Electric bagasse flashboard control device

A control device and ram technology, applied in the field of sugarcane sugar industry equipment, can solve the problems of inability to control the combustion rate of bagasse into the furnace, boiler combustion efficiency, impact on energy saving and consumption reduction, dust pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

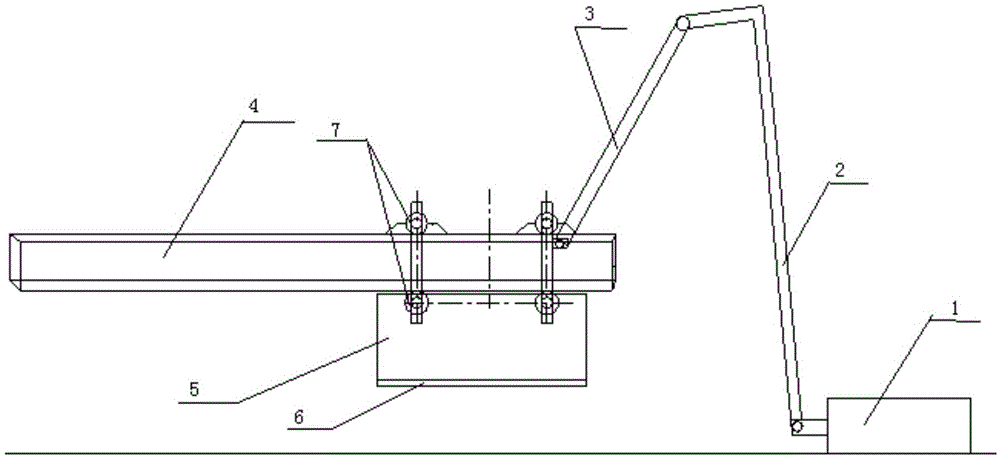

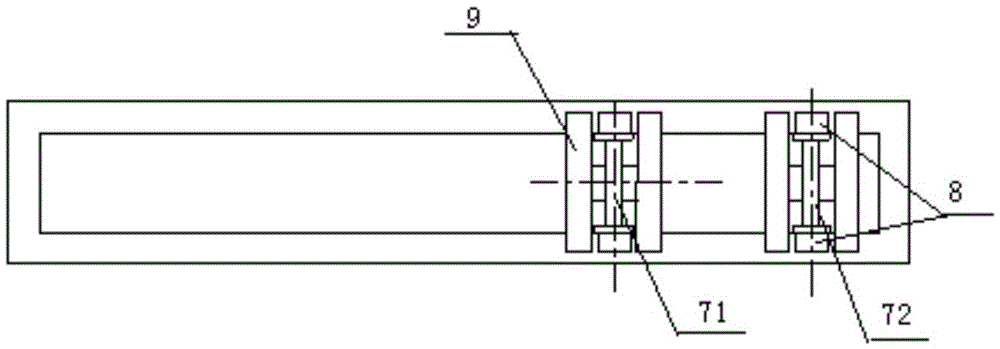

[0012] Attached below Figure 1-2 The present invention will be described with reference to Examples.

[0013] Electric bagasse ram control device, including servo motor (1), fixed connecting rod (2), push rod (3), bracket (4), ram (5), rubber plate (6), limit device (7) , limit bearing (8), slag scraper (9), the output end of the servo motor (1) is fixedly connected to one end of the fixed connecting rod (2), and the other end of the fixed connecting rod (2) is hinged to one end of the push rod (3) , the other end of the push rod (3) is hinged with the front limiting device (72), the gate (5) is fixed on the bracket through the front limiting device (71) and the rear limiting device (72), and the limiting device (7) Limiting bearings (8) are welded at the upper and lower ends, the slag scraper (9) is welded on the upper end of the limiting device (7), and the rubber plate (6) is fixed on the lower end of the flashboard (5). The servo motor (1) drives the fixed connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com