A kind of automatic production equipment of chocolate cake for food processing

A food processing and chocolate technology, applied in the field of automatic production equipment, can solve the problems of time-consuming, laborious and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

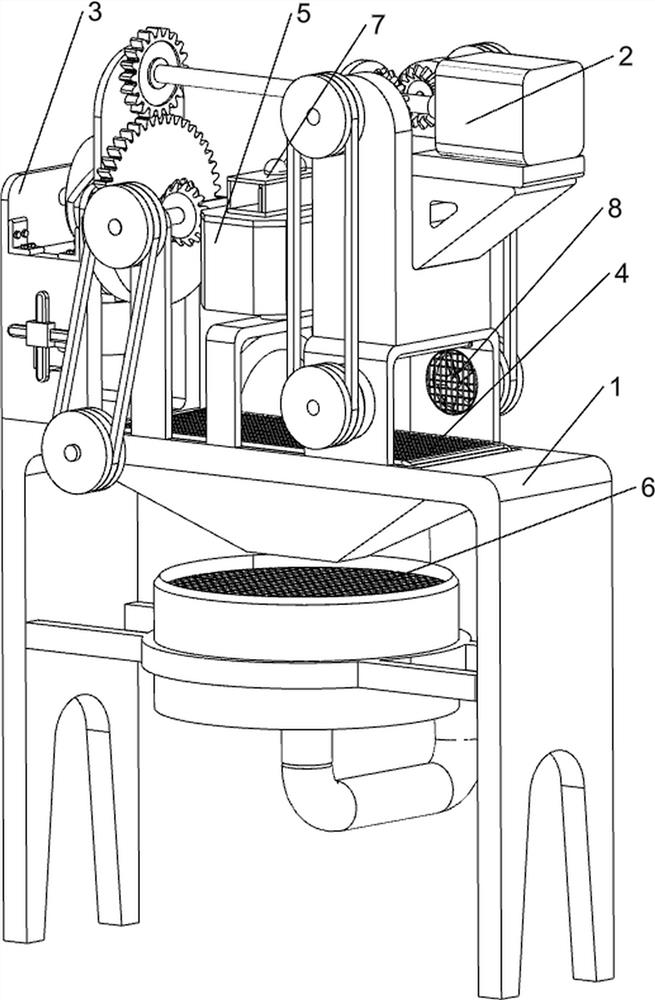

[0073] A chocolate cake automatic production equipment for food processing, such as figure 1 As shown, it includes a base 1, a motor 2, a cutting mechanism 3, a transmission mechanism 4 and a feeding mechanism 5. A motor 2 is connected to the right side of the top of the base 1, and a cutting mechanism is connected between the output shaft of the motor 2 and the left side of the top of the base 1. 3. A transmission mechanism 4 is connected between the middle of the base 1 and the cutting mechanism 3 , and a feeding mechanism 5 is connected to the base 1 .

[0074] When people need to make chocolate cakes, the bread is first placed on the cutting mechanism 3, the chocolate cream is placed in the feeding mechanism 5, and then the motor 2 is started, and the output shaft of the motor 2 rotates to drive the cutting mechanism 3 to cut the bread, and then Push the bread to the right to the transmission mechanism 4, the transmission mechanism 4 drives the bread to the right, starts t...

Embodiment 2

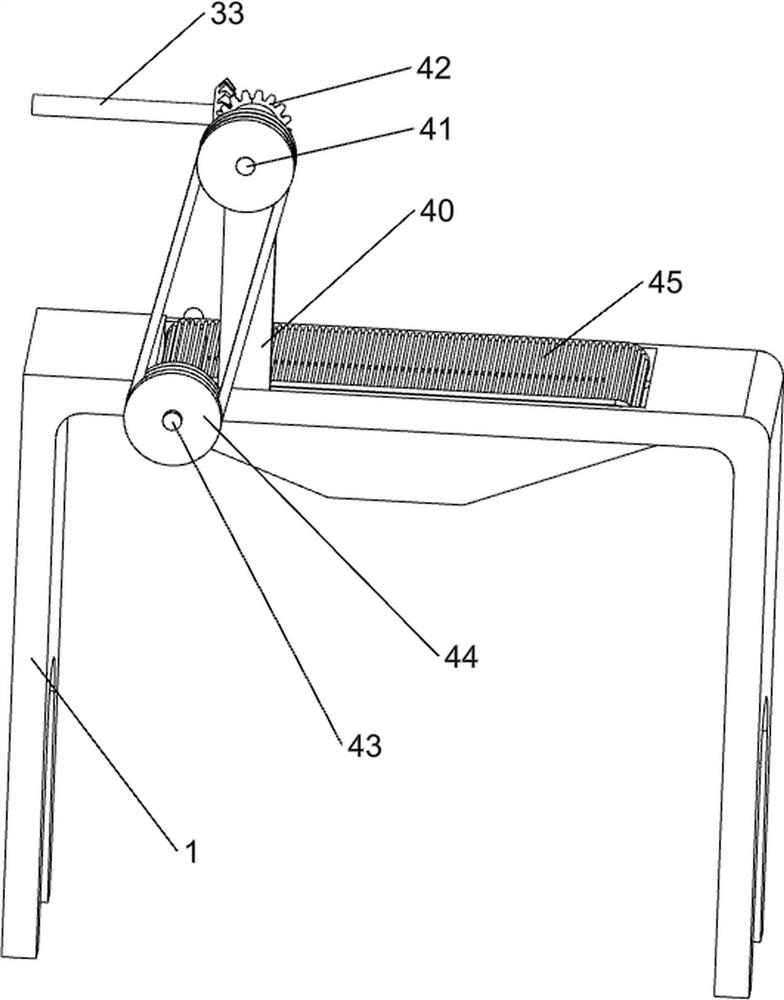

[0076] On the basis of Example 1, as Figure 2-5 As shown, the cutting mechanism 3 includes a first transmission shaft 30, a support frame 31, a second transmission shaft 32, a third transmission shaft 33, a spur gear assembly 34, a special-shaped cam 35, a support block 36, a first spring 37, a first The support rod 38, the limit block 39, the fourth transmission shaft 310 and the sheave 311, the first transmission shaft 30 is connected to the output shaft of the motor 2, the support frame 31 is connected to the left side of the top of the base 1, and the upper part of the base 1 is between the left and right sides. A second transmission shaft 32 is rotatably connected, the right side of the second transmission shaft 32 is connected with the first transmission shaft 30, the upper left side of the upper part of the support frame 31 is rotatably connected with a third transmission shaft 33, and the right side of the third transmission shaft 33 is connected with the first transmi...

Embodiment 3

[0083] On the basis of Example 2, as Figure 6-8 As shown, a filter screen 6 is also included, and the filter screen 6 is connected to the upper side of the first storage cylinder 51 .

[0084] The chocolate cream that flows back to the first storage cylinder 51 from the transmission assembly 45 for recycling will carry bread crumbs, pass through the filter screen 6, and stay on the filter screen 6, which can play a filtering role.

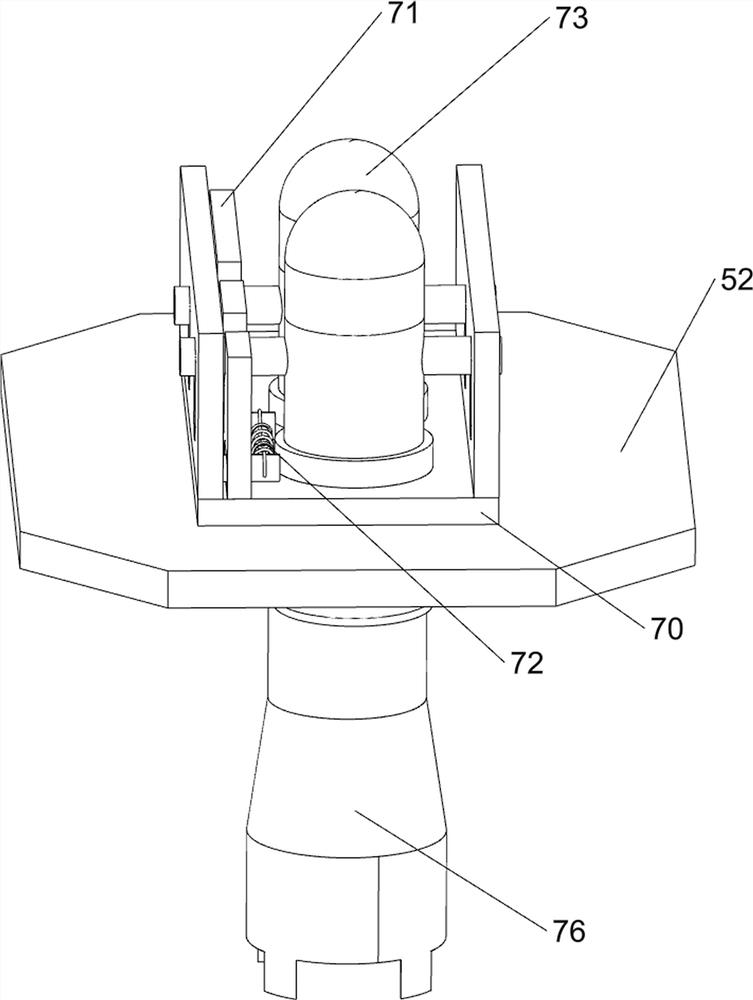

[0085] It also includes a control mechanism 7. The control mechanism 7 includes a support plate 70, a slider 71, a second spring 72, a first control block 73, a third spring 74, a piston 75, a protective cylinder 76, a second control block 77 and a first control block 77. Four springs 78 , a support plate 70 is connected to the top of the second storage cylinder 52 , a slider 71 is slidably connected to the right side of the support plate 70 , and a second spring 72 is connected between the left rear side of the slider 71 and the support plate 70 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com