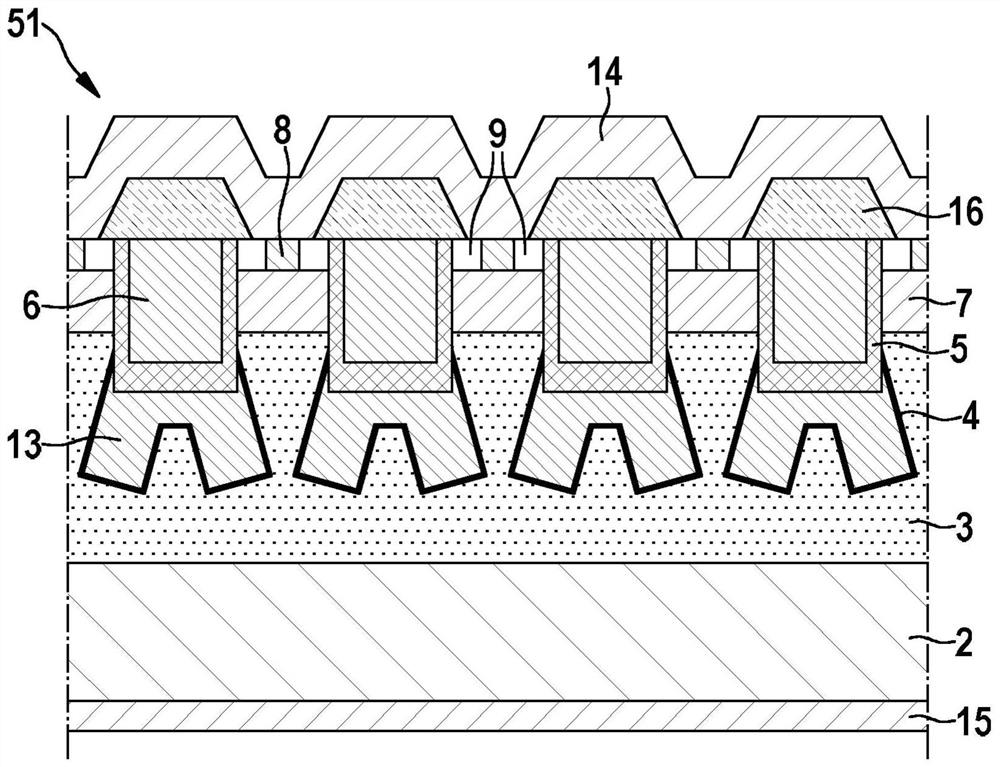

[0032] figure 1 A vertical power transistor 1 is shown having a semiconductor substrate 2 on whose front side at least one epitaxial layer 3 is arranged. The vertical power transistor 1 is, for example, a Metal Oxide Semiconductor Field Effect Transistor (Mosfet). The semiconductor substrate 2 comprises a first semiconductor material, for example silicon carbide, in particular 4H—SiC, wherein the epitaxial layer 3 is n-doped.

[0033] Arranged on the epitaxial layer 3 is a second layer 7 which functions as a channel region or body region. Arranged on the second layer 7 is a third layer comprising a body junction region 8 and a source region 9 . Arranged on the rear side of the semiconductor substrate 2 is a second metal layer 15 which functions as a drain metallization. The vertical power transistor 1 has a trench structure, that is, a plurality or a plurality of trenches. The trenches have a depth of 0.5 μm to 14 μm and a pitch of 0.2 μm to 10 μm measured at the respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com